Elastic shoe

A technology of elastic shoes and shrapnel, applied in the field of elastic shoes, can solve problems such as insufficient ventilation, peculiar smell, and insufficient comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

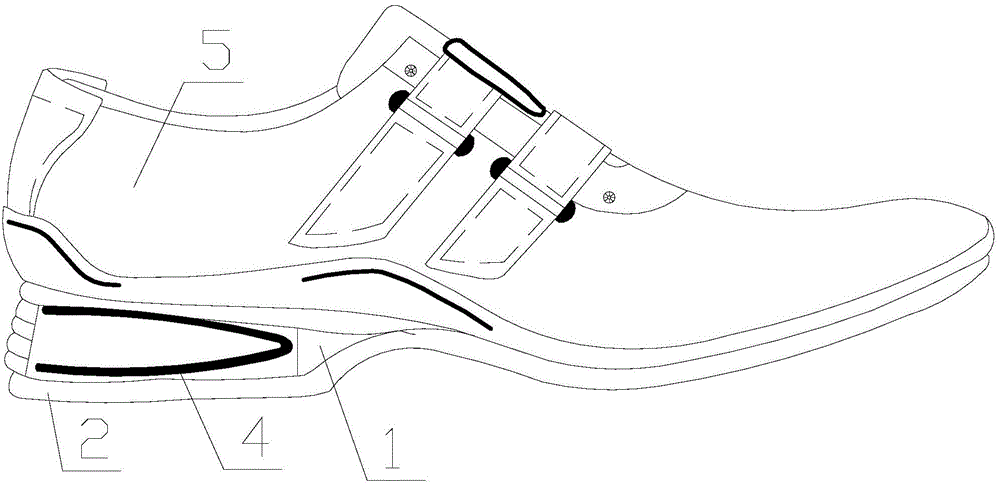

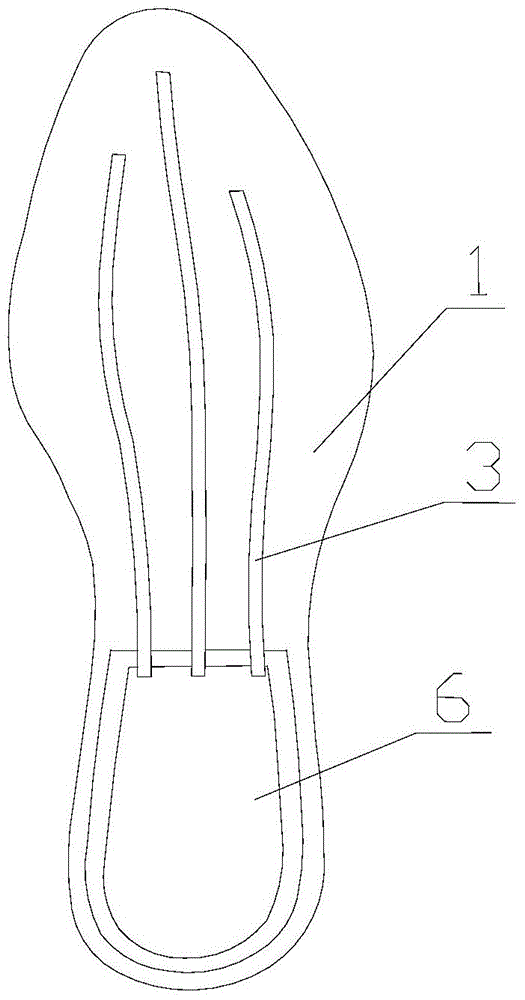

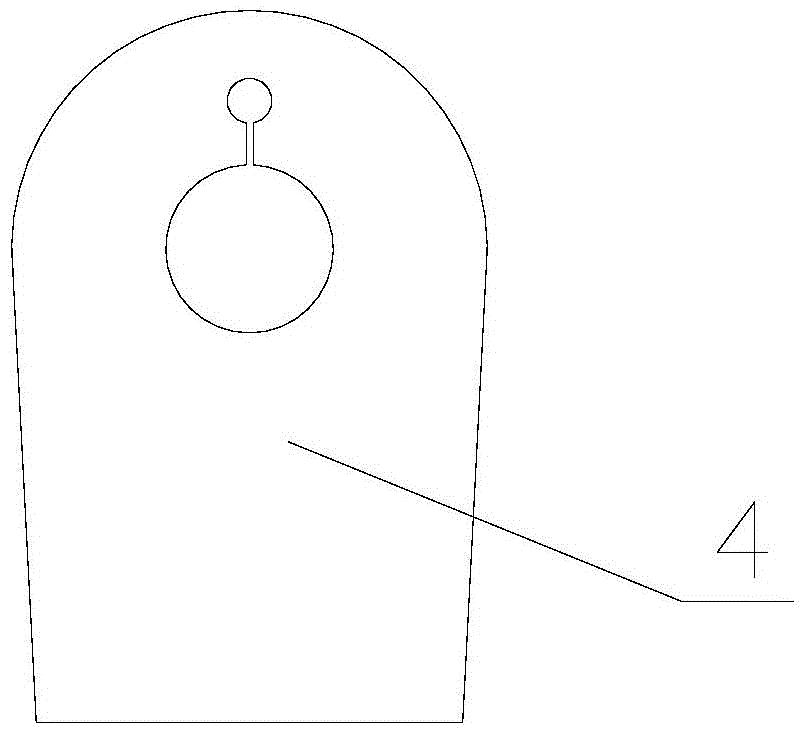

[0013] Such as Figure 1 to Figure 4 As shown, a high-elastic shoe includes a sole 1 provided with a heel, the sole 1 and the upper 5 are connected by sewing thread or glue, a shrapnel chamber 6 is arranged in the heel, and a shrapnel 4 is arranged in the shrapnel chamber 6, and the shrapnel 4 is provided with a bottom plate 2, the bottom plate 2 is connected with the shrapnel chamber 6 and the bottom surface of the heel to form an integral structure, the upper surface of the forefoot of the sole 1 is provided with air holes, and a trachea 3 is provided between the air holes and the shrapnel chamber 6 of the heel and passes through the trachea 3. The shrapnel cavity 6 communicates with the air hole provided on the upper surface of the heel or the inner surface of the upper 5 .

[0014] In this embodiment, the heel of the shoe is made of a material that can produce elastic deformation under certain pressure, such as modified plastics, natural rubber, polyurethane or tendon rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com