Large-outer-diameter hot plate of vulcanizing machine and preparation method for large-outer-diameter hot plate

A vulcanizing machine and large outer diameter technology, applied in the field of vulcanizing machines, can solve the problems of inability to meet the needs of large-scale projects, uneven heat transfer, large splicing gaps, etc., and achieve the effects of low cost, uniform heat transfer, and small splicing welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0058] In order to achieve the purpose of the present invention, in some of the embodiments of the large outer diameter vulcanizer hot plate and its preparation method,

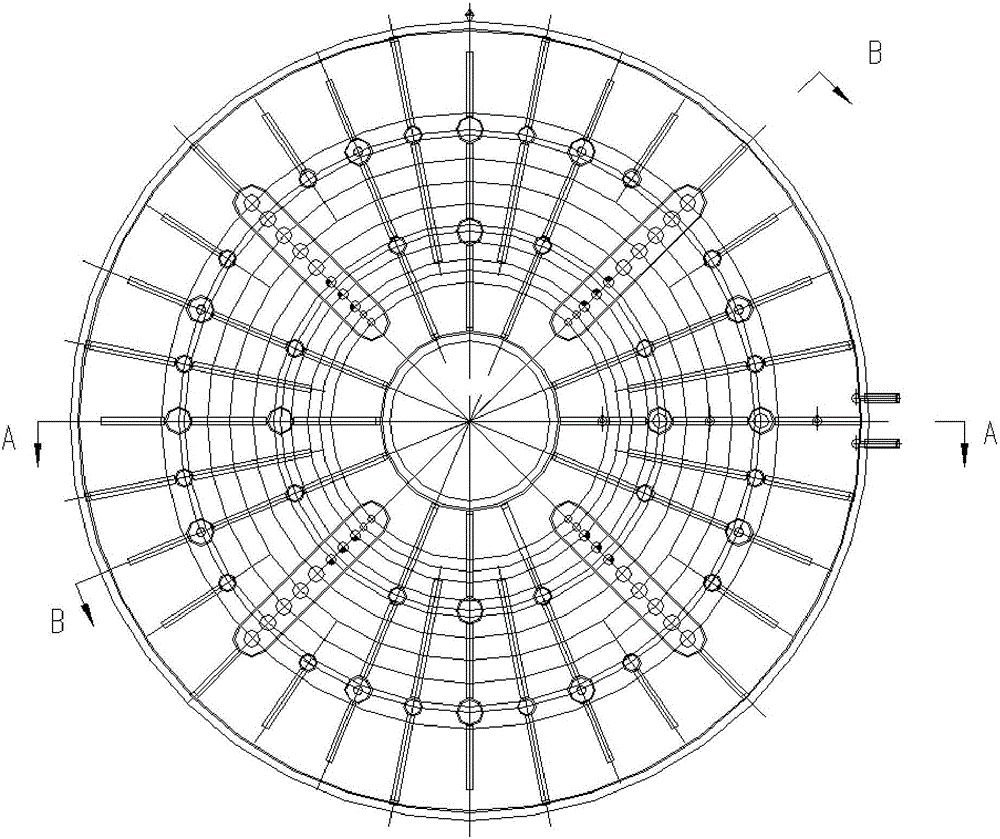

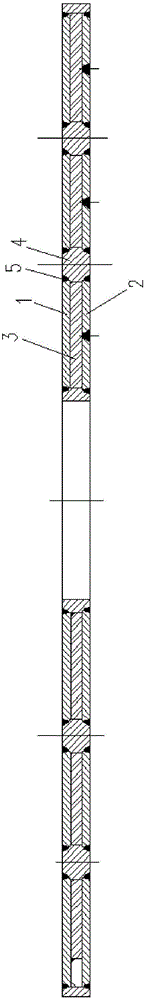

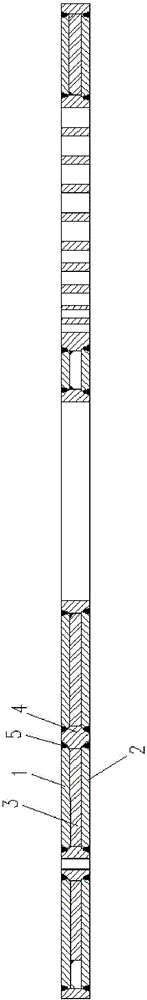

[0059] Such as Figure 1-3 As shown, the upper hot plate is made of the hot plate of the large outer diameter vulcanizer. The hot plate of the large outer diameter vulcanizer includes a plurality of hot plate units arranged in order from the inside to the outside, and each hot plate unit includes: a multi-layer structure splicing Unit and the enclosure 4 arranged on the outside of the splicing unit. The splicing unit includes: a first panel 1, a second panel 2, and a rib 3 arranged between the first panel 1 and the second panel 2, in the first panel 1 and A groove weld 5 is provided at the butt joint of the second panel 2 and the enclosure plate 4, and the first panel 1 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com