Cloth receiving device for raising machine

A technology of raising machine and mounting frame, which is applied in the directions of transportation and packaging, folding thin materials, thin material processing, etc., can solve the problems of wasting manpower and low folding neatness, and achieve the effect of continuous folding, labor saving, and neat folding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

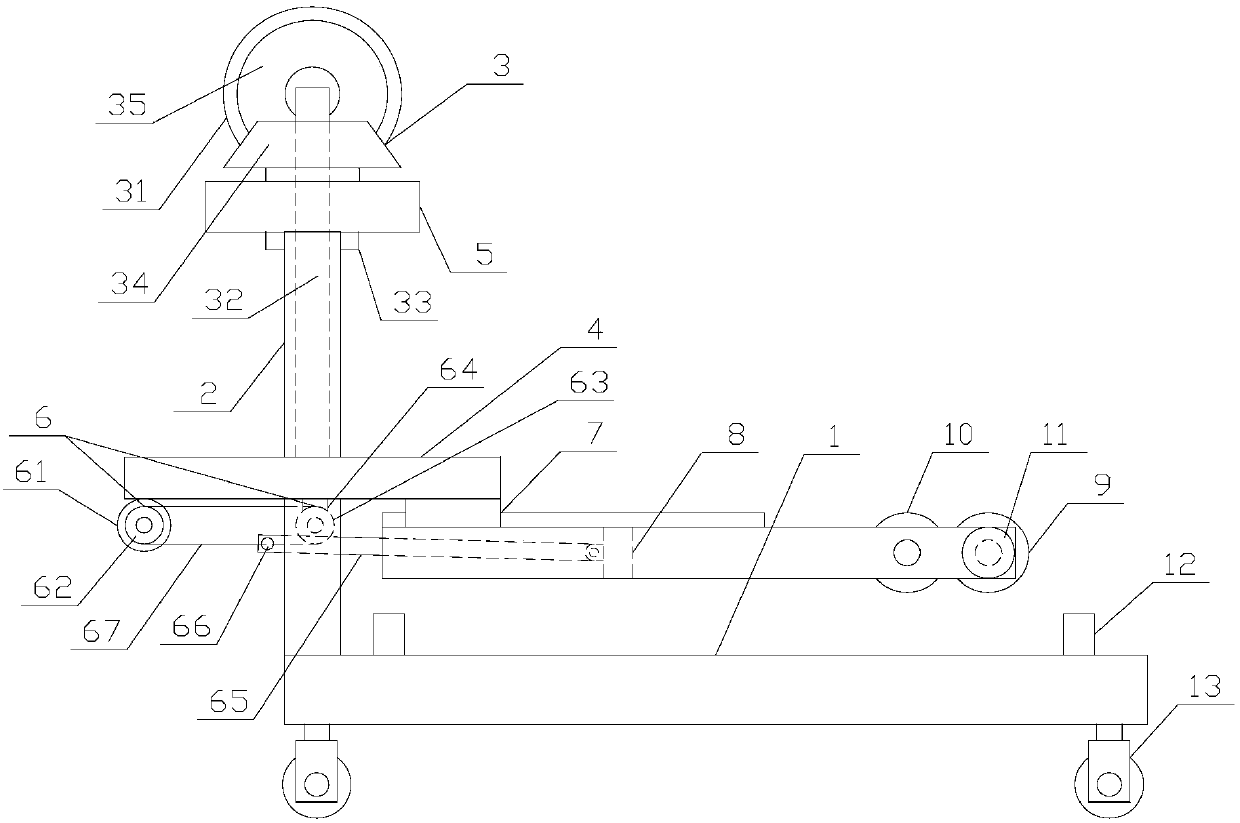

[0012] refer to figure 1 , a cloth receiving device of a raising machine according to the present invention, comprising a base 1, a sliding column 2, a first driving mechanism 3, a sliding seat 4, a connecting plate 5, a second driving mechanism 6, a slideway 7, a mounting frame 8, and a driving roller 9. The driven roller 10 and the first motor 11. The front part of the base 1 is provided with two symmetrical sliding columns 2, and the upper end of the sliding column 2 is equipped with a connecting plate 5, and the connecting plate 5 is provided with There is a first driving mechanism 3, and a slidable sliding seat 4 is installed on the sliding column 2, and the first driving mechanism 3 drives the sliding seat 4 to move, and the bottom of the sliding seat 4 is provided with a second driving mechanism 6 and Two symmetrical slideways 7, the second driving mechanism 6 is arranged in front of the slideway 7, the mounting frame 8 is installed on the slideway 7, and the second dri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap