An image module positioning jig and method thereof

A technology of image module and positioning fixture, which is applied in image communication, TV, color TV components, etc., can solve the problems of improving user experience, increasing cost, and restricting the use and development of closed-loop motors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

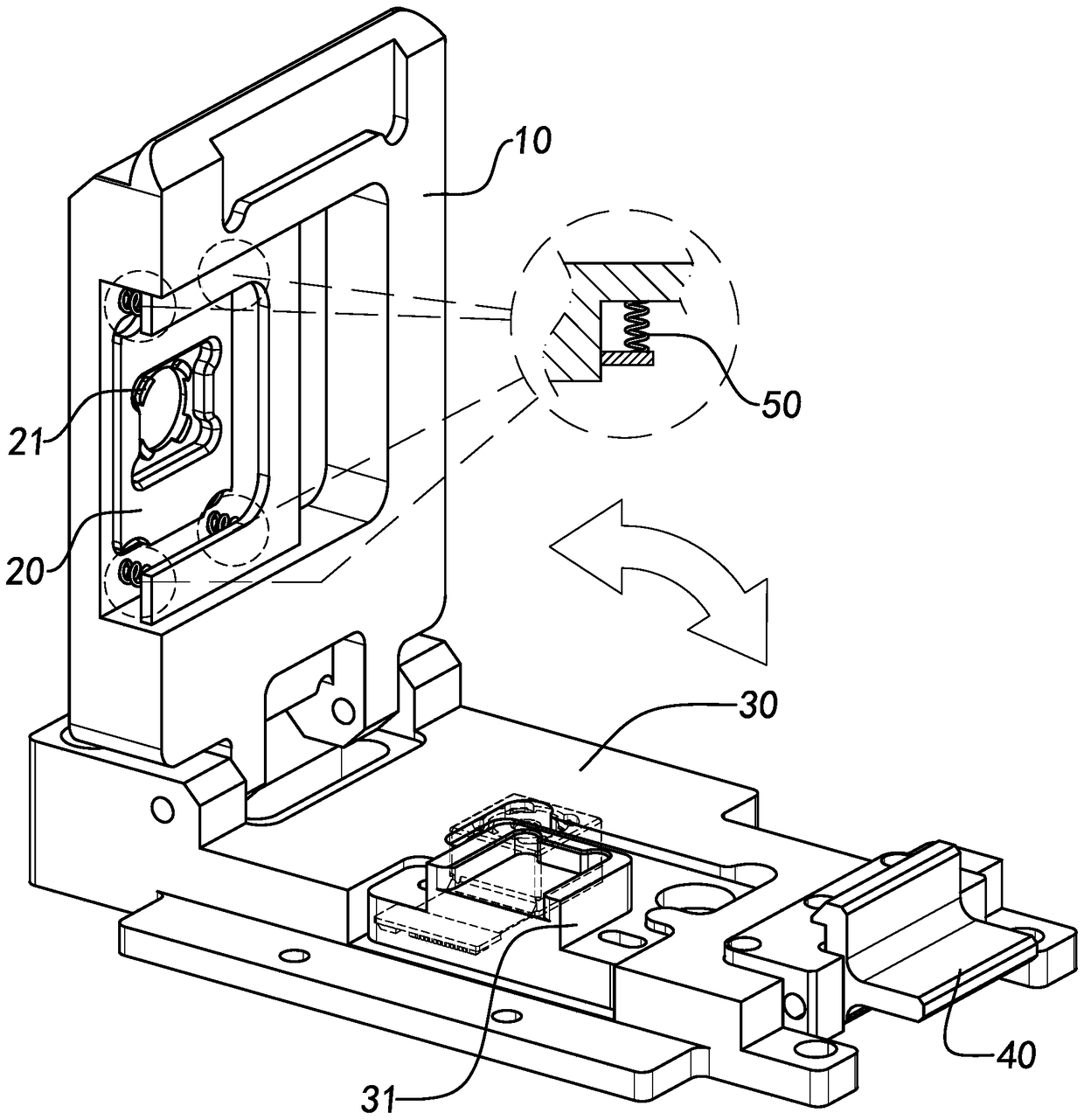

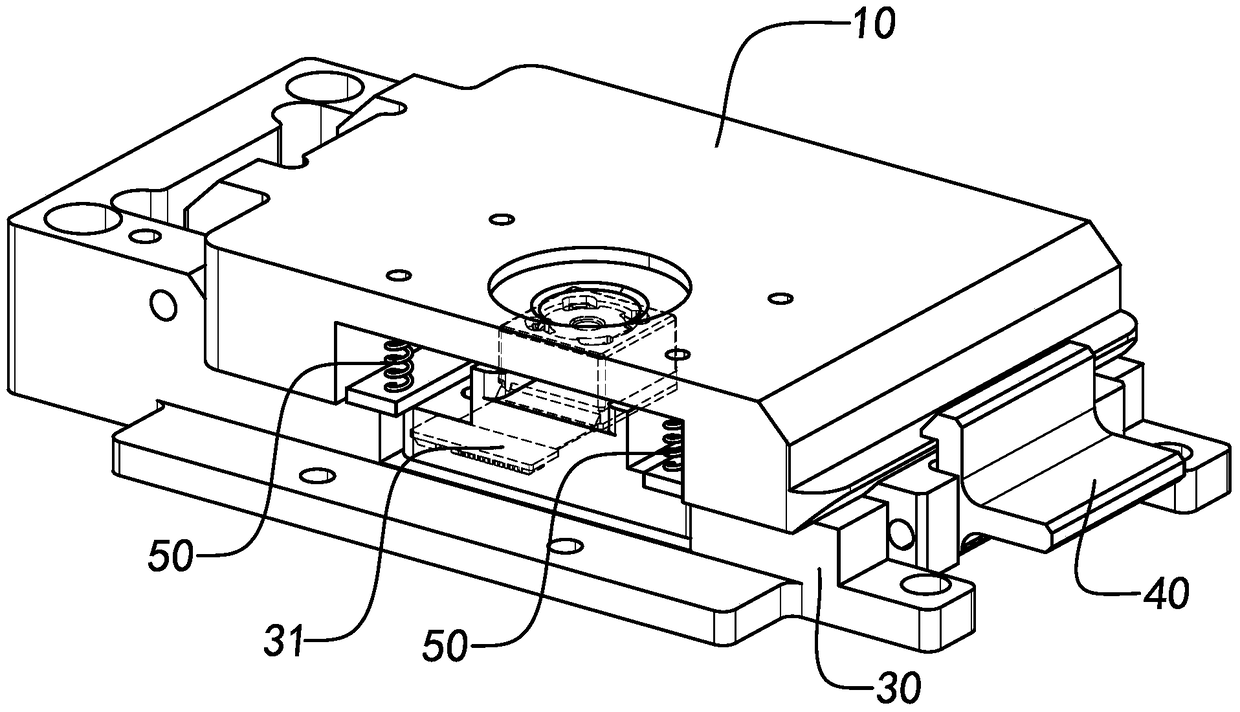

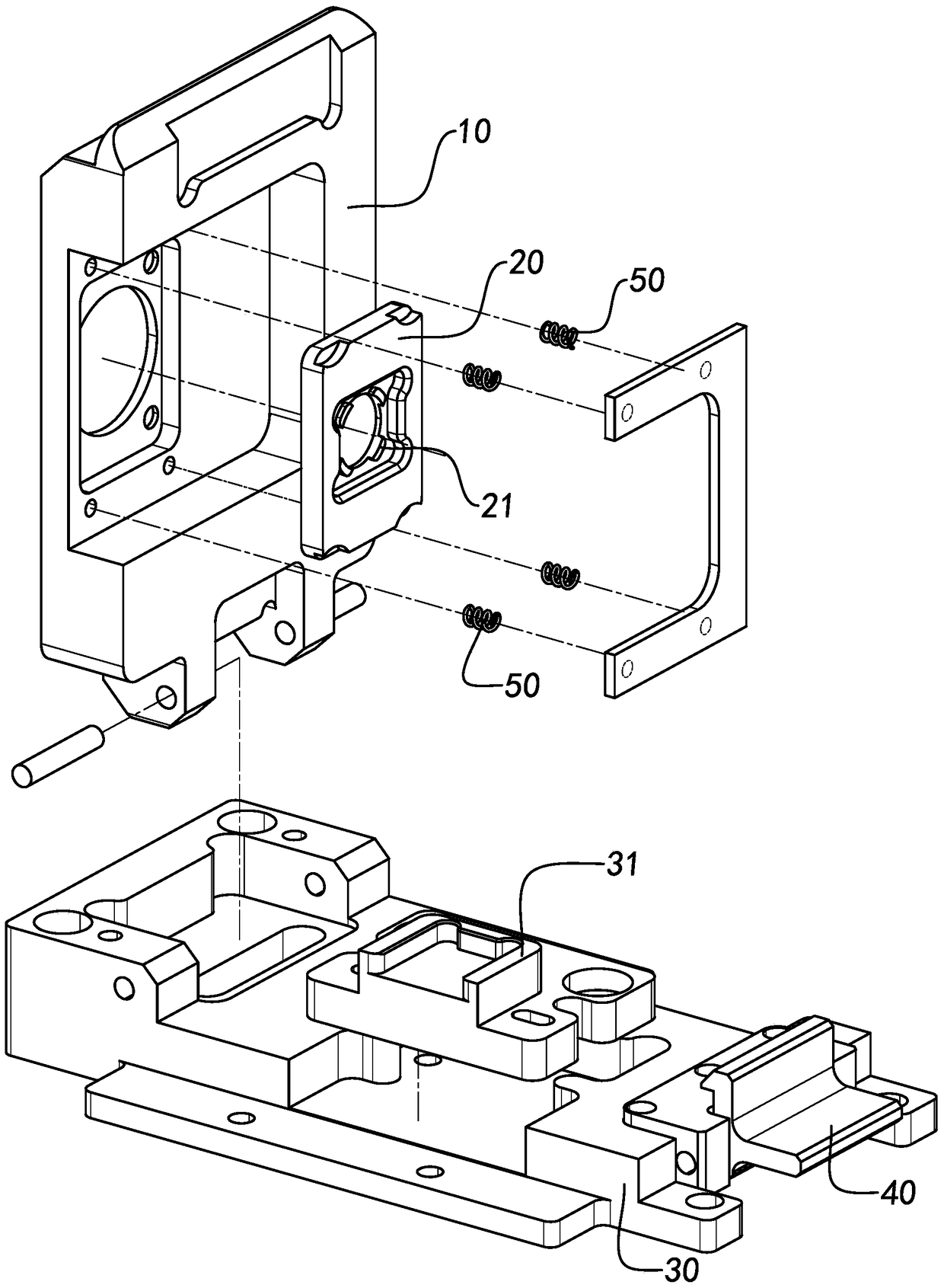

[0052] According to the claims of the present invention and the content disclosed in the specification, the technical solution of the present invention is specifically described as follows.

[0053] like Figure 1 to Figure 2 Shown is a preferred embodiment of an image module positioning jig of the present invention, the image module positioning jig can be used for positioning each component of at least one image module before focusing, and the components include a closed-loop Motors and other optical and electronic components, etc., while the image module positioning fixture can ensure the flatness of the components, it can also press the motor mover of the closed-loop motor to the motor of the closed-loop motor bottom.

[0054] It is worth mentioning that there are magnets in the motor mover of the closed-loop motor, so that the motor mover can only achieve precise positioning under the action of external force to ensure the accuracy of subsequent focusing and other actions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com