Gas-liquid mixer

A gas-liquid mixing and mixing chamber technology, which is used in gas/vapor and liquid mixing, mixers, mixing methods, etc., can solve problems such as low safety, gas or liquid leakage, and inability to ensure uniform gas or liquid mixing, etc. Achieving the best application prospects and the effect of a wide range of adaptations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

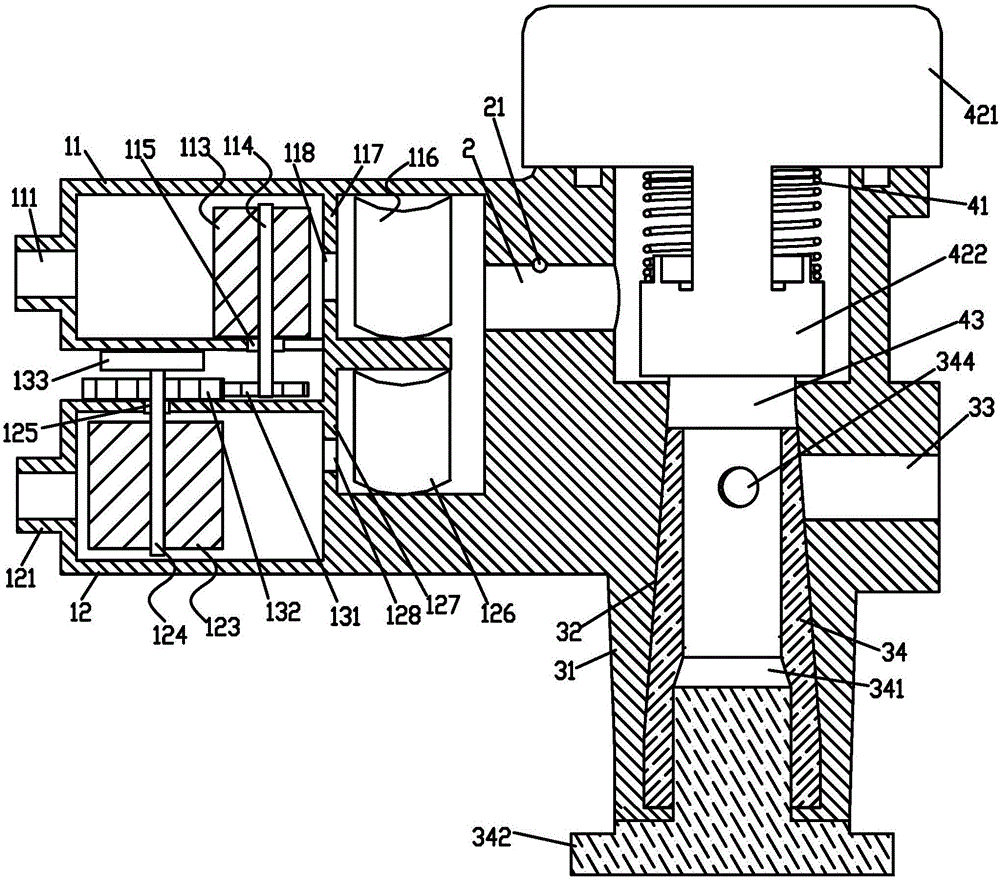

[0017] like figure 1 As shown, the present invention proposes a gas-liquid mixing device with high safety, uniform mixing and wide adaptability, including an input part having a plurality of input channels, a mixing chamber 2 communicating with each input channel of the input part, connecting The switch part of the mixing chamber 2 and the switch controller for controlling whether the mixing chamber 2 communicates with the switch part, the switch controller is arranged between the mixing chamber 2 and the switch part.

[0018] The following takes the input unit with 2 input channels as an example for further description. The input part comprises: a first input channel 11 having a first input interface 111 for liquid or gas to enter and a second input channel 12 having a second input interface 121 for liquid or gas to enter, the first input channel 11 and the second input channel 11 The input channels 12 are all communicated with the mixing chamber 2; the first impeller 113 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com