A Laser Template Polishing Fixture

A technology of polishing fixtures and laser templates, which is applied in the direction of electrolysis, electrolysis components, etc., can solve the problems of time waste and cost increase, and achieve the effect of convenient polishing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

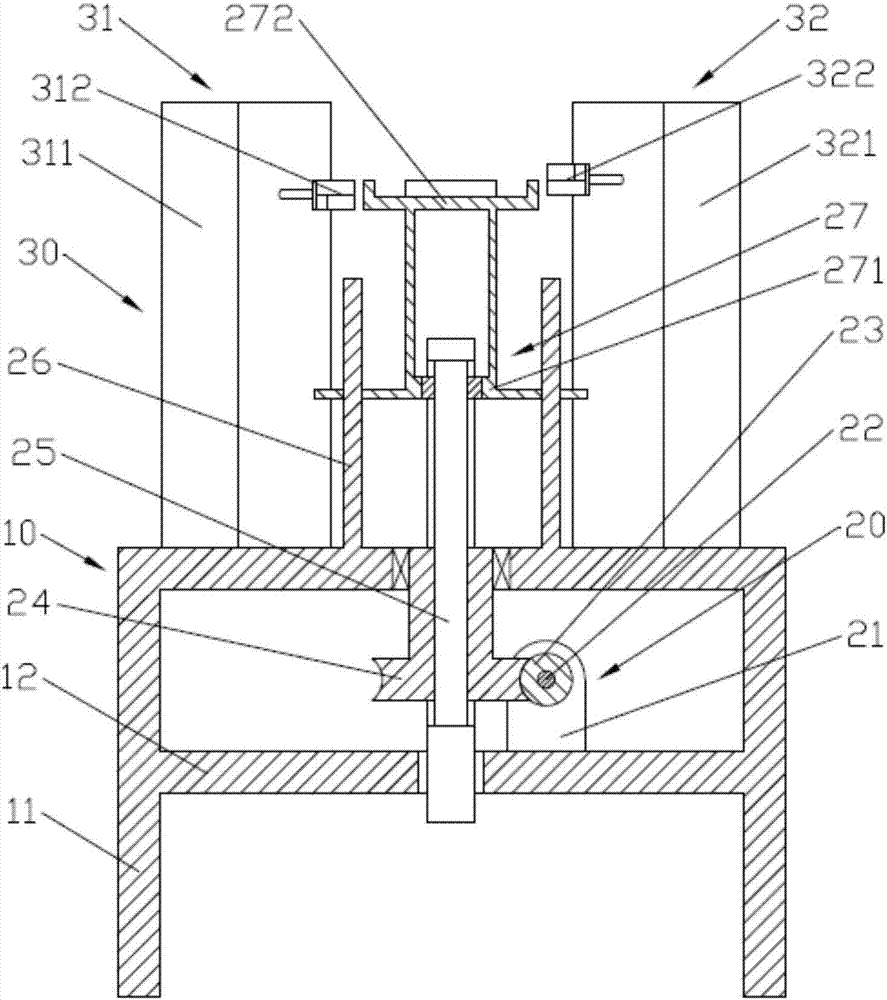

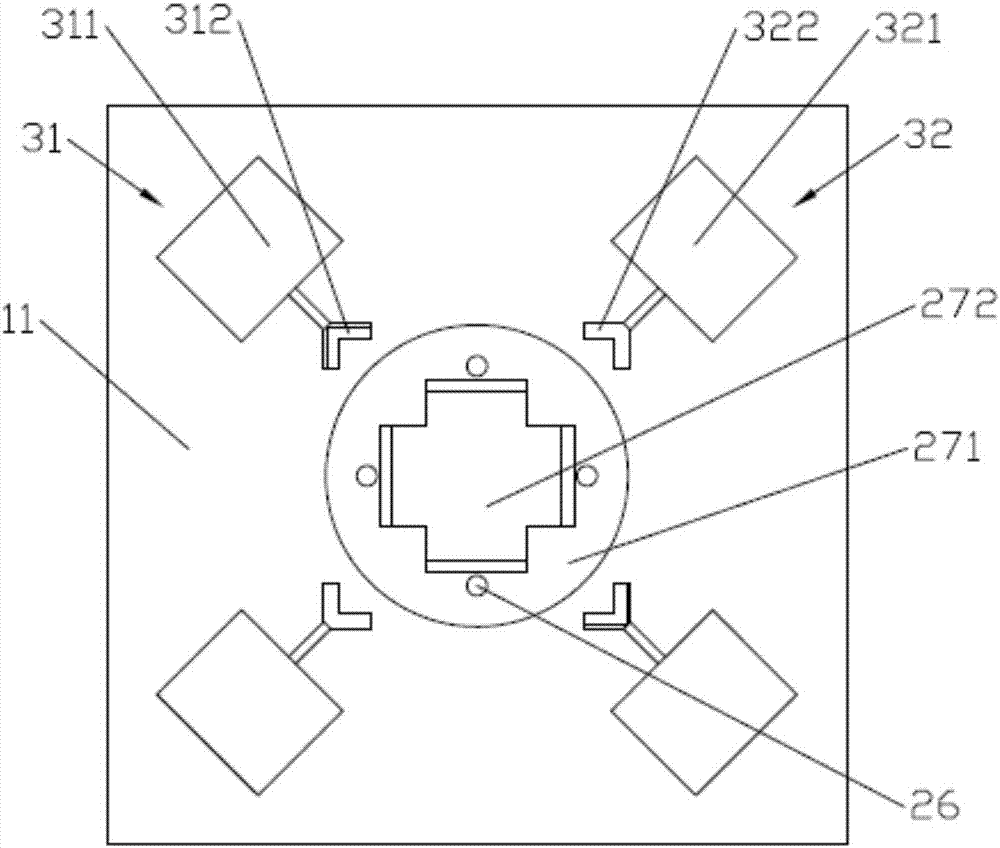

[0018] like Figure 1 ~ Figure 2 As shown, a laser template polishing fixture includes a frame 10, a template lifting device 20 and a template clamping device 30; the frame 10 includes a frame body 11 with an empty cavity inside; the frame body 11 is horizontally provided with a fixed Plate 12; four guide rods 26 are vertically fixed on the upper end surface of the frame body 11;

[0019] like Figure 1 ~ Figure 2 As shown, the template lifting device 20 includes a first worm 23, a central transfer block 24, a threaded rod 25 and a template placement unit 27; a pair of support seats 21 are vertically fixed on the upper end surface of the fixed plate 12; the first worm 23 passes through the central axis 22 longitudinally Pivoted on the support seat 21; the upper part of the central transmission block 24 is a cylinder, and the lower part is a worm gear; the central transmission block 24 is formed with a threaded hole penetrating from top to bottom; the upper part of the central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com