Double waterproof structure for lens

A waterproof structure and lens technology, applied in the field of lens, can solve problems such as many defective products, inability to adjust real-time focus, glue overflow, etc., and achieve good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

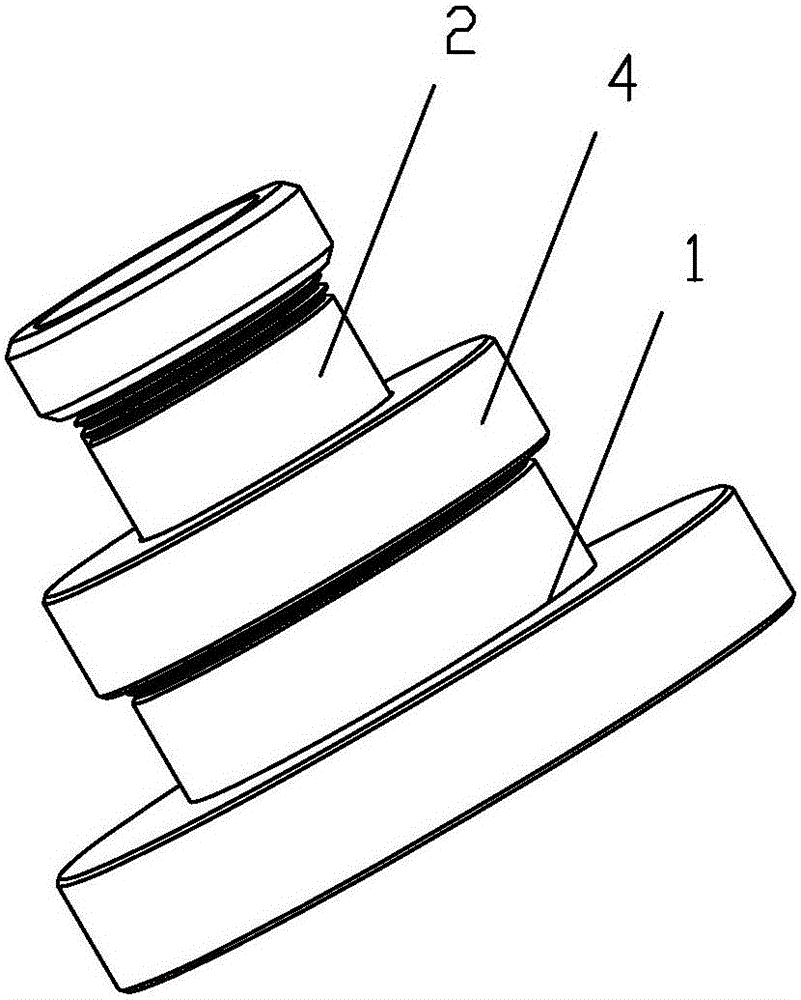

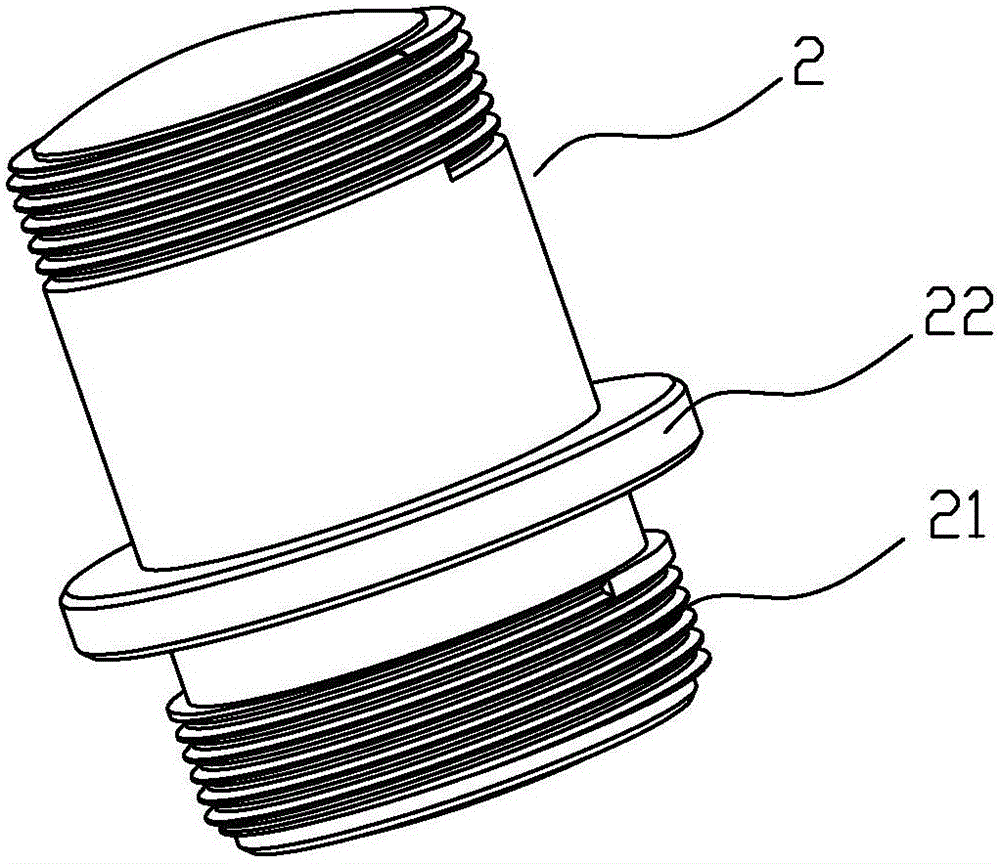

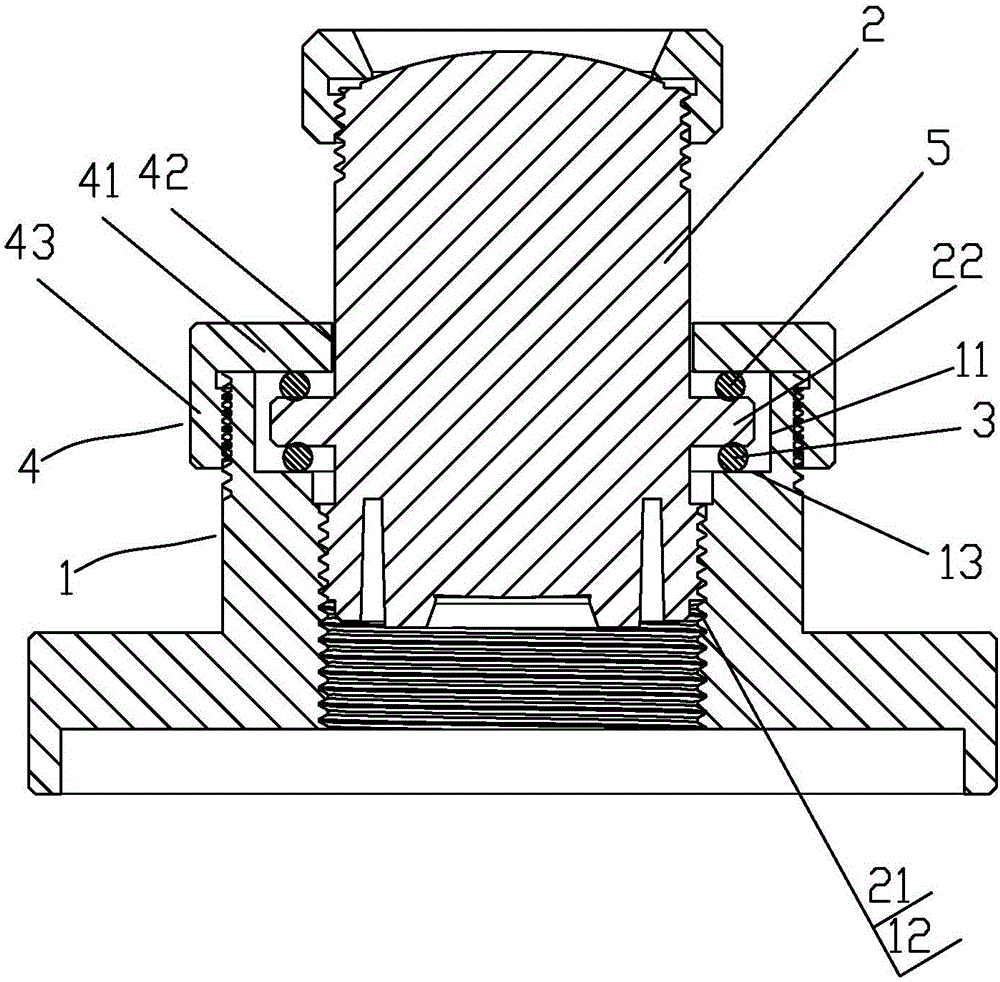

[0016] A double waterproof structure of a lens, comprising a lens support tube 1, the lens support tube 1 includes an upper space section 11 and an internal thread section 12, the inner diameter of the upper space section 11 is greater than the inner diameter of the internal thread section 12, and the A step surface 13 is formed at the junction of the upper space section 11 and the internal thread section 12. The lens body 2 is provided in the lens support tube 1, and one end of the lens body 2 is provided to cooperate with the internal thread section 12 to enable the lens body to 2. The body threaded section 21 that moves axially in the lens support tube 1. The middle part of the lens body 2 is provided with an annular boss 22 protruding from its outer peripheral surface. One side of the annular boss 22 is connected to the stepped surface 13 A first sealing ring 3 for wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com