Motor stator slot-sealing mechanism and motor stator slot-sealing machine

A motor stator and slot machine technology, applied in the field of motor processing, can solve the problems of low efficiency, low quality and reliability, etc., and achieve the effect of simple action, high reliability and compact overall structure

Active Publication Date: 2016-07-13

HANGZHOU TIANMING TECH CO LTD

View PDF6 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there is currently no slot sealing machine that can automatically complete the entire slot sealing process designed for the slot wedge paper sl

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

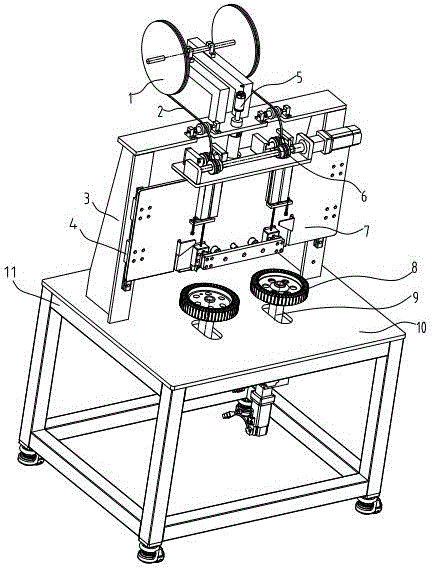

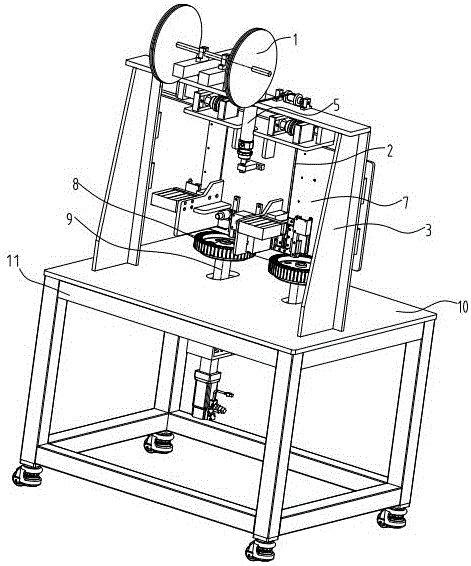

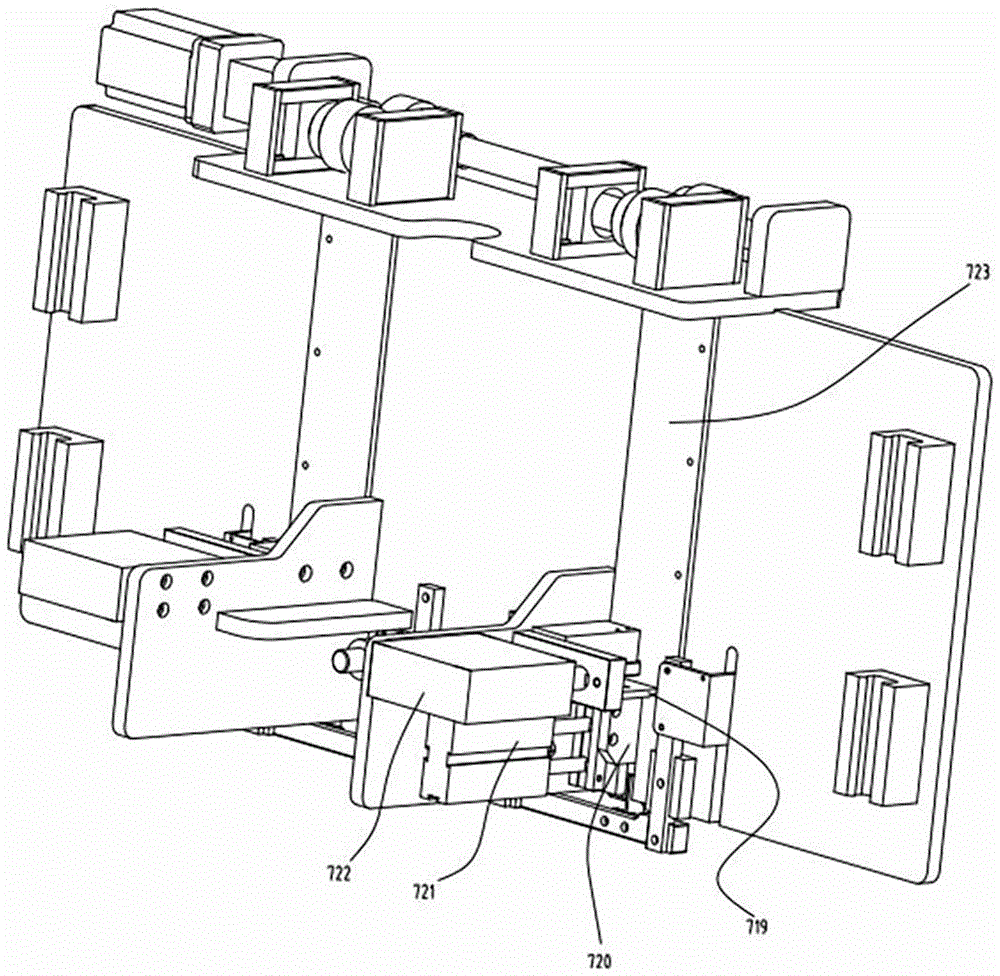

The invention belongs to the technical field of motor machining and discloses a motor stator slot-sealing mechanism and a motor stator slot-sealing machine. The motor stator slot-sealing machine comprises a frame, a slot wedge paper carrier disc, a slot-sealing mechanism, and a stator support mechanism, wherein the slot wedge paper carrier disc, the slot-sealing mechanism, and the stator support mechanism are disposed on the frame. The slot-sealing mechanism comprises a paper feeding device for pulling slot wedge paper strips out of a slot wedge paper roll and feeding the slot wedge paper strips downwardly, a cutting-off device for cutting off the slot wedge paper fed by the paper feeding device, a molding device for extrusion molding the cut-off unformed slot wedge paper, and a slot wedge inserting device for pushing formed slot wedge paper out of the molding device and inserting the slot wedge paper into the sealed motor stator slot. The slot-sealing machine achieves automation of slot wedge paper insertion by designing the paper feeding device, the cutting-off device, the molding device, and the slot wedge inserting device in a combined way. The motor stator slot-sealing mechanism and the motor stator slot-sealing machine are compact in overall structure, simple in operation, and high in reliability.

Description

technical field [0001] The invention belongs to the technical field of motor processing, and relates to motor stator processing equipment, in particular to equipment for sealing motor stator winding slots. Background technique [0002] Existing motor stators are usually sealed with bamboo wedges, epoxy plate slot wedges or injection molded slot wedges. The first two kinds are not conducive to the automation of inserting wedges, while the ordinary injection molding slot wedges limit the insulation level of the motor below class B, and the use of high temperature injection molding slot wedges will increase the cost significantly. Compared with the above three kinds of slot wedges, the method of sealing the motor stator with rolls of slot wedge paper as the raw material is not only easy to ensure that the insulation level of the motor is F level and above, but also the cost is significantly lower than ordinary Injection molded wedges. But, also do not have at present the slot...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02K15/00

CPCH02K15/0018

Inventor 卿兆波杨惠忠

Owner HANGZHOU TIANMING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com