Anti-skid shoe soles

A large-sole, uniform technology, applied in the field of shoe-making equipment, can solve the problems that the direction and strength of deformation are not very comfortable, cannot be adjusted, and the anti-skid effect is not good enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

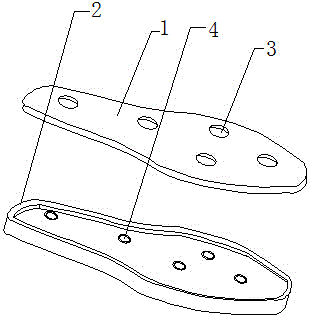

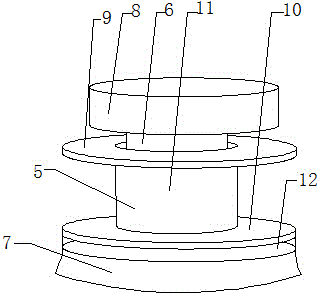

[0014] Such as figure 1 and figure 2 A kind of non-slip sole shown, comprises outsole 1 and midsole 2, and described midsole 2 is embedded in the outsole 1; The described midsole 2 is provided with circular groove 3; The described outsole 1 is provided with The round groove 3 is in the through hole 4 in the same direction; the through hole 4 is equipped with a work-shaped seat 5; the middle of the work-shaped seat 5 is embedded with a rubber column 6; the front side of the rubber column 6 is integrally formed with a rubber seat 7; the back side of the rubber column 6 is bonded with a silica gel column 8; the silica gel column 6 is fitted into the circular groove 3.

[0015] The work-shaped seat 5 is integrally made of the upper disc 9, the lower disc 10 and the cylinder 11; the center of the upper disc 9, the lower disc 10 and the cylinder 11 is provided with a through hole; the upper disc 9 and the The inner surface of the lower disc 10 is bonded to the top surface and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap