Cam clamping device

A technology of clamping device and wedge, applied in the direction of workpiece clamping device, manufacturing tools, etc., can solve the problems of too long force arm of the pressure plate, large geometric size, and torque generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

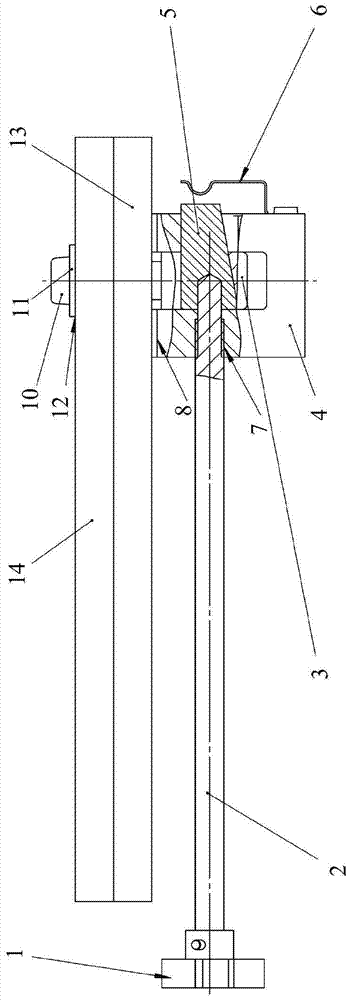

[0014] The above-mentioned features and advantages of the present invention can be better understood after reading the detailed description of the embodiments of the present disclosure in conjunction with the following drawings. In the drawings, components are not necessarily drawn to scale, and components with similar related properties or characteristics may have the same or similar reference numerals.

[0015] figure 1 The structure of a preferred embodiment of the wedge clamping device of the present invention is shown. See figure 1 , the wedge clamping device of this embodiment includes a handle 1, a wedge 5, a fixing frame 4, a fixing piece 3, and a stud 2, wherein the handle 1 is installed on one end of the stud 2, and the other end of the stud 2 passes through the fixing frame The threaded hole 7 of 3 enters the wedge hole of the wedge 5, the fixing part 3 is installed in the long groove of the fixing frame 4, the fixing part 3 has an oblique square hole, and the obl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com