A garbage conveying device

A technology of garbage conveying and garbage hopper, applied in the field of garbage conveying device, can solve the problems of insufficient secondary energy recovery, environmental pollution, complex structure, etc., and achieve the effect of improving work efficiency, saving investment and space occupation, and having strong mobility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

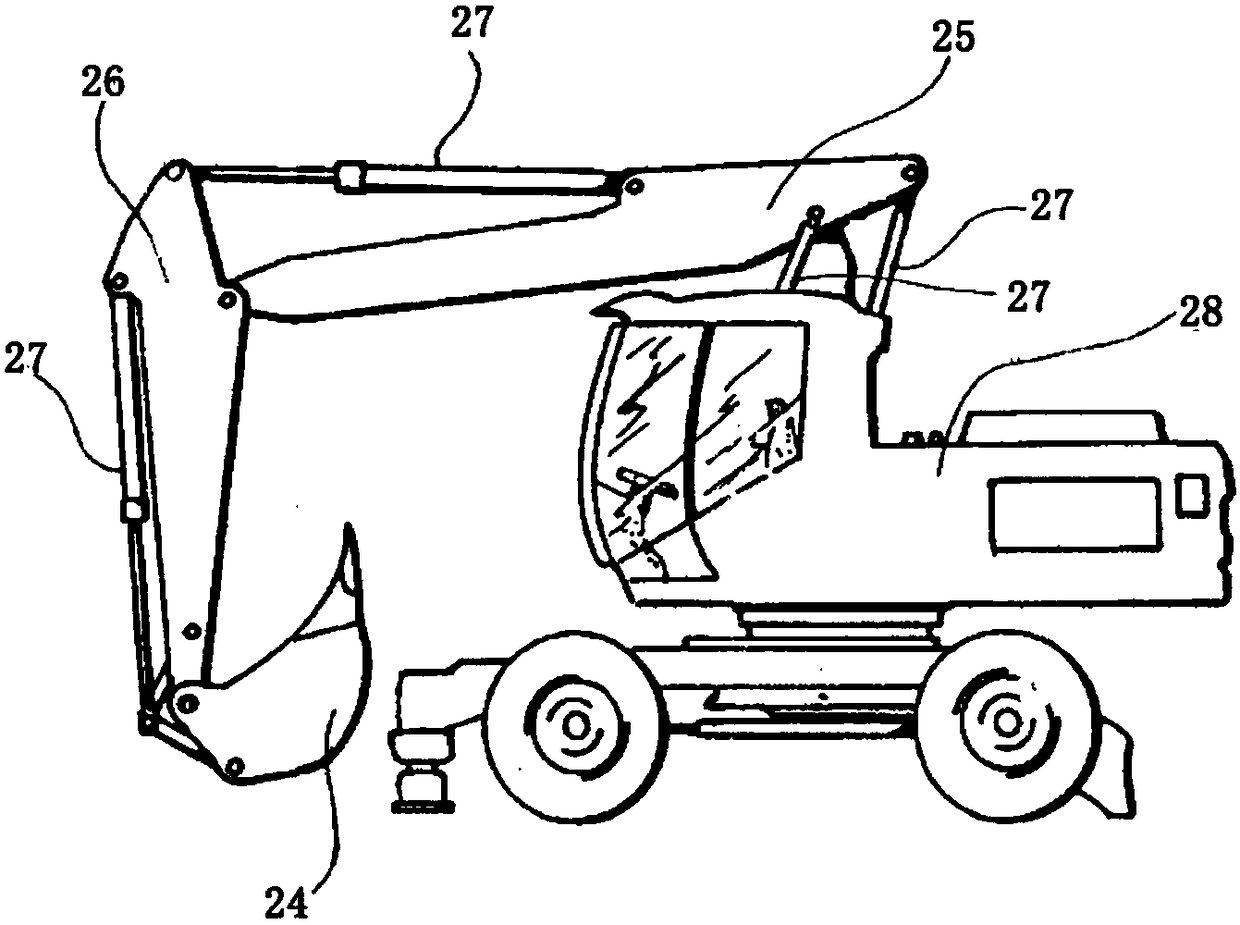

[0021] Such as figure 1 A kind of garbage conveying device shown, comprises car body 28, garbage hopper 24, first mechanical arm 25, second mechanical arm 26, hydraulic rod 27 and engine system, described car body 28, first mechanical arm 25, the first mechanical arm The two mechanical arms 26 and the garbage bucket 24 are sequentially hingedly connected; a plurality of said hydraulic rods 27 are successively installed between the vehicle body 28 and the first mechanical arm 25, between the first mechanical arm 25 and the second mechanical arm 26, and between the second mechanical arm 25 and the second mechanical arm 26. Between the mechanical arm 26 and the garbage bucket 24 is used to drive the first mechanical arm 25 , the second mechanical arm 26 and the garbage bucket 24 to move; the vehicle body 28 is driven by the engine 2 .

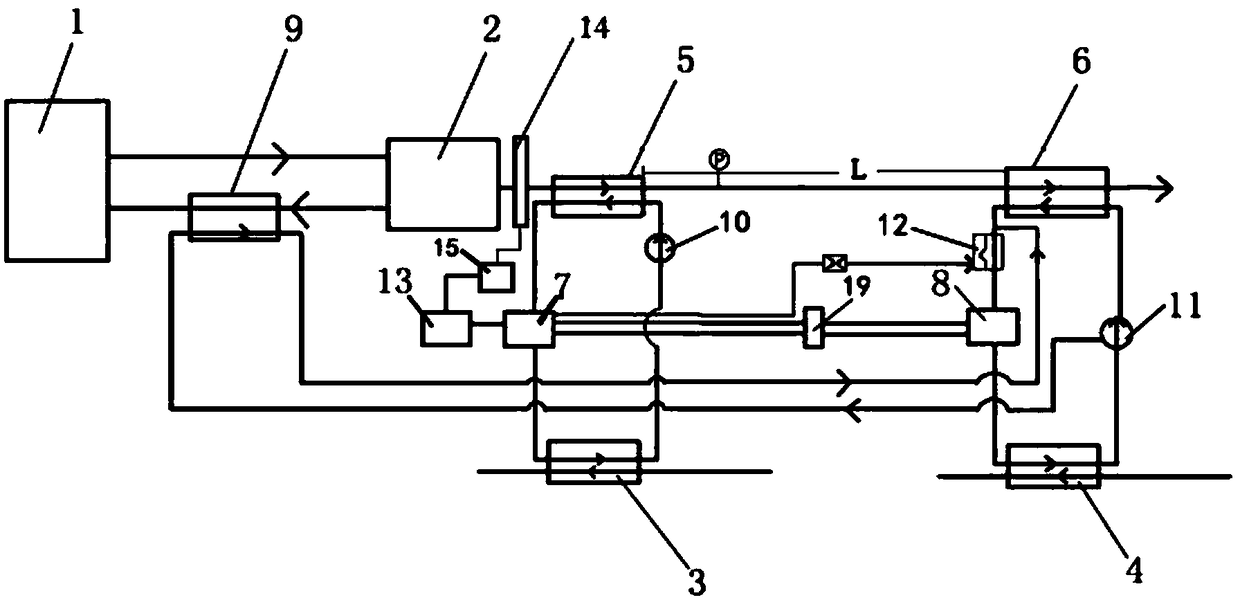

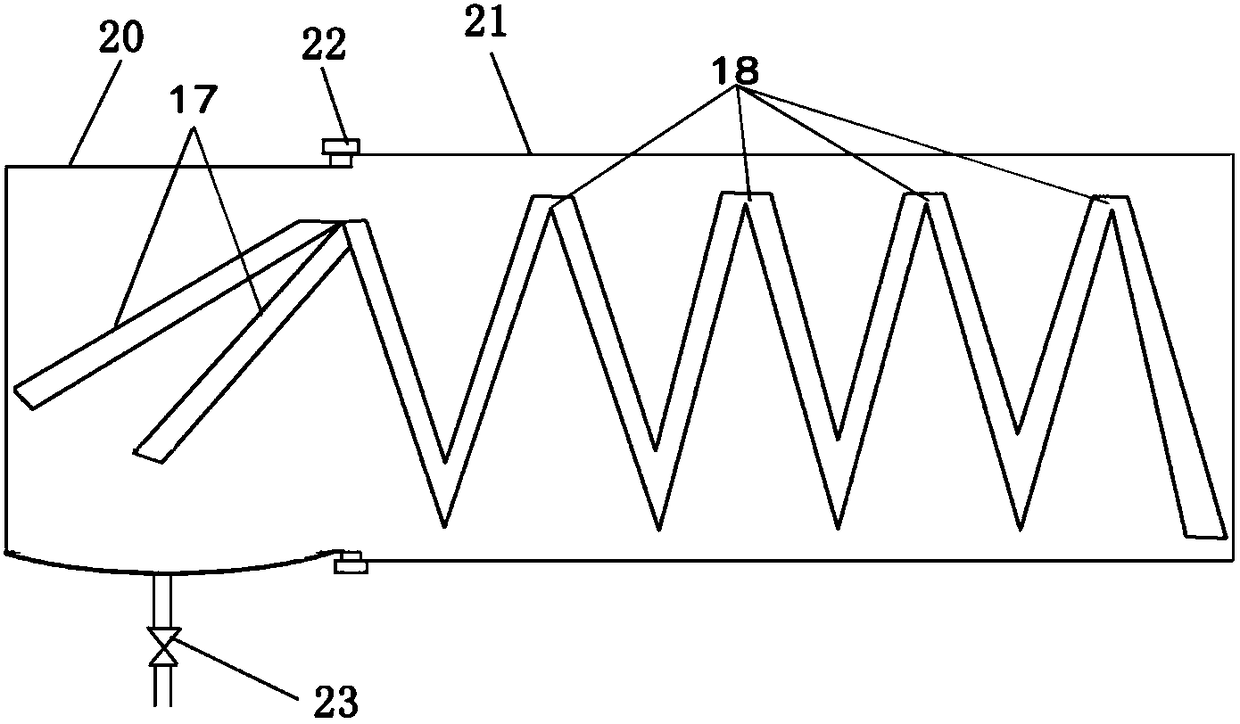

[0022] Such as figure 2 As shown, the engine energy recovery device is used to recover the energy of the exhaust gas of the engine 2, which inc...

Embodiment 2

[0032] Such as figure 1 A kind of garbage conveying device shown, comprises car body 28, garbage hopper 24, first mechanical arm 25, second mechanical arm 26, hydraulic rod 27 and engine system, described car body 28, first mechanical arm 25, the first mechanical arm The two mechanical arms 26 and the garbage bucket 24 are sequentially hingedly connected; a plurality of said hydraulic rods 27 are successively installed between the vehicle body 28 and the first mechanical arm 25, between the first mechanical arm 25 and the second mechanical arm 26, and between the second mechanical arm 25 and the second mechanical arm 26. Between the mechanical arm 26 and the garbage bucket 24 is used to drive the first mechanical arm 25 , the second mechanical arm 26 and the garbage bucket 24 to move; the vehicle body 28 is driven by the engine 2 .

[0033] Such as figure 2As shown, the engine energy recovery device is used to recover the energy of the engine exhaust, which includes a radiat...

Embodiment 3

[0043] Such as figure 1 A kind of garbage conveying device shown, comprises car body 28, garbage hopper 24, first mechanical arm 25, second mechanical arm 26, hydraulic rod 27 and engine system, described car body 28, first mechanical arm 25, the first mechanical arm The two mechanical arms 26 and the garbage bucket 24 are sequentially hingedly connected; a plurality of said hydraulic rods 27 are successively installed between the vehicle body 28 and the first mechanical arm 25, between the first mechanical arm 25 and the second mechanical arm 26, and between the second mechanical arm 25 and the second mechanical arm 26. Between the mechanical arm 26 and the garbage bucket 24 is used to drive the first mechanical arm 25 , the second mechanical arm 26 and the garbage bucket 24 to move; the vehicle body 28 is driven by the engine 2 .

[0044] Such as figure 2 As shown, the engine energy recovery device is used to recover the energy of the engine exhaust, which includes a radiato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com