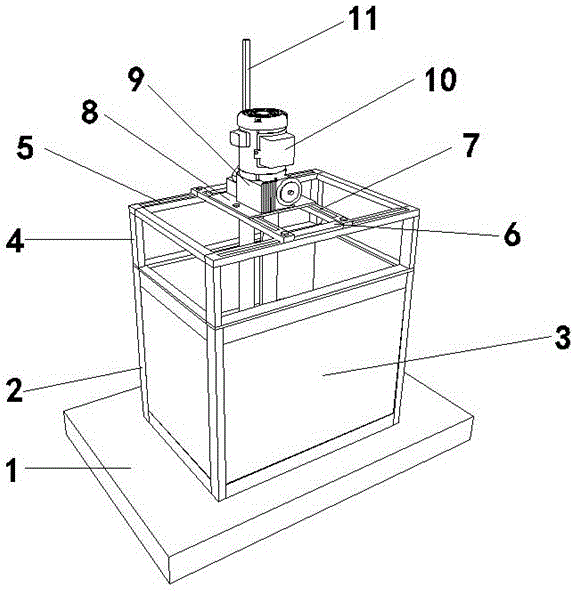

Centrifuge test forced tamping simulation auxiliary test device

A test device, centrifuge technology, applied in the direction of measuring devices, instruments, etc., can solve the problems affecting the reliability of water and soil pressure load tests, different stress levels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

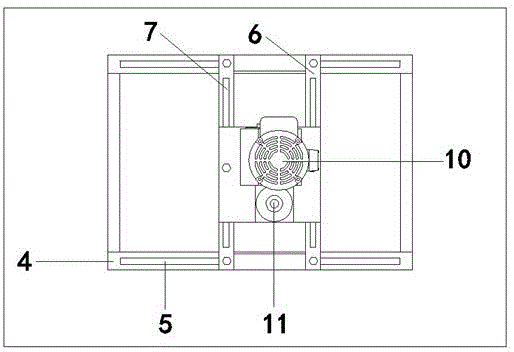

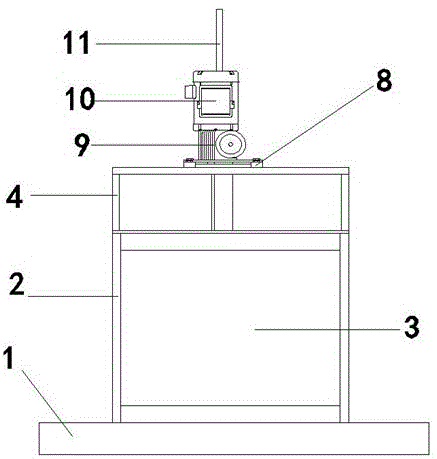

[0025] Such as Figure 1-Figure 6 As shown, the base 1 can be made of ordinary concrete blocks, and it is used as a platform for temporary storage when making soil samples in the model box. The base 1 needs to be level. The tamping manipulator is hoisted to the centrifuge basket for installation and fixation. The model box is composed of a steel frame 2 and a transparent glass observation window 3, the steel frame 2 is a cubic frame, and at least one transparent glass observation window 3 is set on the four sides of the steel frame 2; the external size of the model box 1 is 600mm×400mm×500mm ( length x width x height). In order to reduce deformation under high stress, the steel frame is made of high carbon steel, and the glass is made of thickened tempered glass. According to the bolt hole position of the centrifuge basket, set screw holes at the corresponding positions at the bottom of the model box. In order to closely combine the model box with the dynamic tamping simula...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap