Dynamic characteristic testing system with high confining pressure and temperature control for materials

A dynamic characteristic and testing system technology, applied in the direction of analyzing materials, strength characteristics, measuring devices, etc., can solve problems such as dynamic testing of mineral or rock materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

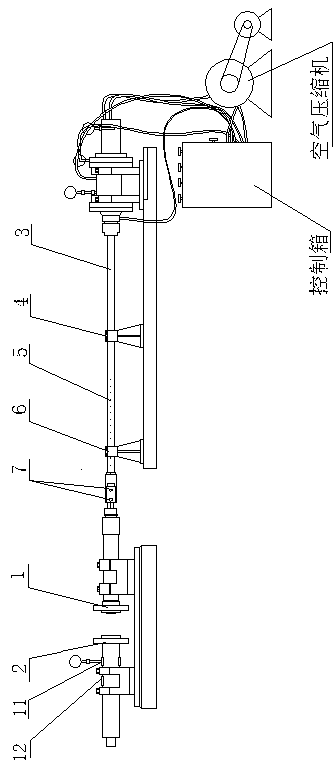

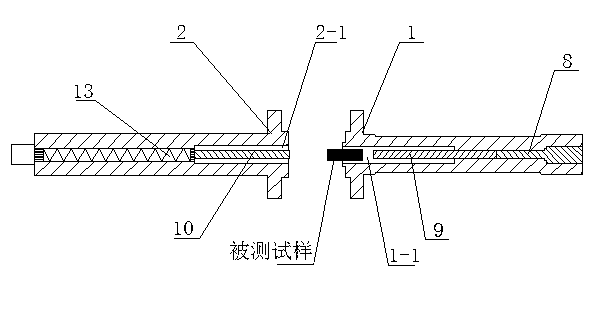

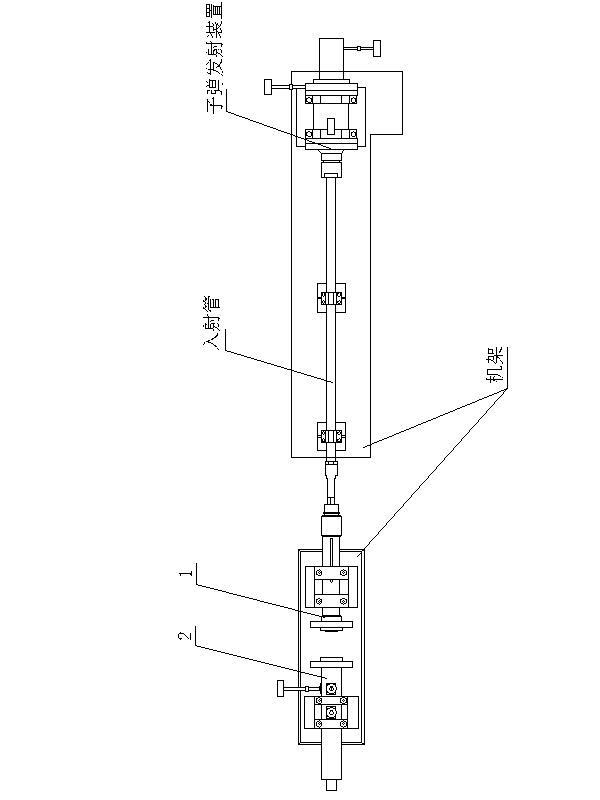

[0012] A high confining pressure temperature-controlled dynamic characteristic testing system for materials, including a sample holding device I 1 and a sample holding device II 2 that cooperate with each other, the sample holding device I 1 has an inner cylinder I 1-1, The sample holding device II 2 has an inner cylinder II 2-1. In this embodiment, the inner cylinder I 1-1 and the inner cylinder II 2-1 are cylindrical cylinders with one end open, and their axes are respectively the sample holding device I 1 and the sample holding device The axis of II 2. The axis centers of the inner cylinder I 1-1 and the inner cylinder II 2-1 coincide and the openings face each other. When the sample holding device I 1 is close to the sample holding device II 2, the inner cylinder I 1-1 and the inner cylinder II 2-1 are buckled together to form a closed container for containing the tested sample. the accommodation chamber. Preferably, the test sample used in the test is made into a cylin...

Embodiment 2

[0022] Coal rocks were tested using the device disclosed in Example 1.

[0023] In this embodiment, a coal rock with a diameter of 50mmx and a length of 50mm is used as the test sample, and the test sample is simulated to be in the state of 120 meters underground to obtain constitutive properties such as high strain rate strength, fracture characteristics and stress-strain relationship. Include the following steps:

[0024] 1) Adjust the axial feed device so that the sample holding device I 1 is separated from the sample holding device II 2. See attached figure 2 , Install the prepared test sample inside the inner cylinder I 1-1.

[0025] 2) Adjust the axial feed device so that the sample holding device I 1 and the sample holding device II 2 are combined together. That is, the inner cylinder I 1-1 and the inner cylinder II 2-1 are snapped together to form a chamber for containing the tested sample. The sample to be tested is enclosed in the accommodating cavity, and its t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap