A hanger hook fixture

A technology of clothes hangers and fixtures, which is applied in the direction of hand-held tools, manufacturing tools, and workpiece clamping devices. Economic benefits, precise positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

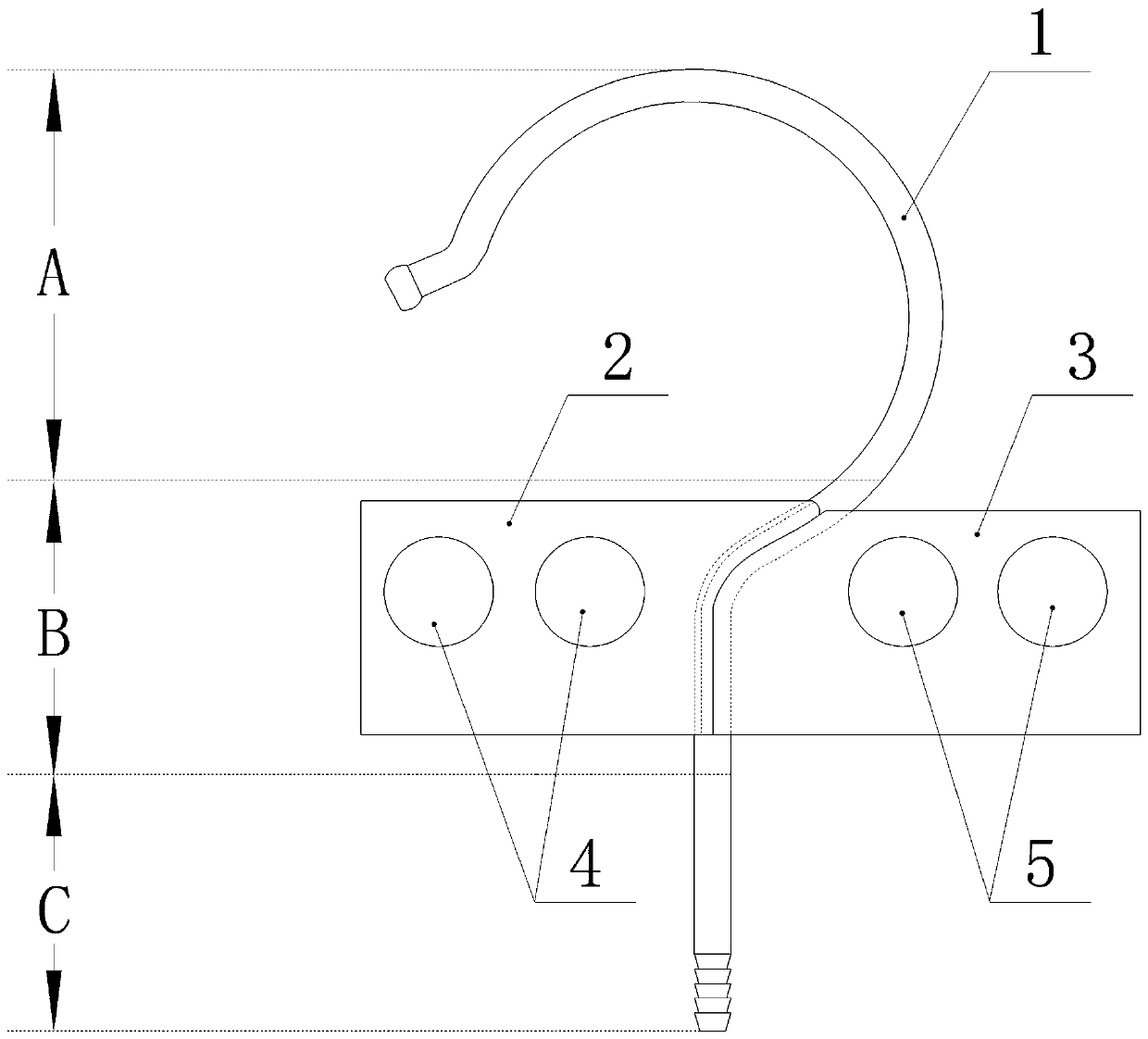

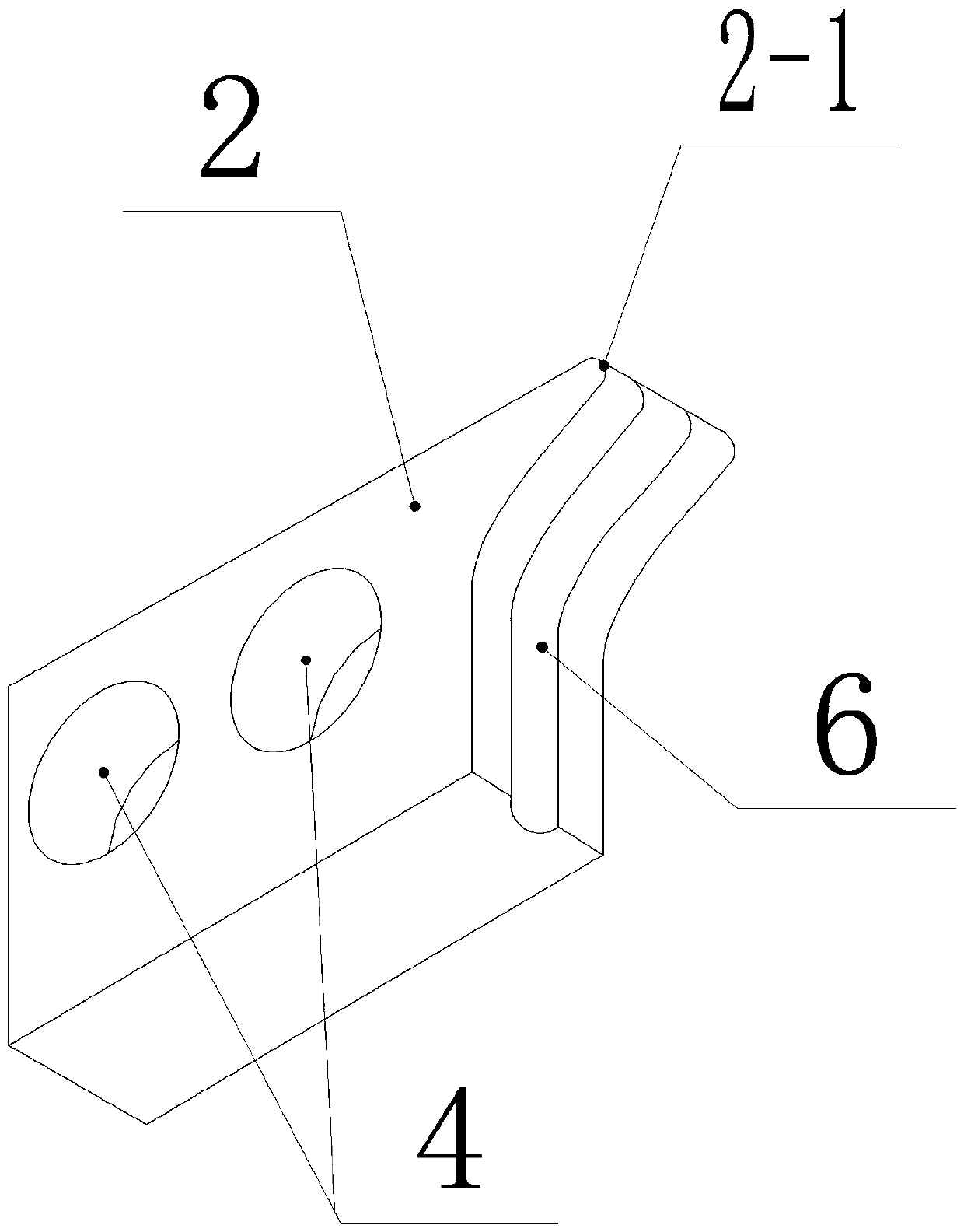

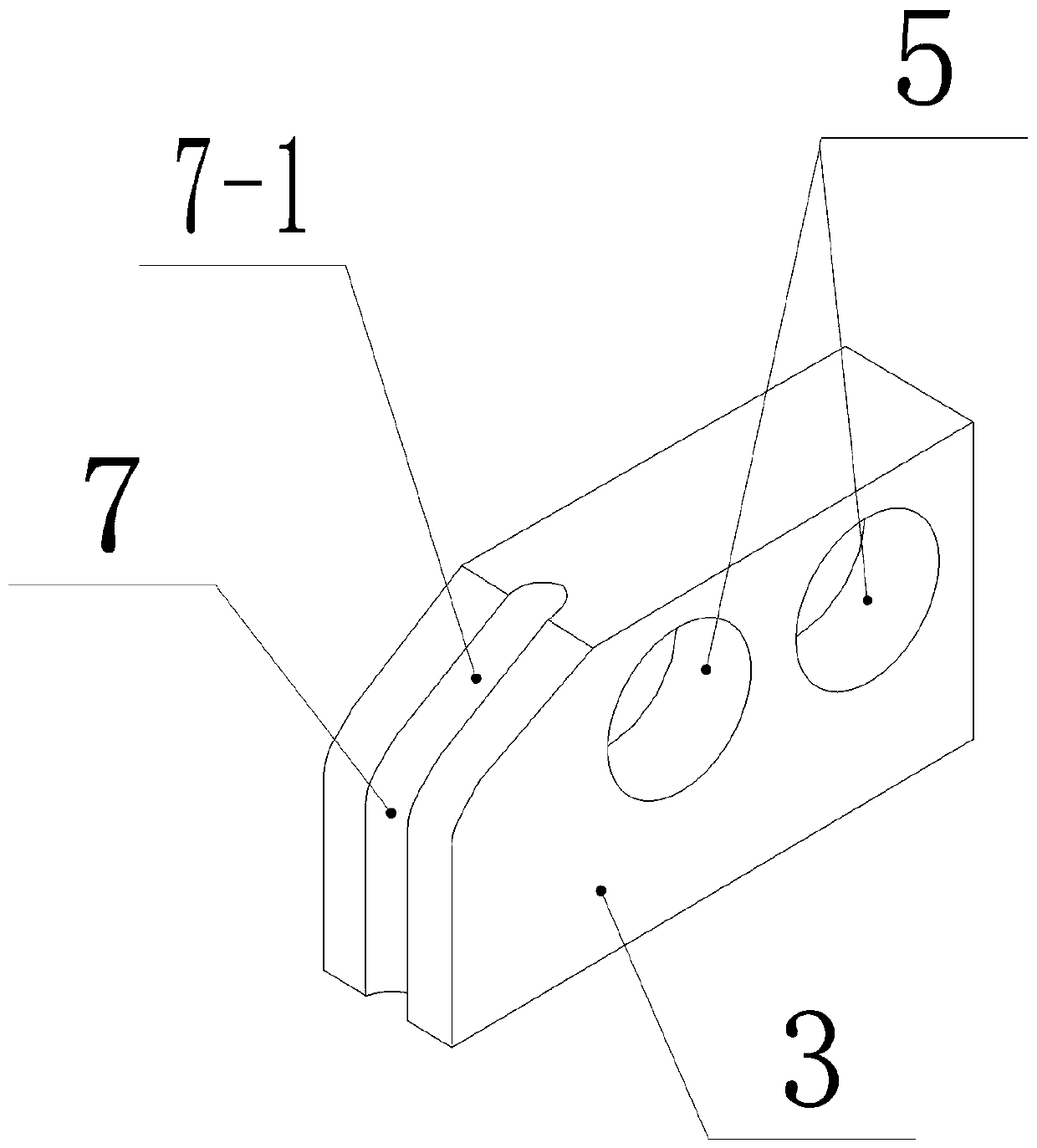

[0028] Such as Figure 1-Figure 3 As shown, a clothes hanger hook clamp includes a clamping block, and the clamping block includes a left clamping block 2 and a right clamping block 3, wherein,

[0029] The right end surface of the left clamping block 2 is adapted to the arc and bending angle of the clamping area B of the hanger hook 1, and the right end surface is provided with a first clamping groove 6, and the first clamping groove 6 is in line with the circle of the clamping area B of the hanger hook 1. The arc and bending angle match;

[0030] The left end surface of the right clamping block 3 is adapted to the arc and bending angle of the clamping area B of the hanger hook 1, and the left end surface is provided with a second clamping groove 7, and the second clamping groove 7 is in line with the circle of the clamping area B of the hanger hook 1. The arc and bending angle match;

[0031] When the right end surface of the left clamping block 2 is attached to the left e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com