Bucket lid correcting and opening device

A cap opener and barrel cap technology, which is applied in the disassembly of flanged bottle caps and flanged caps, can solve the problems of single cap opening, inconvenient operation, and inconspicuous efficacy, so as to avoid lax sealing and reduce labor costs. The effect of increasing strength and increasing the opening area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

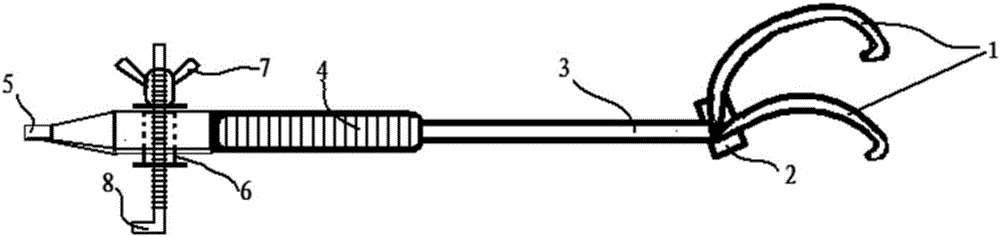

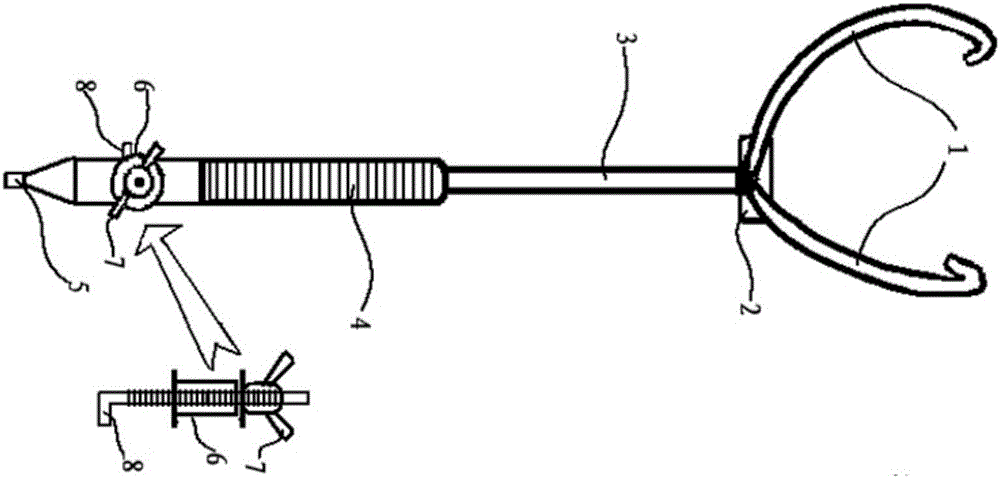

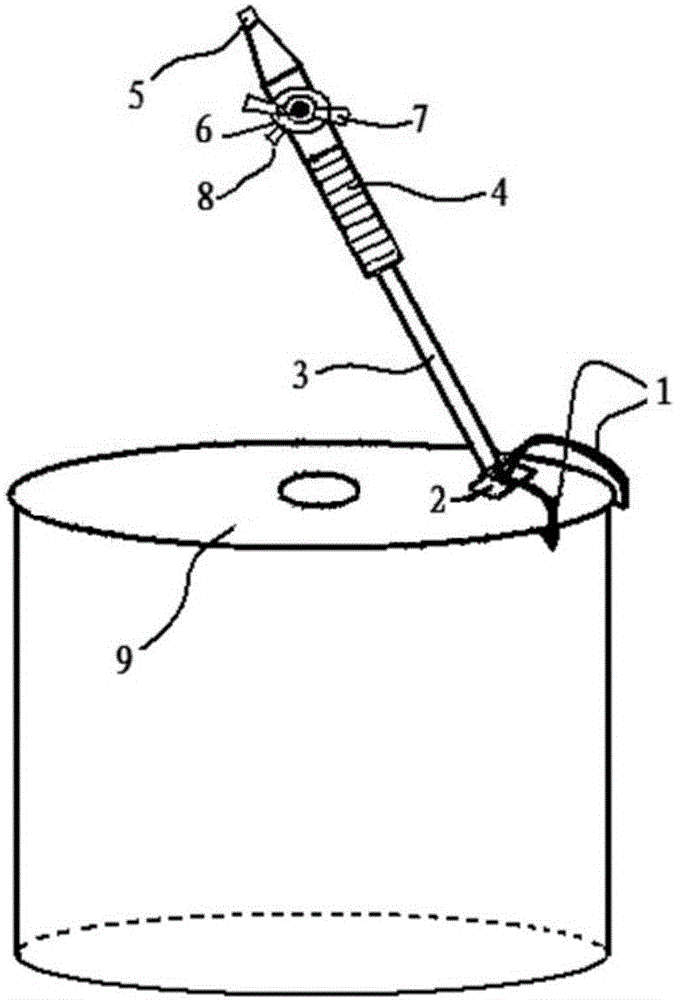

[0021] Such as Figure 1-4 As shown, the present invention can be used for the opening of iron barrels and plastic barrels and the correcting tooling for capping back. When sampling and testing barreled items, opening the lid before use, and sealing the lid back after use, the straightening and lid opening device can realize quick opening, and realize compression and straightening after the lid is returned.

[0022] According to the present invention, two half-arc claw heads 1 with hook heads are installed on the head of a long cylindrical pole 3, and the two claw heads 1 form an included angle of 15-90 degrees to increase the width of the opening. At the joint between the pole 3 and the claw head 1, add a rectangular flat plate 2 (four corners can be chamfered) to serve as the force-bearing surface of the pole 3 when the cover is opened. The strut 3 forms an included angle of 60-120 degrees with the force-receiving surface, so as to form a leverage force, and it is more labo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com