A composite silicate p.c32.5r cement and its application in decoration

A composite silicate and cement technology, which is applied in cement production, construction, building construction, etc., can solve the problems of easy drying of cement mortar, difficulty in plastering, and difficulty in marketing, so as to achieve good strength and standard consistency, and guarantee the market The effect of improving market share and customer satisfaction

Active Publication Date: 2018-07-20

CHINA RESOURCES CEMENT TECH RES DEV

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Composite Portland cement using these two materials as admixtures requires a lot of water, especially when the ratio of the two is above 10%, the cement mortar is easy to dry, the fluidity of the mortar is low (generally about 180mm), and the mortar flows Poor performance, insufficient paste head and viscosity, insufficient fineness and smoothness of the paste, difficult to smooth the mortar, difficult to plaster, and difficult to plaster, especially the construction workers of large-scale commercial and civil building decoration projects are very reluctant to use this kind of cement. Difficulties in market sales also affect the release of production capacity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

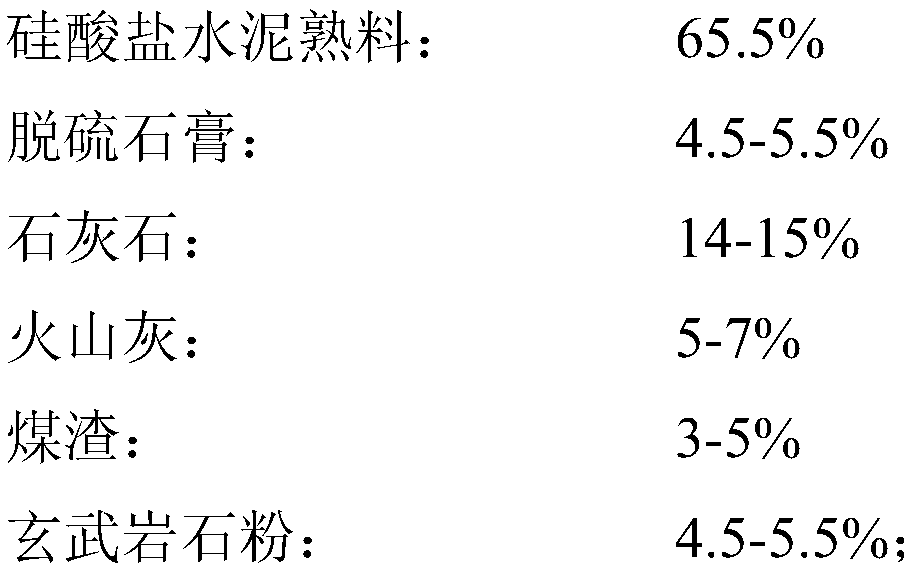

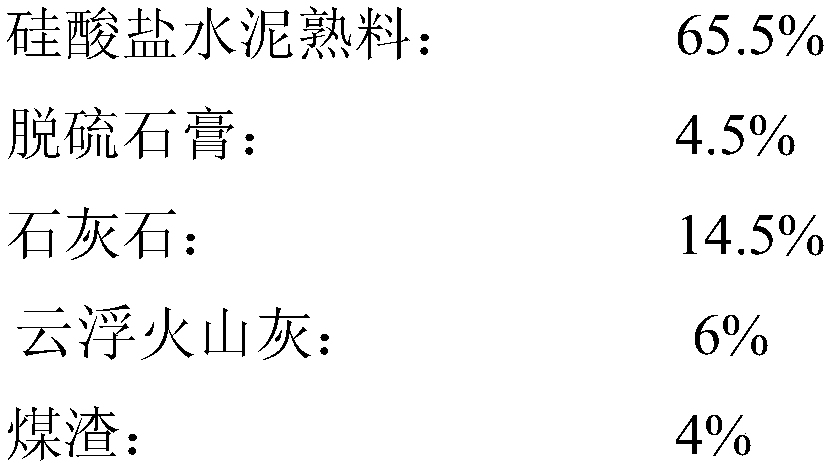

[0034] A kind of composite portland P.C32.5R cement, is prepared by the raw material of following percentage by weight:

[0035]

[0036]

[0037] Then add Grace MCC599 grinding aid with 0.05% cement quality.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses composite silicate P.C32.5R cement and application thereof in decoration. According to the formula, the cement disclosed by the invention adopts a Grace delayed coagulation type MCC599 grinding aid as well as basalt powder and Yunfu volcanic ash to replace slag, so that the effect of prolonging the cement coagulation time is remarkable, cement slurry is soft, smooth in surface and good in water-retaining property, the requirements of the decoration market on plastering, rendering and tile fixing can be met, the customer satisfaction degree can be increased, and the sale volume can be greatly increased. The coagulation time can be prolonged, meanwhile the cement is relatively good in strength and normal consistency, and the unit production time is generally identical to that of conventional cement.

Description

technical field [0001] The invention belongs to the field of building materials, and in particular relates to a composite silicate P.C32.5R cement and its application in decoration. The cement can replace decoration cement and meet the requirements for tile tiling, interior and exterior wall plastering, and the like. Background technique [0002] The common formula of the existing composite Portland P.C32.5R cement for decoration is: 65.5% clinker, 4.5% desulfurized gypsum, 14.5% limestone, 5.5% slag, 10.0% wet coal cinder, and the quality of external cement is 0.025% % of Horizon's production of grinding aids. [0003] In the above formula, coal cinder and slag are both porous alkaline substances with strong water absorption. Composite Portland cement using these two materials as admixtures requires a lot of water, especially when the ratio of the two is above 10%, the cement mortar is easy to dry, the fluidity of the mortar is low (generally about 180mm), and the mortar f...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B7/28C04B28/04E04F13/02

CPCC04B7/28C04B28/04C04B40/0039E04F13/02C04B24/122C04B7/04C04B7/12C04B2103/52C04B14/06C04B14/04Y02P40/10

Inventor 袁昌成

Owner CHINA RESOURCES CEMENT TECH RES DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com