Manufacturing method for wavelength conversion device

A technology of wavelength conversion device and wavelength conversion layer, which is applied to components of lighting devices, lighting devices, lighting and heating equipment, etc., can solve problems such as high equipment requirements, complicated procedures, and unsuitable production, so as to prevent adverse effects and improve Reliability, the effect of reducing the time at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

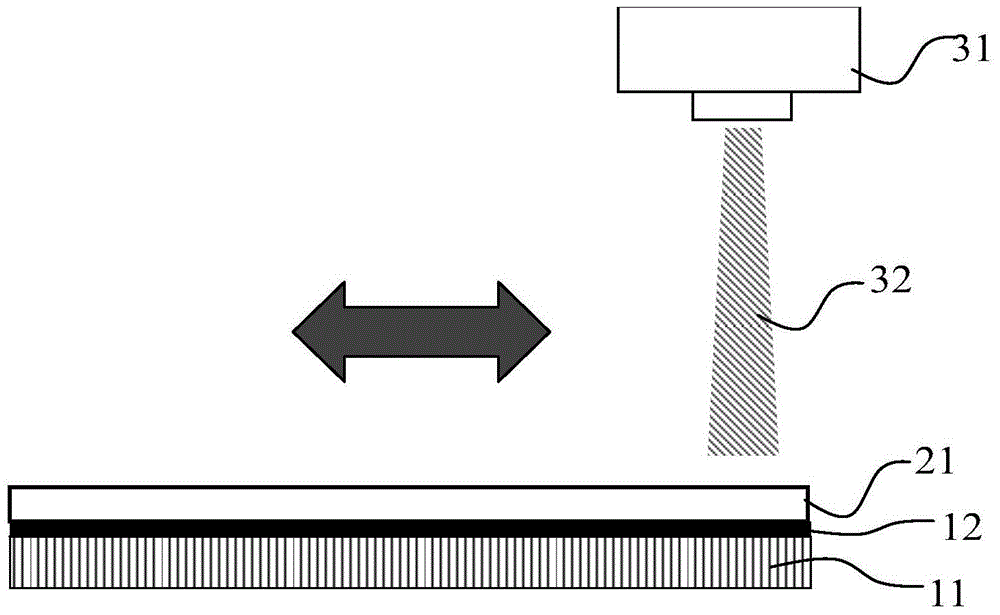

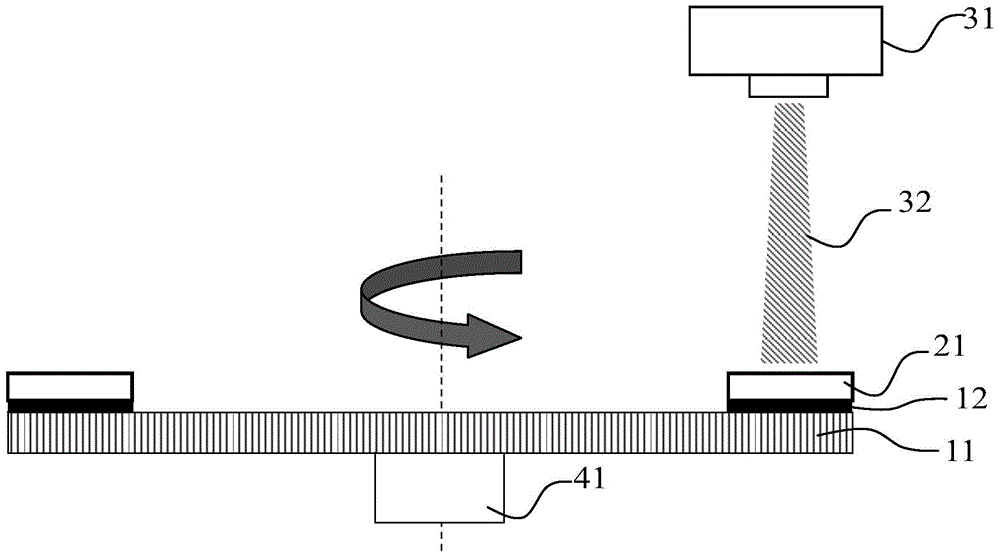

[0024] As mentioned in the background technology section, the manufacturing method of the wavelength conversion device in the prior art has the defect that the reflective layer of the wavelength conversion device cannot withstand high temperature, resulting in low reliability of the wavelength conversion device. In order to improve the above situation, the present invention provides A method for preparing a wavelength conversion device, the preparation method comprising the following steps: providing a thermally conductive substrate prepared with a reflective layer; mixing phosphor powder and a transparent inorganic adhesive to form a slurry; coating the slurry on the reflective layer of the thermally conductive substrate above, forming a wavelength conversion layer green sheet; using a laser to sinter the wavelength conversion layer green sheet to obtain a wavelength conversion device.

[0025] In the above-mentioned preparation method of the present invention, the mixed slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap