Collar pressing machine with counting function

A collar pressing machine and functional technology, applied in clothing, clothing, applications, etc., can solve the problems of disordered collar sorting, and achieve the effect of solving the sorting disorder, accurate and orderly arrangement, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

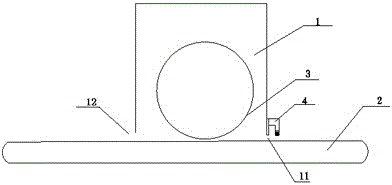

[0007] Such as figure 1 As shown, the present invention provides a collar crimping machine with a counting function, comprising a case 1, a crimping roller 3 located in the case 1, and a conveyor belt 2 located at the lower end of the case 1 and closely attached to the crimping roller 3. The two sides of 1 are respectively provided with an entrance 11 and an exit 12 through which the conveyor belt 2 passes, and a counter 4 is provided above the entrance 11 .

[0008] The collar is placed on the conveyor belt 2, and the counter 4 has a sensing function, which can print and paste numbers on each collar before the collar enters the chassis 1. When it is found that the collar needs to be pressed twice, the counter 4 is turned off, and the collar enters the cabinet 1. Start the counter 4 immediately behind the cabinet 1, and after the collar roller 3 carries out the secondary collar collar, the operator places the collar in an accurate position according to the original number on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com