Take-up reel of micro-adjustable wire drawing machine

A technology of wire take-up reel and wire drawing machine, which is applied in the field of fine-tuning wire drawing machine take-up reel, can solve the problem of wire winding accumulation and achieve the effect of avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

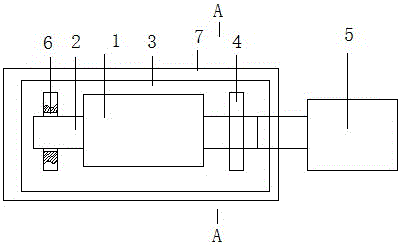

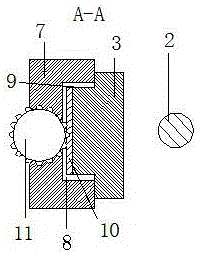

[0015] The take-up reel of the fine-tuning wire drawing machine of the present invention includes a take-up roller 1 and a roller 2 for the take-up roller 1 to pass through. The interference fit is on the roller 2, and the initial position of the roller 2 is opposite to the tension roller, and the roller 2 is provided with a driving device that drives the roller 2 to reciprocate along the axial direction of the roller 2. The driving device is arranged on the working platform 7, and the working platform 7 is provided with a guide groove 8 for partially inserting the driving device. The bottom surface is a rack 10 , and a gear 11 cooperating with the rack 10 is arranged in the guide groove 8 . By adopting the above structure, the driving device is used to drive the roller 2 to realize reciprocating motion, so that the thin wires are evenly distributed along the axis of the roller 2, and the traditional accumulation is avoided. A guide groove and a guide protrusion are set betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com