A turntable bottle cap flanging device with a gradual guide groove

A turntable type bottle cap technology, which is applied in the field of turntable type bottle cap flanging device, can solve the problems of low processing efficiency and achieve the effects of convenient operation, improved work efficiency and reduced intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

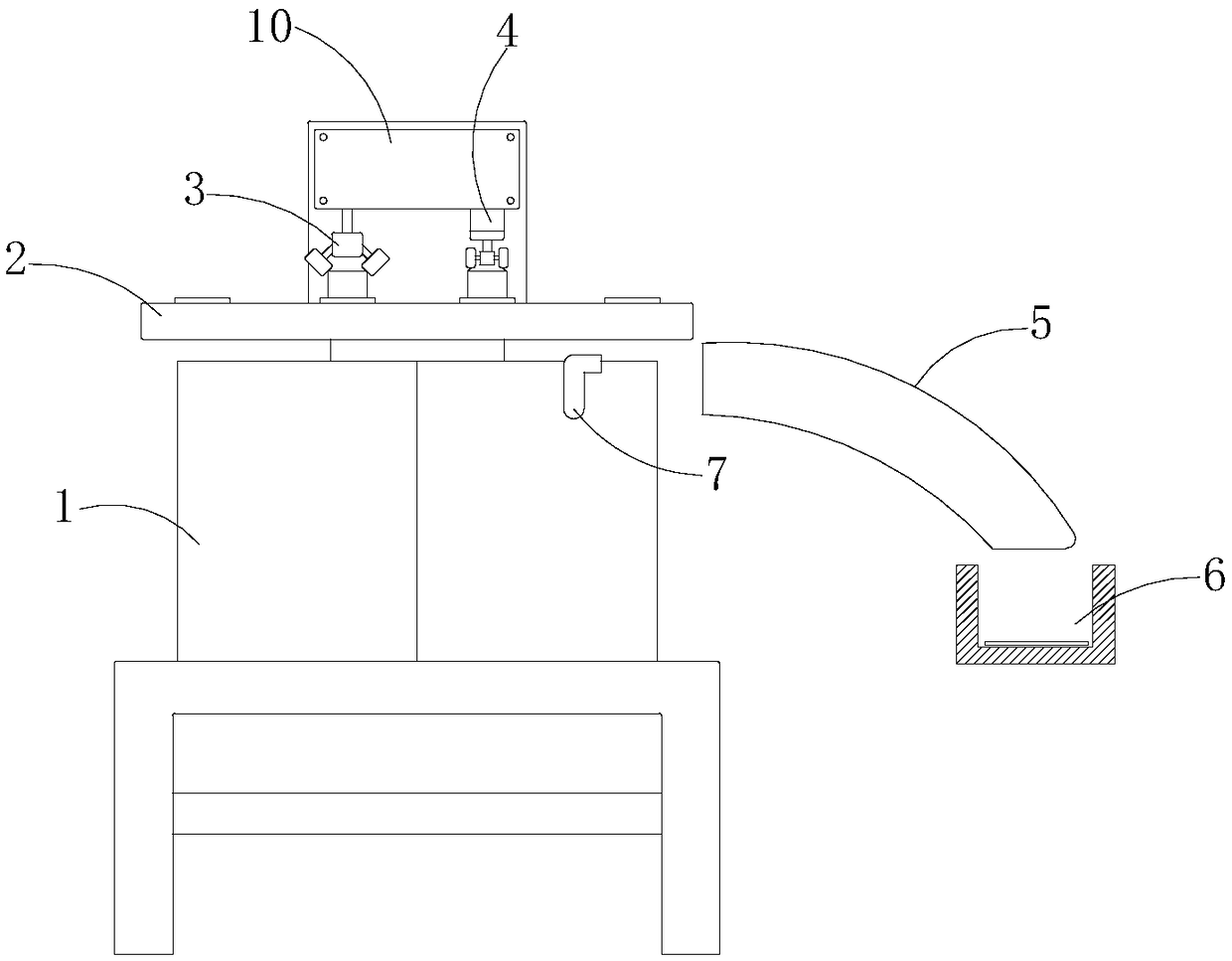

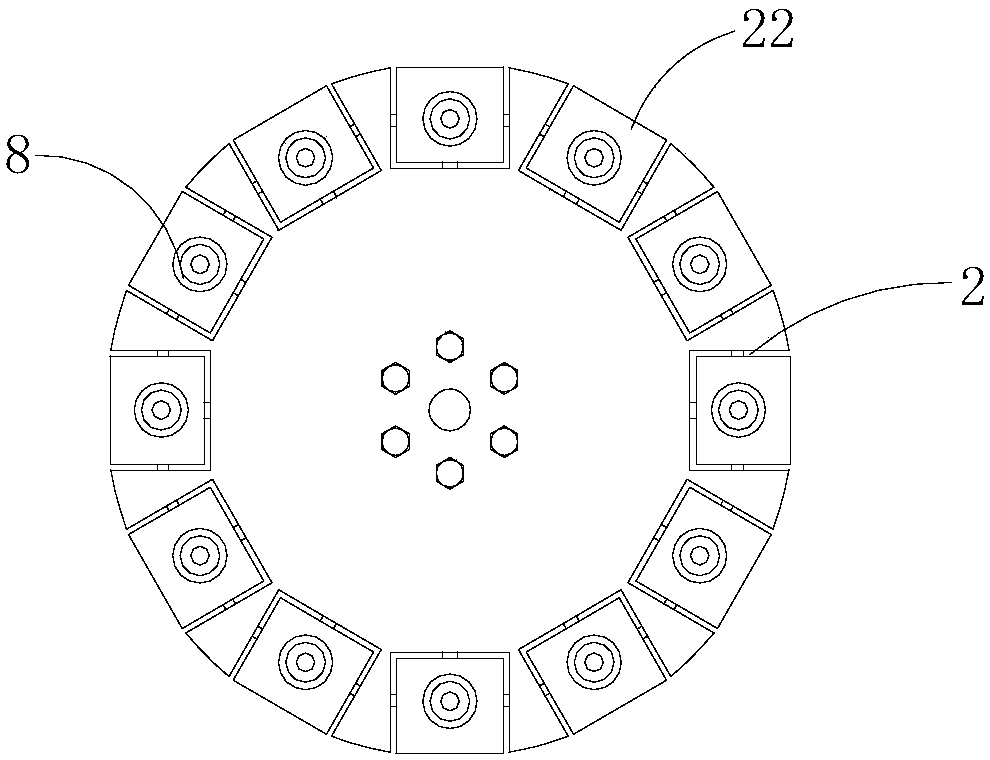

[0034] Such as figure 1 and figure 2 As shown, a turntable bottle cap flanging device with a gradual guide groove includes a base 1 and a turntable 2 that is rotatably fitted on the base 1; the edge of the turntable 2 is connected with several turning plates 22 arranged in a ring, each The fixture 8 that places bottle cap usefulness is installed in the block turnover plate 22.

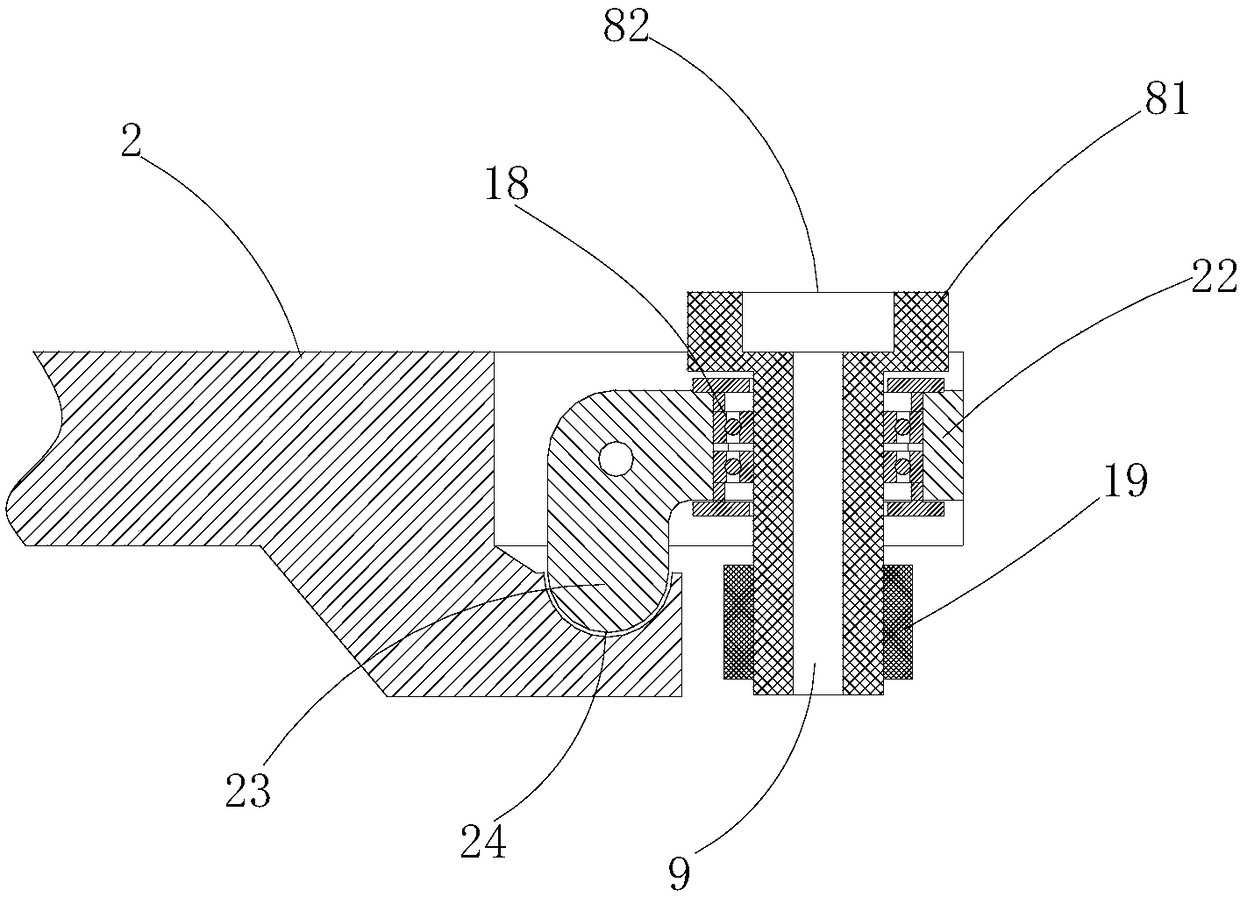

[0035] Such as image 3 and Figure 4 As shown, the surrounding positions of the turntable 2 are successively divided into a loading station, a folding station, a blanking station and a blanking station. The turntable 2 is provided with a guide rail groove 24 , and the turning plate 22 has a guide portion 23 sliding along the guide rail groove 24 .

[0036] The jig 8 has a jig body 81 that is movably inserted into the turntable 2. The top of the jig body 81 is an accommodating groove 82 for placing bottle caps. The interior is provided with an axially penetrating ventilation hole 9, and a friction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com