Precise mechanical workpiece punching equipment driven by electromagnetism

A technology of electromagnetic driving and punching equipment, applied in the field of punching machines, can solve the problem of high drilling error rate and high drill bit damage rate, and achieve the effects of improving practicability and functionality, improving collection efficiency, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

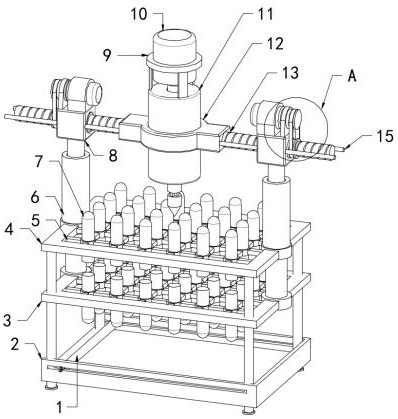

[0040] refer to Figure 1-7 , a precision mechanical workpiece punching device driven by electromagnetic force, including a top frame 4, two middle frames 3 and a bottom compartment 2 arranged sequentially at the bottom of the top frame 4, and two symmetrically arranged on both sides of the top of the top frame 4 The oil cylinder 6 and the bearing tube 11 vertically arranged at the top center of the top frame 4;

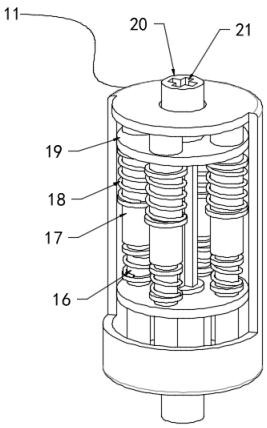

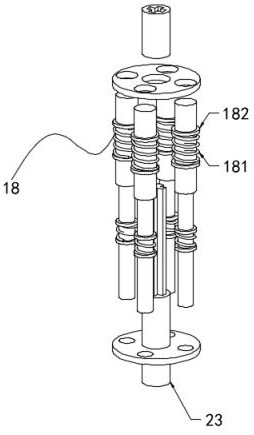

[0041] The top and bottom of the inner chamber of the carrying cylinder 11 are horizontally provided with built-in moving plates 19, and the bottom of the top built-in moving plates 19 is arranged in an annular array along the circumferential direction of the carrying cylinder 11. The sleeve 17 fixedly connected to the top of the inner cavity of the bearing cylinder 11, the top of the built-in moving plate 19 at the bottom is arranged in an annular array along the circumferential direction of the bearing cylinder 11. The bottom of the chamber is fixedly connected wi...

Embodiment 2

[0051] refer to Figure 1-7 , transmission structure 1 includes cross rod 1 241, transmission structure 2 includes cross rod 2 242, transmission structure 3 includes cross rod 3 243, one end of the output shaft of motor 10 is fixedly connected with the end of cross rod 1 241, and the drill bit One end of the butt joint rod 23 close to the connecting shaft 20 is fixedly connected to the end of the cross rod two 242, and the end of the drill bit near the drill bit docking rod 23 is fixedly connected to the end of the cross rod three 243. And the cross groove 21 that is compatible with the cross rod one 241 and the cross rod two 242, the end of the drill bit docking rod 23 near the drill bit is provided with the cross groove 21 that is compatible with the cross rod three 243, and the cross rod three 243 on the top of the drill bit One end of the drill bit is fixedly connected with a magnet piece, and the top of the inner cavity of the cross groove 21 at the end of the drill bit d...

Embodiment 3

[0053] refer to Figure 1-7 , one end of the collection rod 1 is connected with a moving column 27 through a rectangular rod 22, and one end of the moving column 27 is fixedly connected with a pull ring 28, and the other end of the collecting rod 1 is connected with a rectangular rod 22 through a moving column 27, and the rectangular rod 22 One end is fixedly connected with a pull ring 28, and the two side walls of the bottom bin 2 are provided with a rectangular groove 29 compatible with the rectangular rod 22, and a slope is provided on one side of the collecting rod 1. Specifically, it can be known from the above embodiments: The cooperation of collecting rod 1, rectangular rod 22, moving column 27 and pull ring 28, pulling pull ring 28 drives collecting rod 1 to move left and right, when two moving columns 27 are positioned in rectangular groove 29, collecting rod 1 can rotate, make The slope corresponds to the bottom of the inner cavity of the bottom bin 2, so that the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com