Flat light installation mechanism

An installation mechanism and a technology for flat lamps, which are applied in the direction of connecting components, mechanical equipment, lighting devices, etc., can solve the problems of wasted labor, labor hours, and inconvenient factory practices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: This embodiment is the best embodiment of the present invention. A flat light installation mechanism, such as Figure 4 to Figure 6 As shown, it is composed of a screw 1 and a hook hanger 2. There are two installation mechanisms and are arranged symmetrically at the back edge of the flat lamp. When the flat light leaves the factory, the screw 1 is screwed on the back A of the flat light, and the hook hanging member 2 is independent of the flat light, such as Figure 4 Shown.

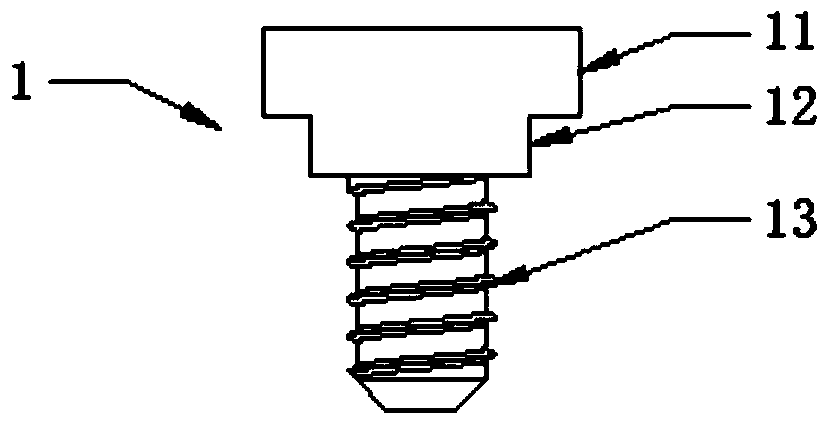

[0029] Such as figure 1 As shown, the screw 1 is integrally composed of a screw head 11, a clamping section 12, and a thread section 13. The clamping section 12 is integrally connected between the screw head 11 and the thread section 13, and the clamping section The diameter of 12 is smaller than the diameter of the screw head 11 and larger than the diameter of the thread segment 13. The screw head 11 is cylindrical, and the clip 12 is cylindrical.

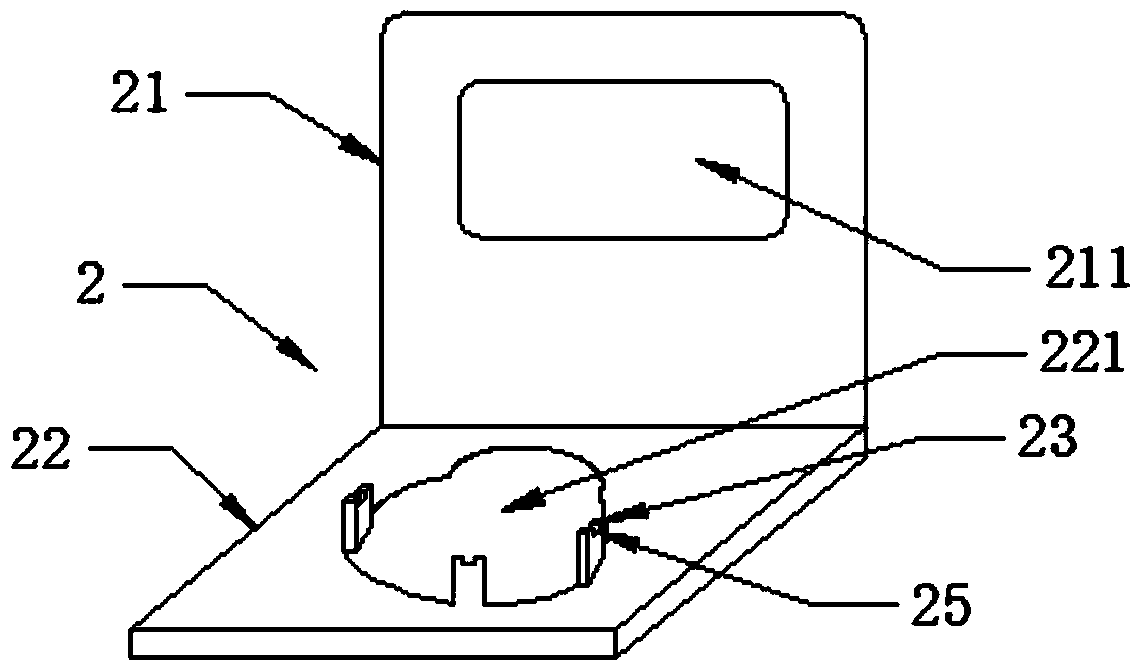

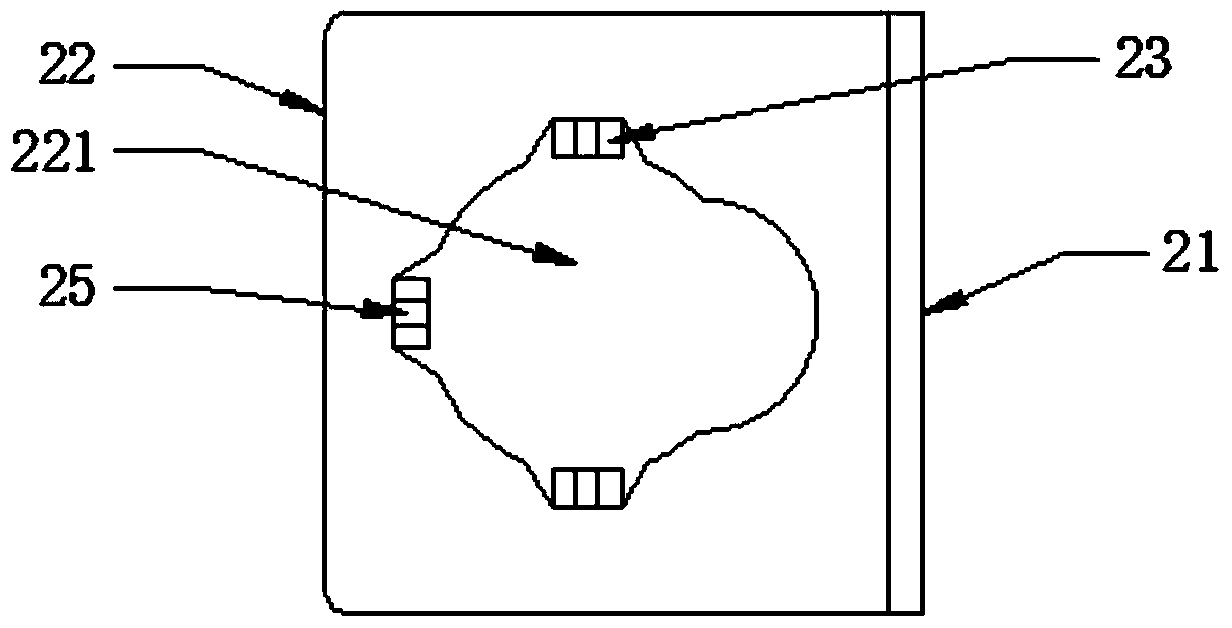

[0030] Such as figure 2 with imag...

Embodiment 2

[0033] Embodiment 2: The installation mechanism of this embodiment is substantially the same as that of Embodiment 1. This embodiment is a modification of Embodiment 1, and only the structure of the protection block is different. The protection block 24 in the installation mechanism of this embodiment, such as Figure 7 with Figure 8 As shown, it is a bendable strip member integrally connected to the junction of the large screw hole and the small screw hole. When the protection block 24 is perpendicular to the screw hole plate 22, the clip 12 of the screw 1 can move from the large screw hole of the hook hanger to the small screw hole, such as Figure 7 As shown; when the protection block 24 is bent to be in the same plane as the screw hole plate 22, the protection block 24 prevents the clamping section 12 of the screw 1 from moving from a small screw hole to a large screw hole, such as Figure 8 Shown.

Embodiment 3

[0034] Embodiment 3: The installation mechanism of this embodiment is substantially the same as that of Embodiment 1. This embodiment is a modification of Embodiment 1, except that the structure of the protection block is different. The protection block 3 of the installation mechanism of this embodiment, such as Picture 9 As shown, it is a plastic block, rubber block or silicone block independent of the hook hanger. The protective block 3 can be inserted into the large screw hole of the hook hanger 2 to prevent the screw 1 from being screwed. The head 11 passes through the large screw hole of the hook hanger 2, such as Picture 10 Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com