Methods and systems to determine rotor imbalance

A technology for rotor unbalance and handling subsystems, which is used in static/dynamic balance testing, blade support elements, machine/structural component testing, etc., and can solve problems such as rotor unbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

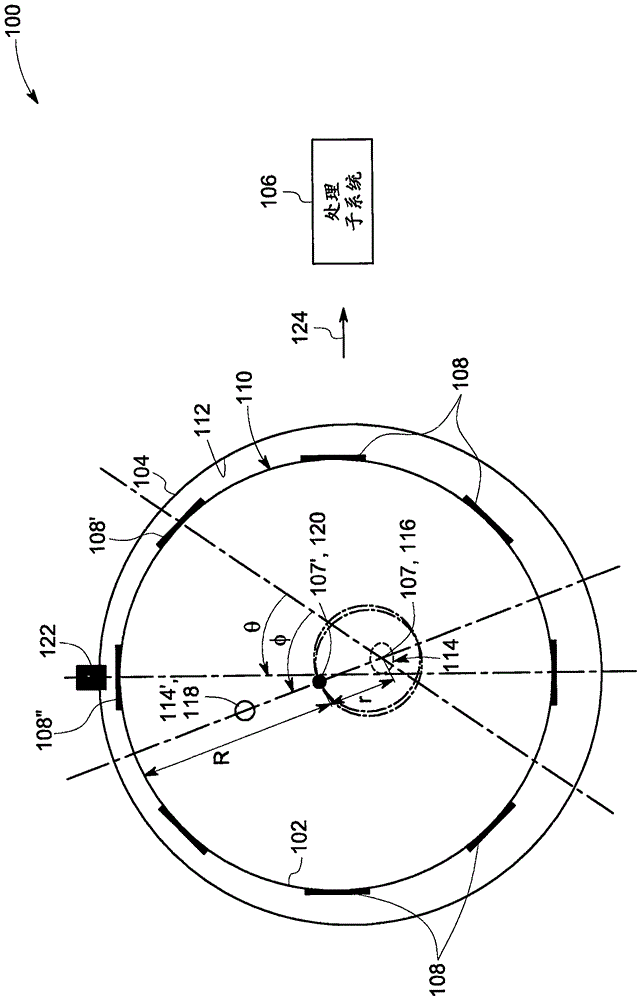

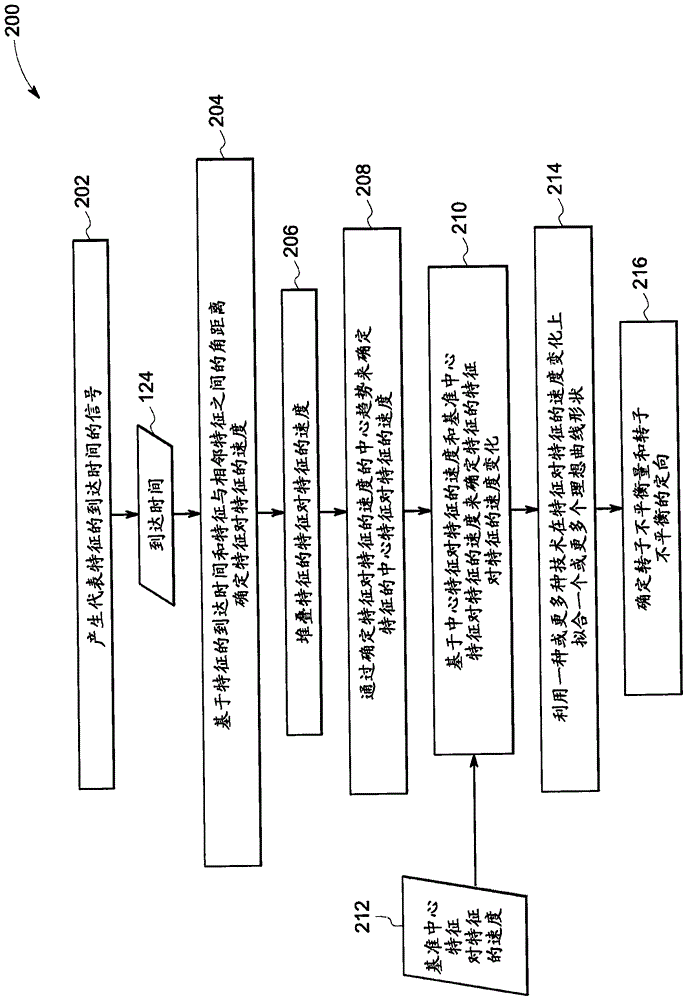

[0031] Rotors in rotating machines may have mass imbalances or load imbalances. For example, a rotor mass imbalance occurs when the center of rotor mass is not on the rotor's axis of rotation. For example, load imbalances may occur due to misfires within the cylinders of an internal combustion engine. The present systems and methods, described in detail below, detect imbalances on the rotor. Additionally, the present systems and methods determine the amount and orientation of the imbalance on the rotor. The present systems and methods determine the presence, amount, and orientation of imbalances based on rotor speed, thus requiring no additional components to be installed. The present systems and methods described herein may be used in a variety of machines, devices, engines, turbines, turbochargers, or the like employing rotors.

[0032] see now figure 1 , shows a block diagram of a system 100 for determining an unbalance on a rotor member 102 (hereinafter "rotor 102") ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com