Backward scattering type infrared silt measurement sensor

A technology for measuring sensors and backscattering, applied in the field of sensors, can solve the problems of not being able to eliminate the influence of sediment particle size factors, affecting the size of scattered light intensity, and being unable to measure the spatial distribution characteristics of scattered light intensity of sediment particles, so as to eliminate The effect of sediment particle size change factors on the influence of sediment measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

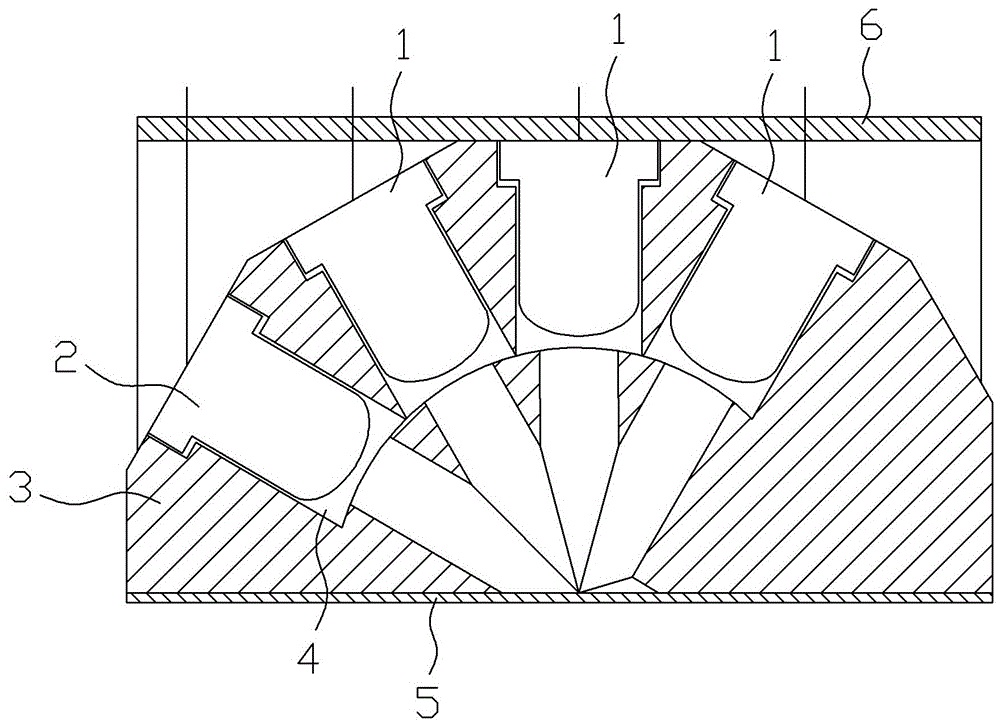

[0007] Such as figure 1 As shown, the backscattering infrared sediment measurement sensor includes a photodetector 1, an infrared light source 2 and an angle positioning block 3 for fixing the photodetector 1 and the infrared light source 2. The direction is provided with at least two described photodetectors 1 that are at different angles with the incident light direction, and is used to receive the infrared light emitted by the sediment solution to be measured at different backscattering angles, according to the scattered light intensity distribution of the sediment solution The average particle size of the sediment solution is calculated in reverse by the feature, and then the mathematical model of the sediment concentration is corrected.

[0008] The angle positioning block 3 is provided with several positioning holes 4 for positioning the angles of the components, and the photodetector 1 and the infrared light source 2 are respectively fixed in the positioning holes 4 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com