Feeding mechanism for bushing forming tools for punching machines

A technology of feeding mechanism and bearing bush, which is applied in manufacturing tools, metal processing equipment, feeding devices, etc., can solve problems such as low work efficiency and hidden dangers of operation safety, so as to improve work efficiency, avoid hidden dangers of safety, and realize automatic feeding of machinery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

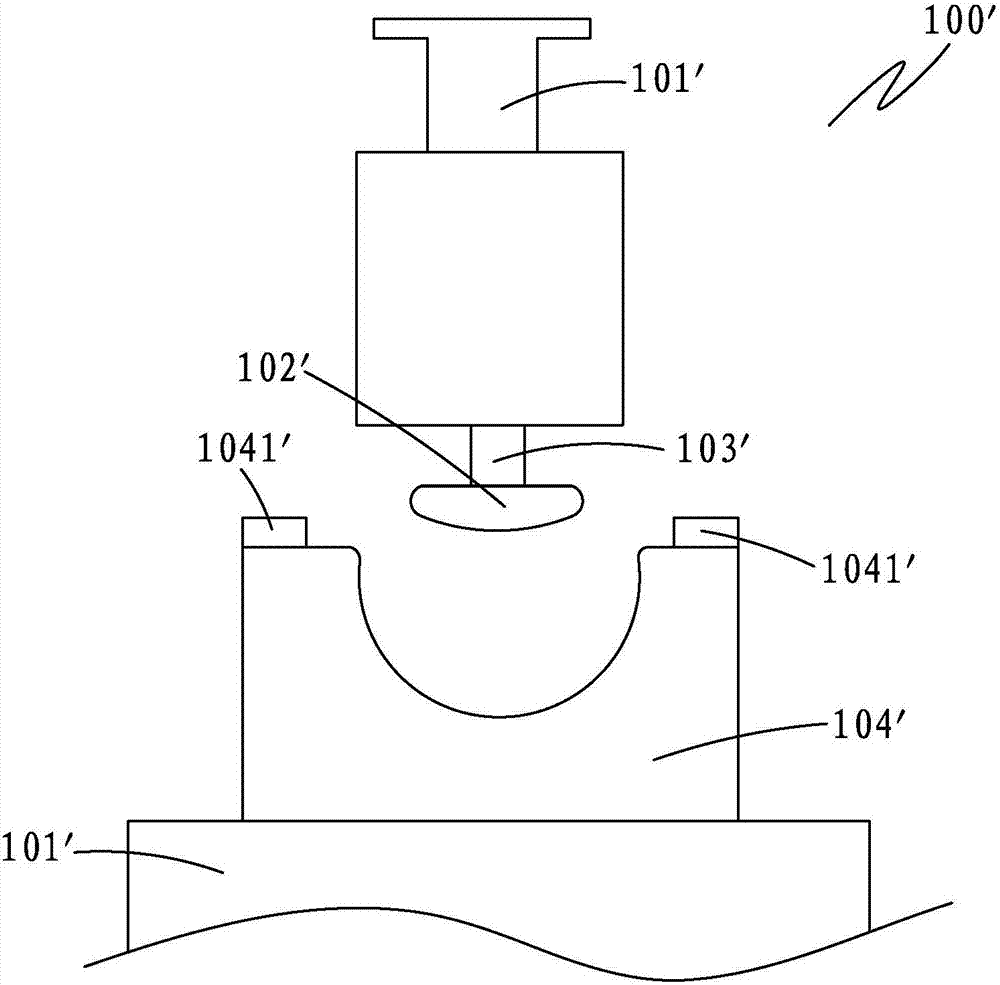

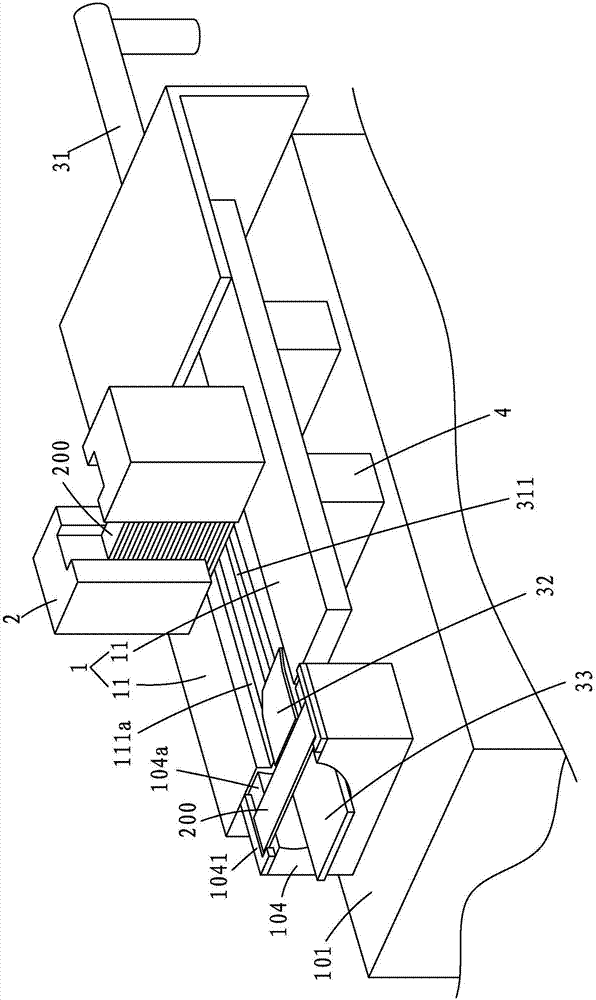

[0022] Please refer to Figure 1 to Figure 8 , the present invention is used for the feeding mechanism of the bearing pad forming tool of the punching machine, that is, a feeding mechanism is added on the basis of the existing bearing pad forming tool, and the feeding mechanism is located on the right side of the circular pressing die 104 of the bearing pad forming tool; and the feeding mechanism includes A slideway 1 , a piece of material bin 2 and a push unit 3 arranged adjacent to the round die 104 , the piece material bin 2 can just accommodate a stack of sheet materials 200 .

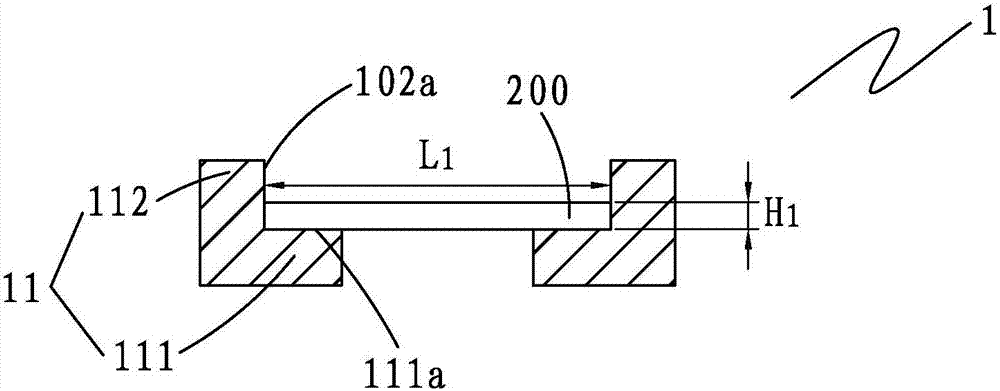

[0023] The slideway 1 is formed by two substrates 11 with L-shaped cross-sections facing each other and spaced apart. The two substrates 11 are set in one-to-one correspondence with the two fixed pressure plates 1041 of the bearing bush forming tool, so that the sheet material 200 falling on the two substrates 11 is under external force. can be pushed between the two fixed platens 1041 along the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com