C-type multi-angle manual self-locking turnover mechanism and application method thereof

A flip mechanism, multi-angle technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of increased cost, large space occupation, and high labor intensity of operators, and achieves the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

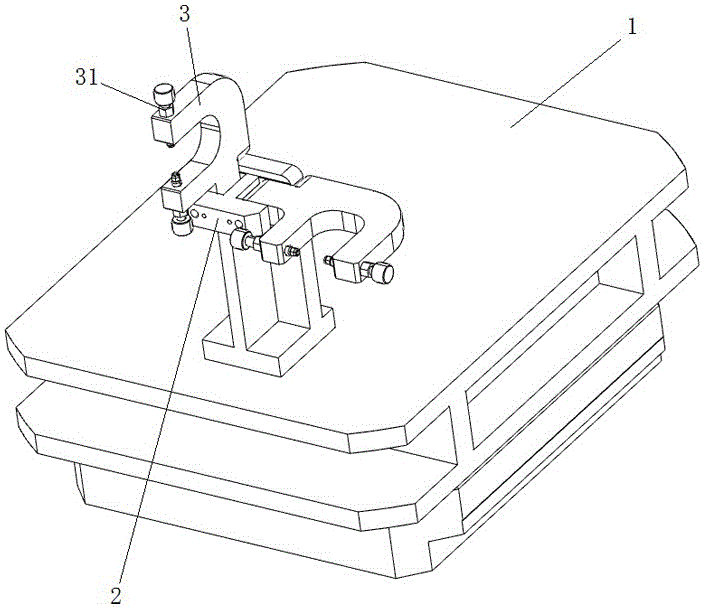

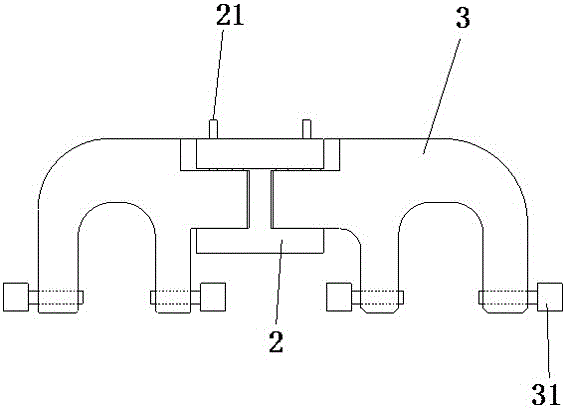

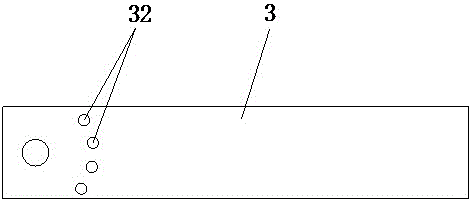

[0013] Embodiment one: if Figure 1~3 As shown, a C-type multi-angle manual self-locking turning mechanism includes a base 1, and the base 1 is provided with a fixing base 2, and the fixing base 2 is symmetrically hinged with two C-shaped handles 3. The fixed seat 2 is provided with spring pins 21 equal in number to the handle, and several positioning holes 32 arranged in an arc are evenly distributed on the side of the hinge of the handle, and these positioning holes are located on an arc with the same radius, so that The spring pin 21 is inserted into one of the positioning holes, and both ends of the handle are provided with threaded holes, and a locking screw 31 is provided in the threaded holes.

[0014] The included angles between the positioning holes are different, so that the handles can be located at different angles and be fixed at the angle positions.

[0015] In this embodiment, the outer end of the locking screw is provided with a textured handle.

[0016] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com