wiper blade

A wiper and wiper technology, which is applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problems of reduced versatility and cost rise of components, and achieve the effect of universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be described below based on the drawings.

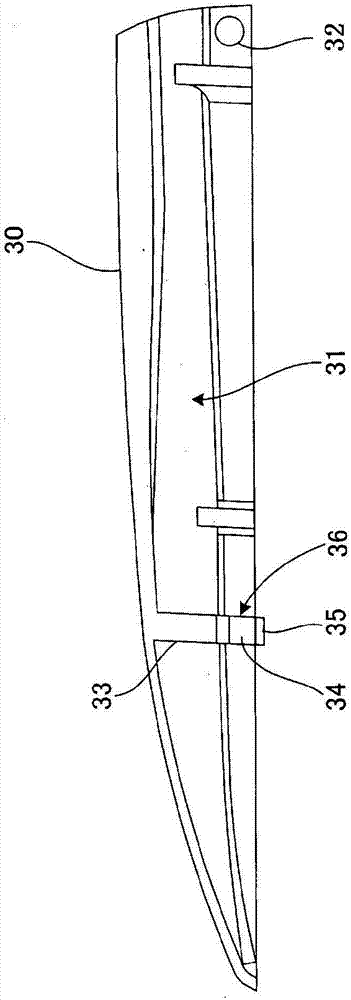

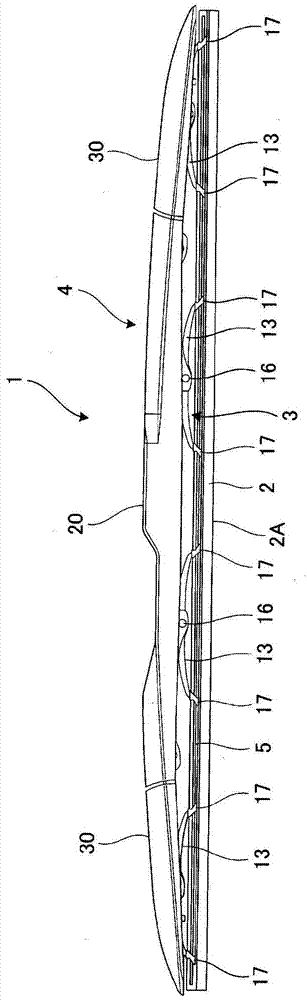

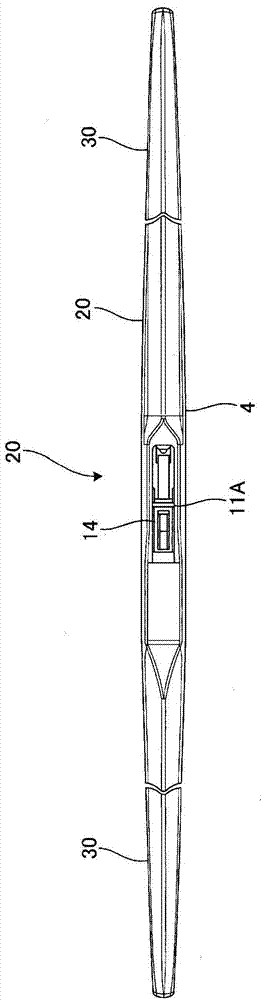

[0040] Figure 1 ~ Figure 3 The overall structure of the wiper blade 1 of the present invention is shown. As shown in the figure, the wiper blade 1 includes: a wiper rubber 2 , a support portion 3 supporting the wiper rubber 2 , and a covering portion 4 covering the support portion 3 .

[0041] The wiper rubber 2 is a long rubber member that wipes a surface to be wiped (not shown) such as a glass surface of an automobile, and is arranged at the lower end of the wiper blade 1 . During the wiping operation of the wiper blade 1 , the wiper rubber 2 moves along the surface to be wiped with the lower end portion 2A thereof pressed against the surface to be wiped.

[0042] Ridge members 5 , which are metal plate members extending in the longitudinal direction of the wiper rubber 2 , are attached to side portions on both sides of the wiper rubber 2 . The ridge member 5 functions so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com