Sealed connecting rod for guiding

A technology of guiding seals and connecting rods, which is applied in the field of connecting rods, can solve the problems of poor reliability and high processing cost of electrical connectors, achieve good practical performance, realize guiding functions, and realize the effects of interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

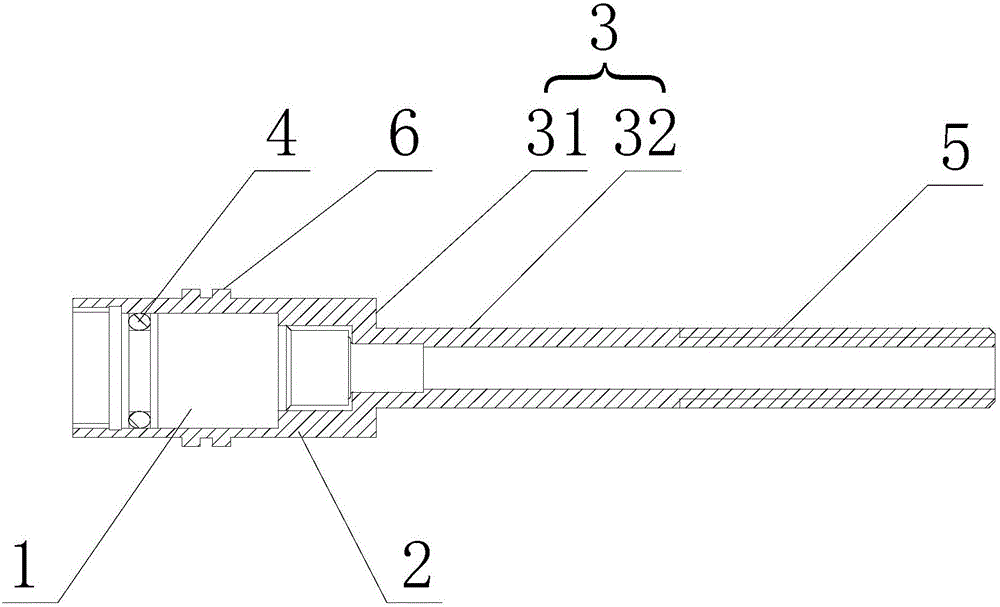

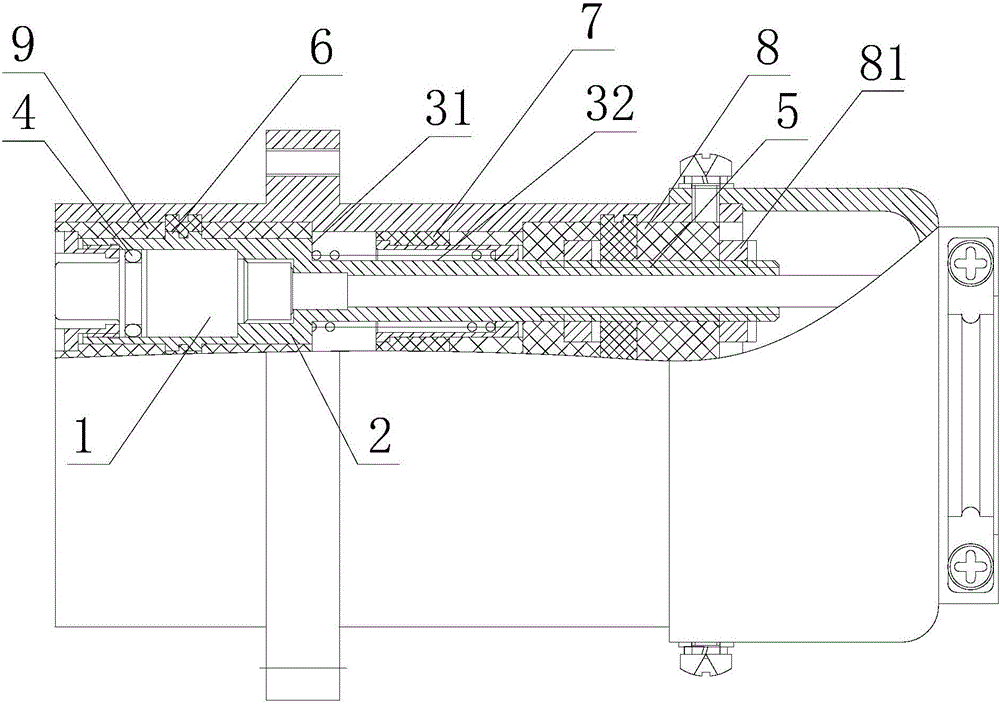

[0015] Such as figure 1 As shown, a guiding and sealing connecting rod includes a high-frequency contact piece 1 and a hollow rod body 2, the high-frequency contact piece 1 is detachably connected in the rod body 2, and the outer wall of the rod body 2 is provided with a power supply connector active layer left and right The moving guiding structure 3, the radial direction of the high-frequency contact piece 1 is connected with a sealing ring 4, one end of the rod body 2 is provided with a connecting section 5 connected to the sealing layer, and the other end of the rod body 2 is provided with a sealing layer connected to the electrical connector and the sealing layer of the electrical connector is in contact with the guiding movable structure 3. The guiding movable structure 3 includes a limiting part 31 and a guiding part 32. The limiting part 31 is arranged on the rod body 2, and one end of the guiding part 32 is in contact part 31, the other end of the guide part 32 commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com