Intelligent steel wire hooking device for optical cable twisting machine

A technology of stranding machine and wire hook, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., to achieve the effects of reducing the difficulty of hooking, low energy consumption, and convenient storage and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is described in detail:

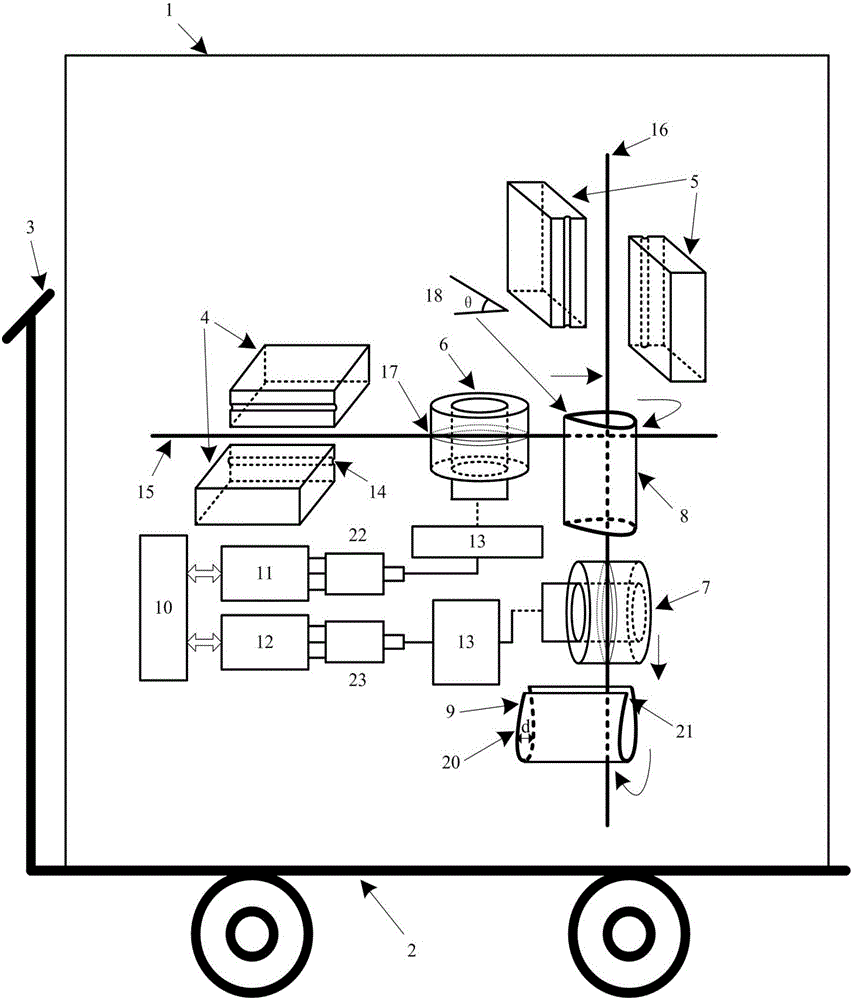

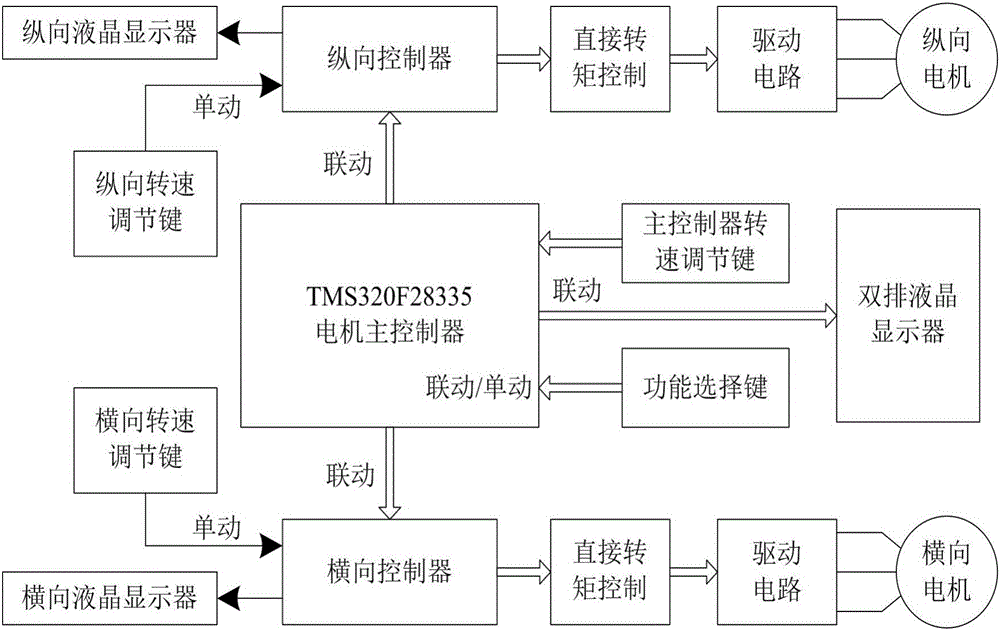

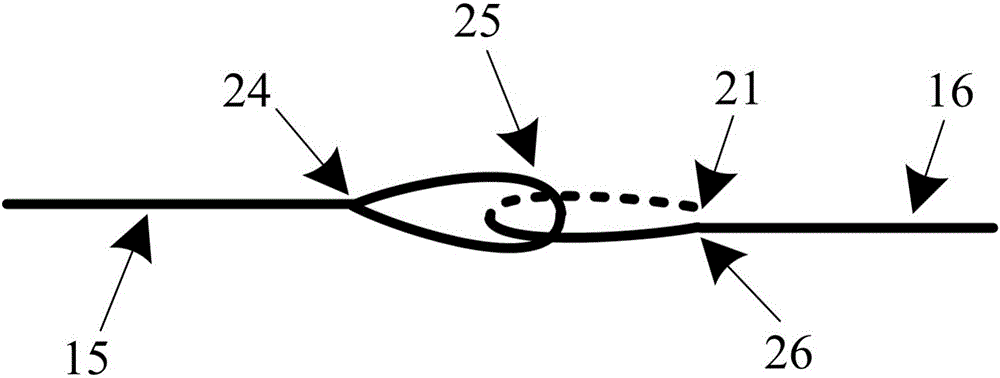

[0015] Such as figure 1 Shown, a kind of intelligent steel wire hanger that is used for optical cable stranding machine, comprises carrying module, steel wire fixing module, rolling module, track module and motor control module; Described carrying module comprises vertical cabinet 1, four-wheel trolley 2 and Handrail 3; The wire fixing module includes a horizontal wire anchor 4 and a longitudinal wire anchor 5; The rolling module includes a horizontal roller 6 and a longitudinal roller 7; Pressure track 9; the motor control module includes a motor main controller 10, a lateral controller 11, a longitudinal controller 12 and a mechanical transmission rod 13. The vertical cabinet 1 adopts a cuboid stainless steel cabinet with a height of 1.5m, a length of 0.8m, and a width of 0.4m, which is used for fixing and storing wire hooks. Connection; the four-wheel trolley 2 is used t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com