Anti-freezing oil tank and heating mode

A fuel tank, self-heating technology, applied in fuel heat treatment devices, engine components, machines/engines, etc., can solve problems such as freezing and blocking of oil circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

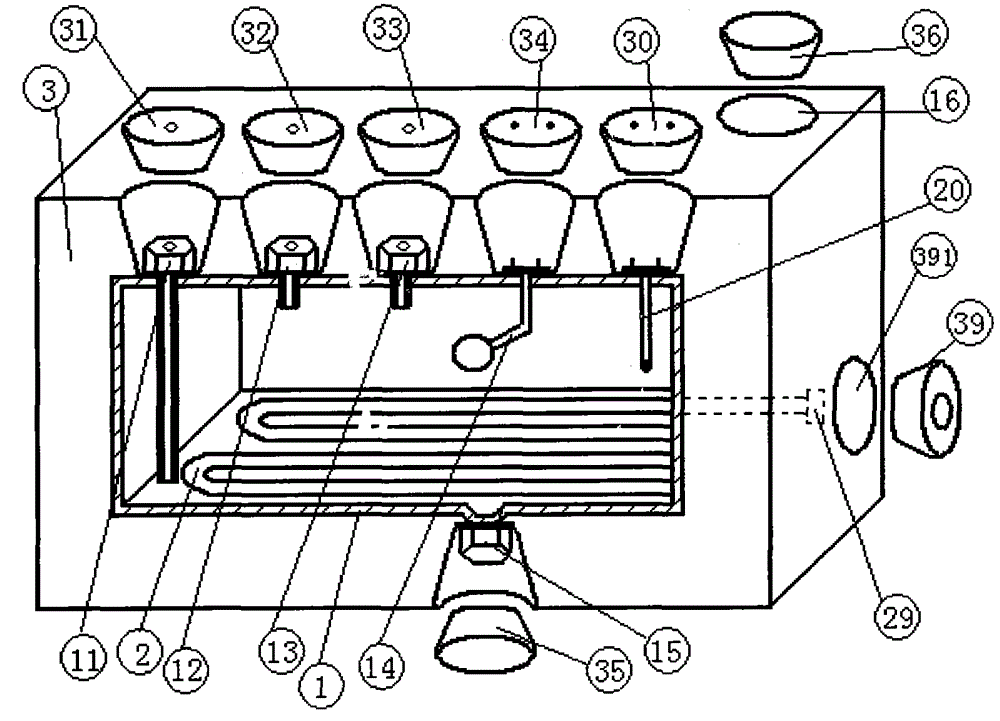

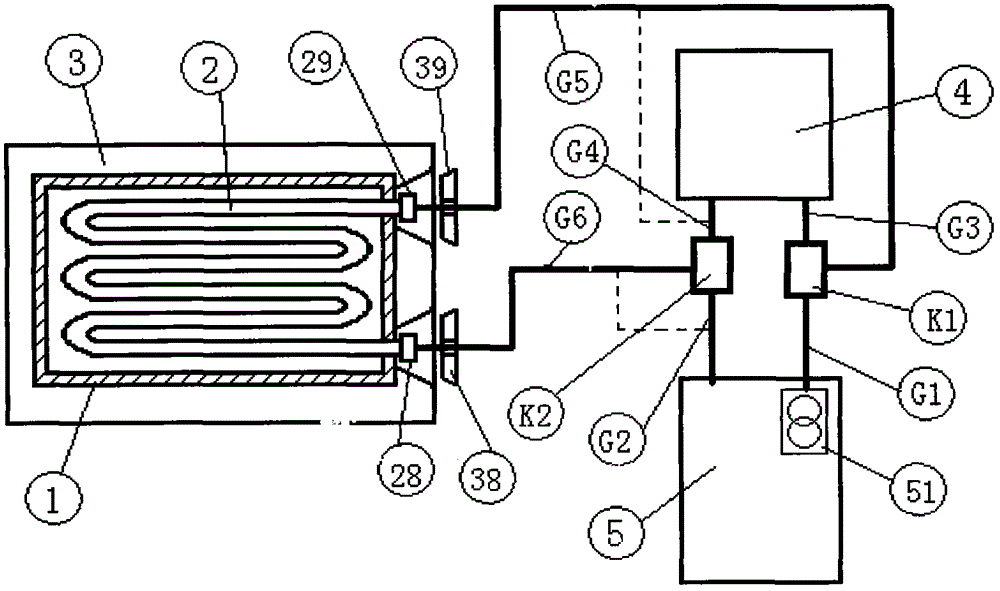

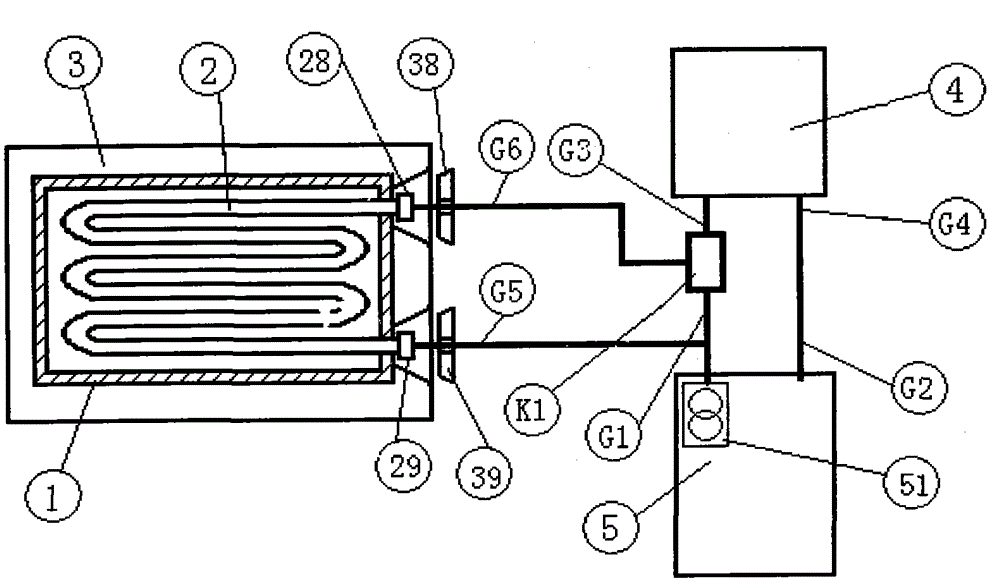

[0010] In the case of the fuel tank in the state of the art, the main body of the heat insulation layer is added to the outside of the inner core of the fuel tank; the main body of the heat insulation layer is made of poor thermal conductor material; the main body of the heat insulation layer is not only wrapped in the fuel tank On the outer side of the tank, there are loading and unloading holes required for the connecting device between the inner core of the fuel tank and the outside world; the loading and unloading holes required for the connecting device between the inner core of the fuel tank and the outside world are: loading and unloading holes for the oil outlet pipe, loading and unloading holes for the oil return pipe, and loading and unloading holes for the fuel tank intake pipe , loading and unloading hole for oil detection device, screw loading and unloading hole for the oil discharge port at the bottom of the fuel tank, loading and unloading hole for the oil filling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com