Novel dry ice cleaning device

A new type of dry ice cleaning technology, used in cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as ice blockage in ice distribution holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

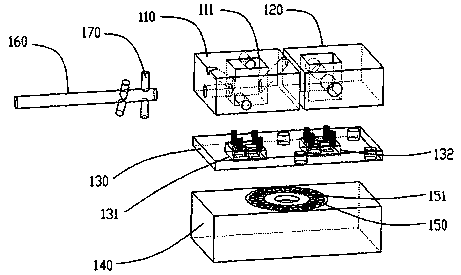

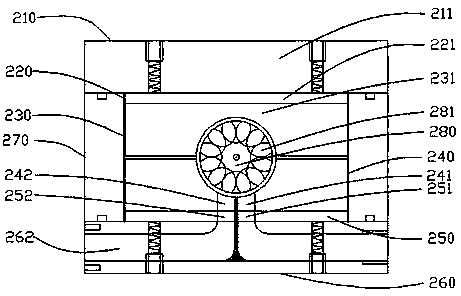

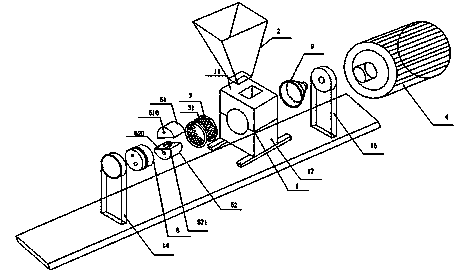

[0025] Such as image 3 and Figure 4 As shown, the present invention discloses a novel dry ice blasting device, which includes a machine base 1, a hopper 2, an ice wheel 3 and a motor 4; the top and bottom of the machine base 1 are respectively provided with an ice inlet and an ice outlet; The hopper 2 is arranged on the top of the ice inlet; the ice distribution wheel 3 is a hollow cylindrical structure, and ice distribution holes 31 are staggeredly distributed on its axial circumferential surface, and the ice distribution wheel 3 is arranged in a rotatable manner. On the center of the base 1, the motor 4 is connected with the ice distribution wheel 3 through a rotating shaft; it also includes a mandrel 5, an air connection pipe 6 for pushing half shafts and a air connection pipe 7 for drying ice, and the mandrel 5 includes a first half shaft 51 and a second half shaft 52, the first half shaft 51 is provided with a push half shaft air groove 510, the second half shaft 52 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com