Patents

Literature

36results about How to "Increase the spray force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

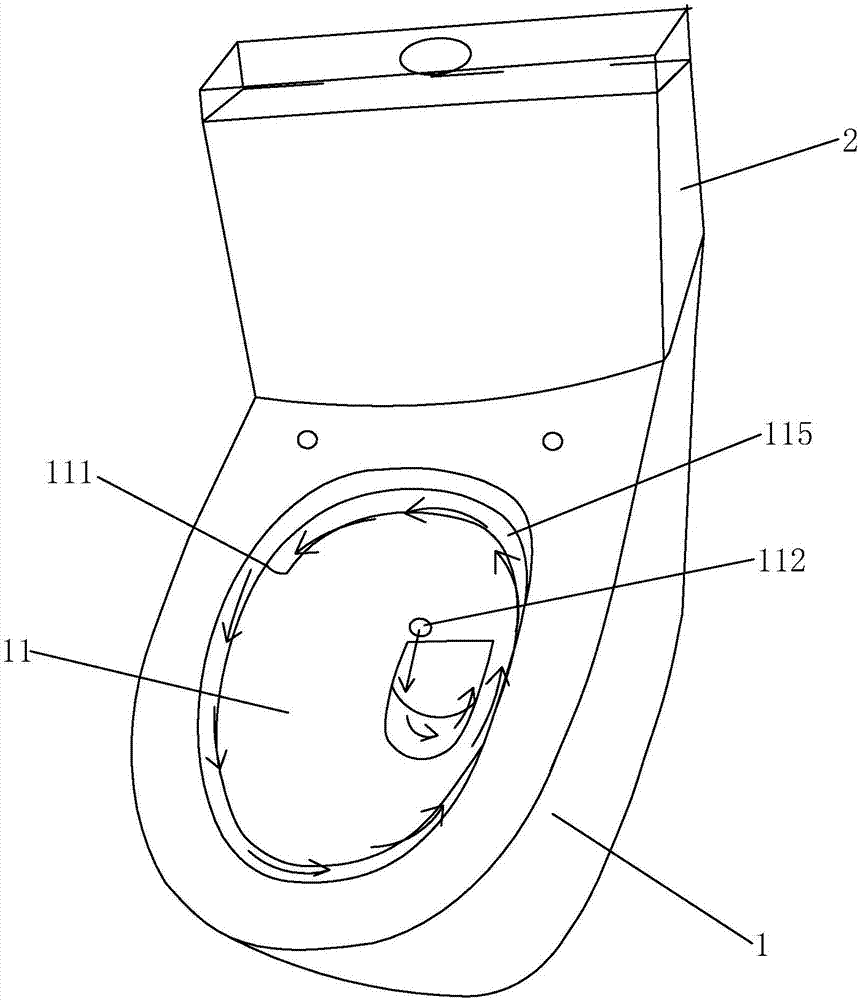

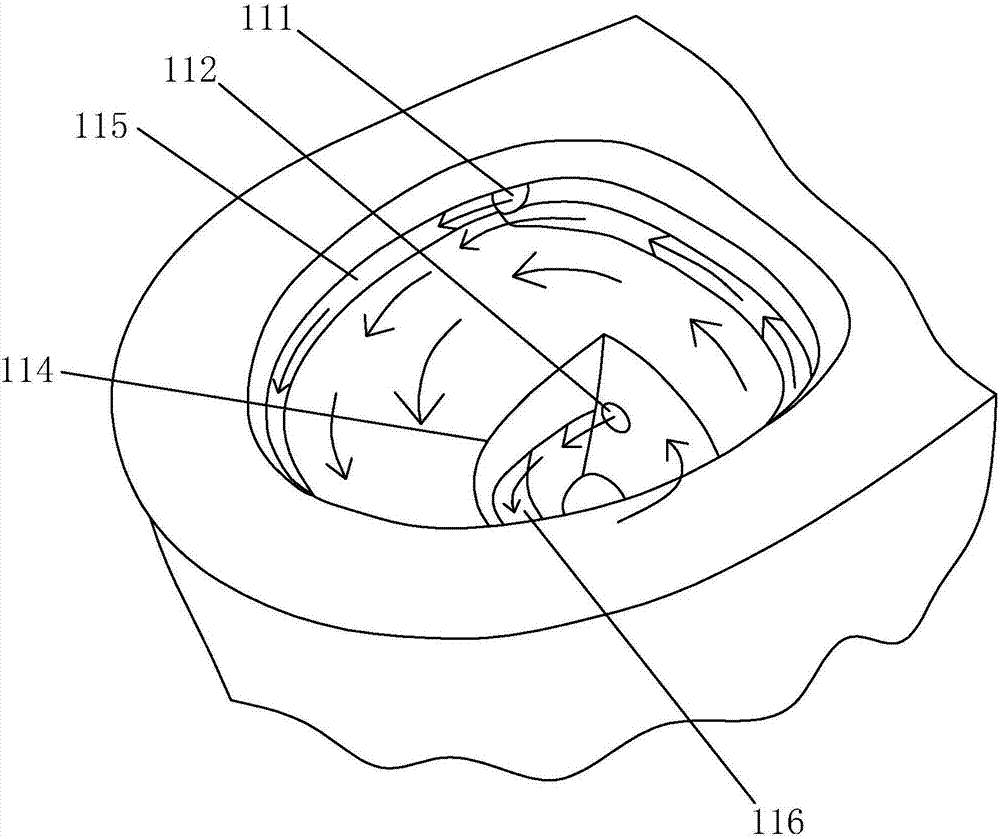

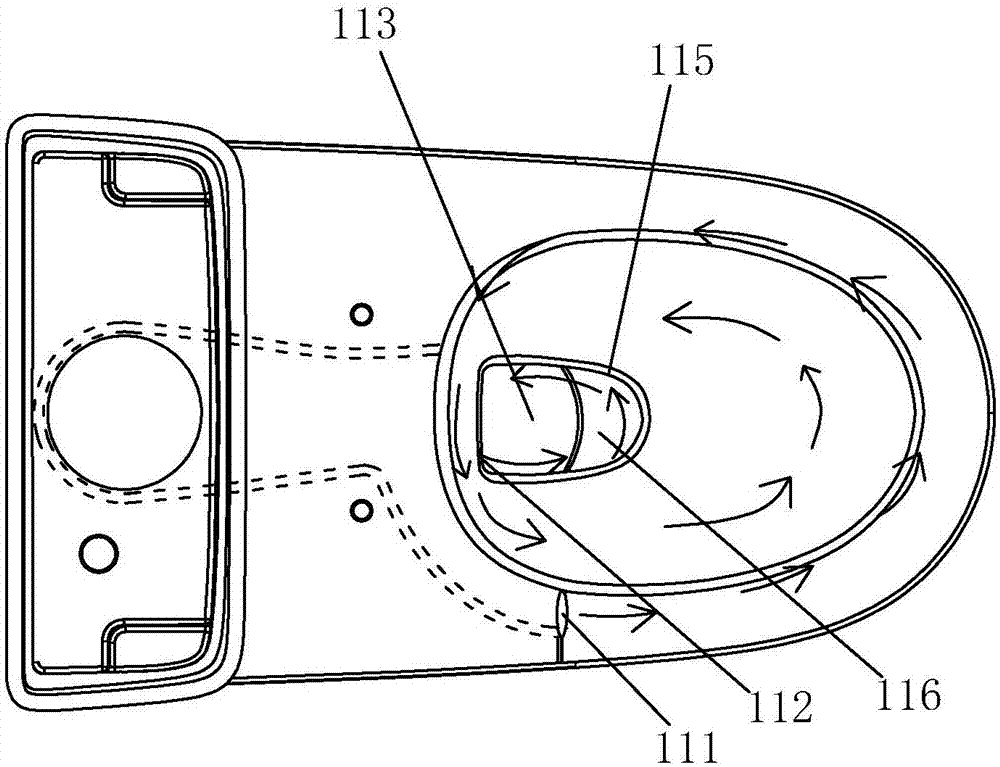

3D super-swirling siphon closestool

The invention discloses a 3D super-swirling siphon closestool. The 3D super-swirling siphon closestool comprises a closestool main body, wherein the closestool main body comprises a closestool tank, a siphon pipe, a flushing water passage and a jetting water passage; a flushing hole is formed in the top of the closestool tank; a jet orifice and a drain outlet are formed in the bottom of the closestool tank; the flushing hole is communicated with the flushing water passage; the jet orifice is communicated with the jetting water passage; the drain outlet is communicated with the siphon pipe; an angle is formed between the hole surface of the flushing hole and the side surface of the closestool tank, so that water jetted from the flushing hole does circumferential movement around the closestool tank to form a first swirl; the jet orifice is formed in the side of the closestool tank, water jetted from the jet orifice does circumferential movement around the closestool tank to form a second swirl; the second swirl and the first swirl have the same swirling direction. The 3D super-swirling siphon closestool can achieve a double-swirl water flow, speeds up siphon, speeds up drainage, sufficiently reduces noises and has significant water-saving and draining effects.

Owner:JOMOO KITCHEN & BATHROOM

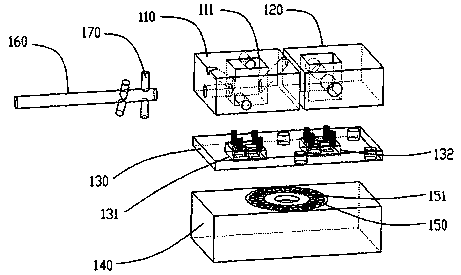

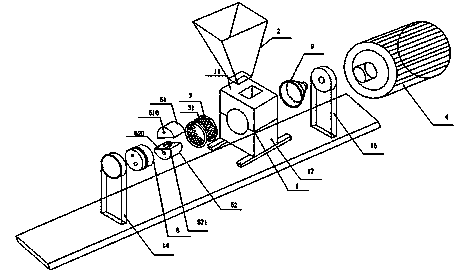

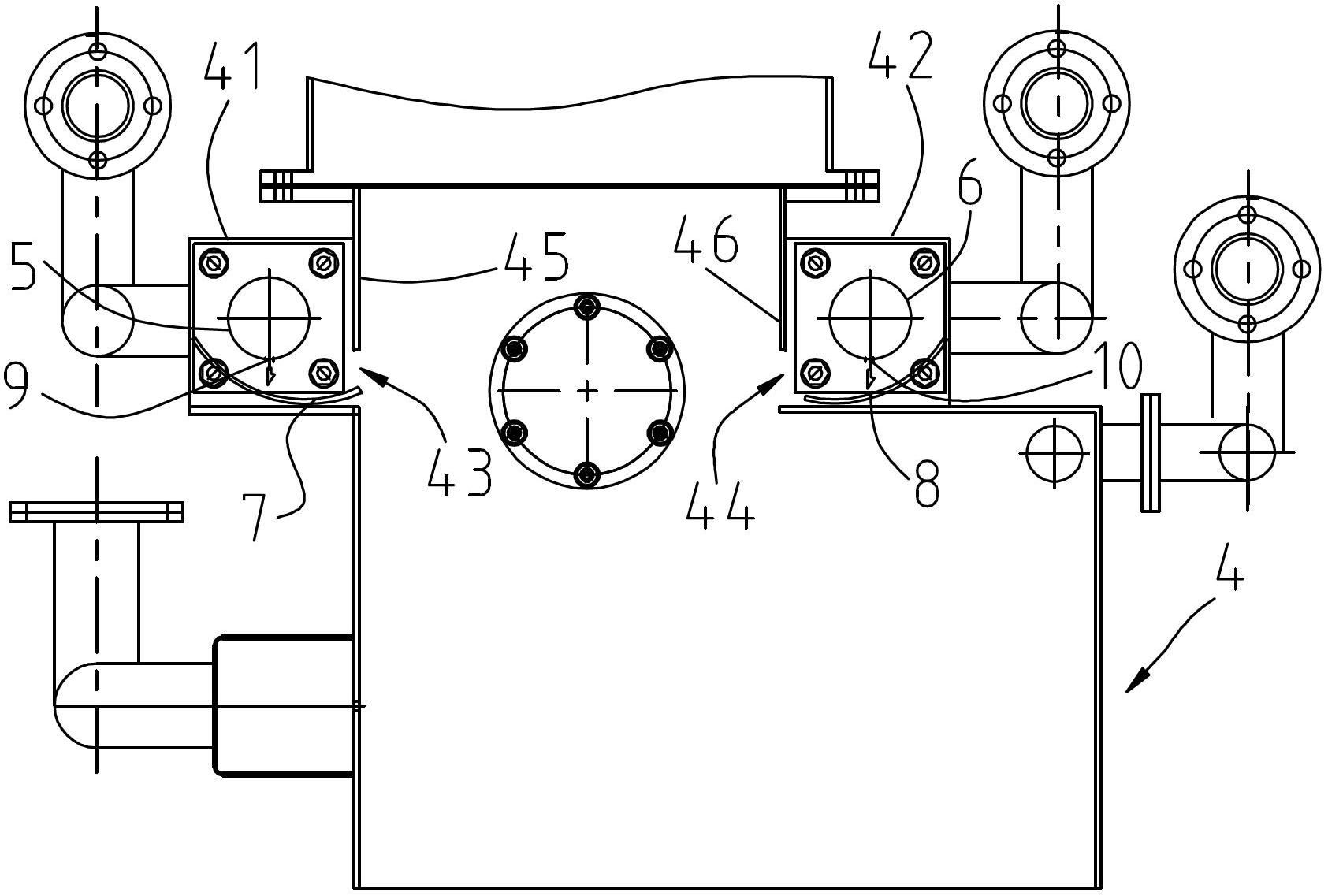

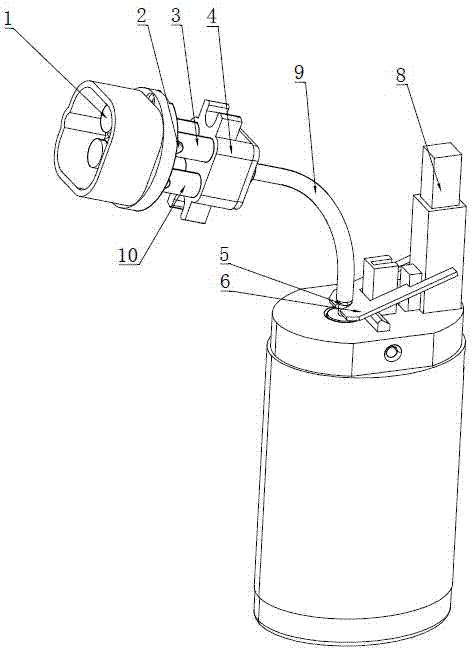

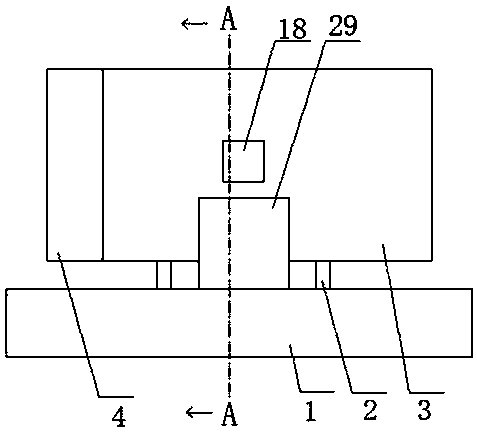

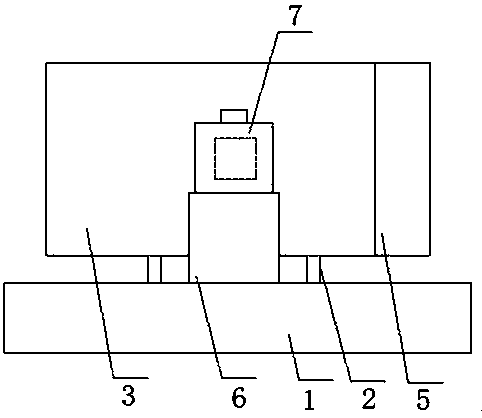

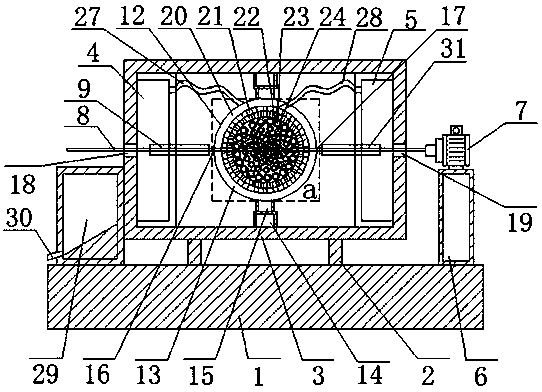

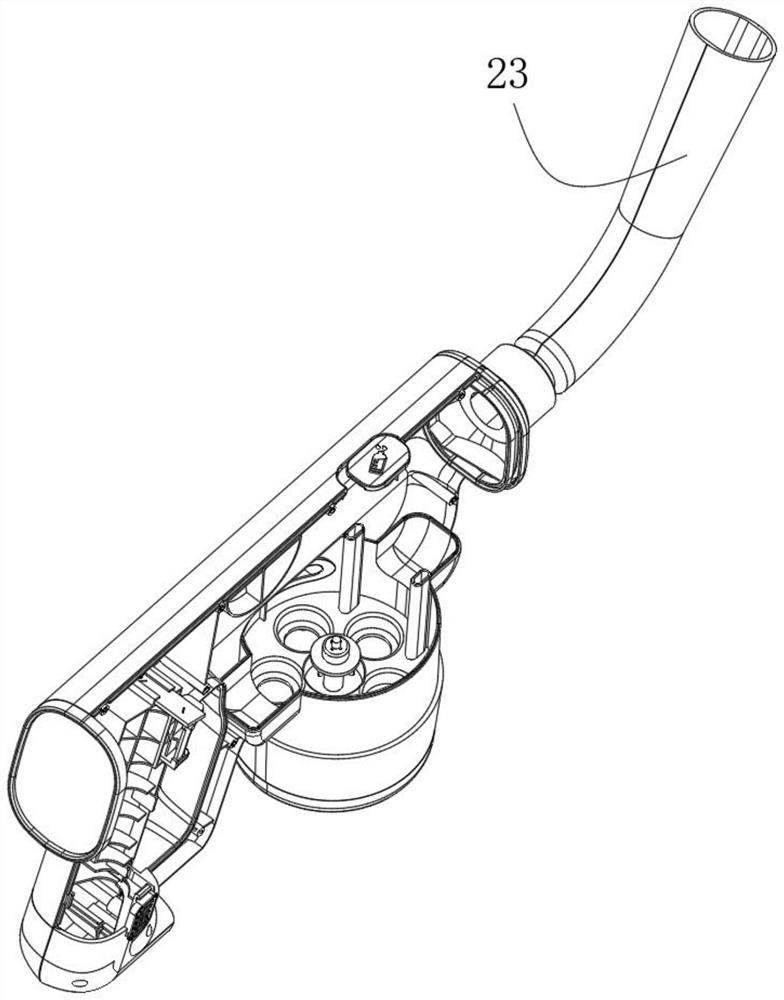

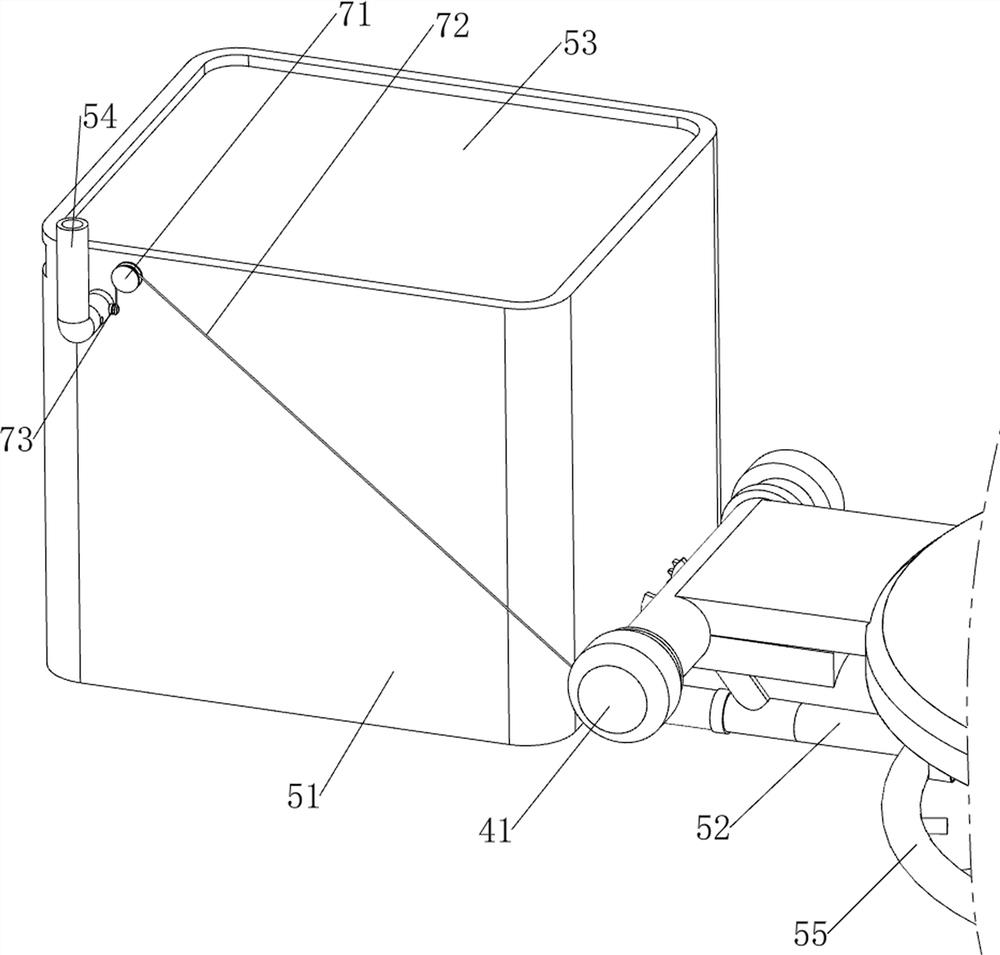

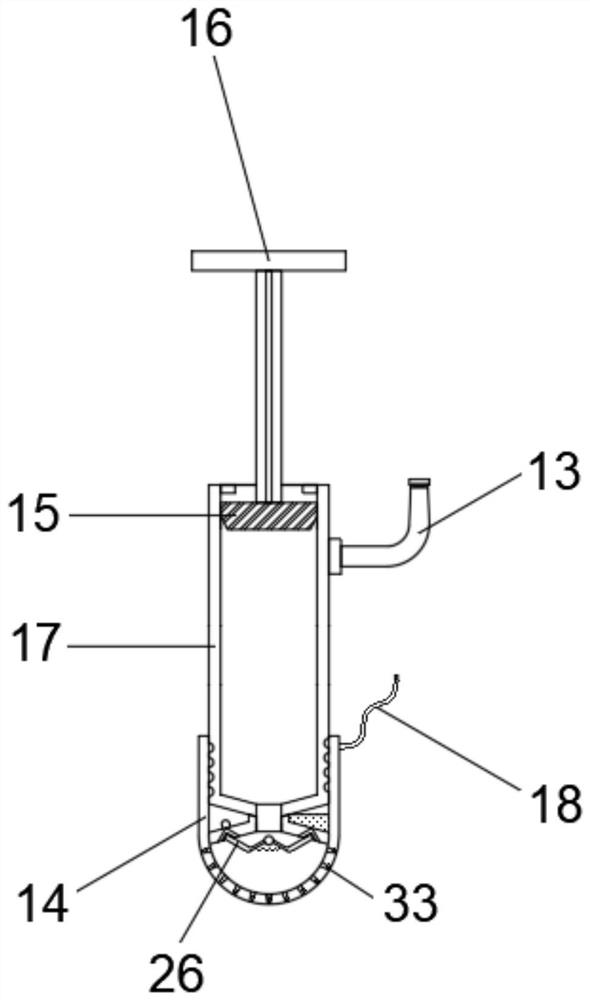

Novel dry ice cleaning device

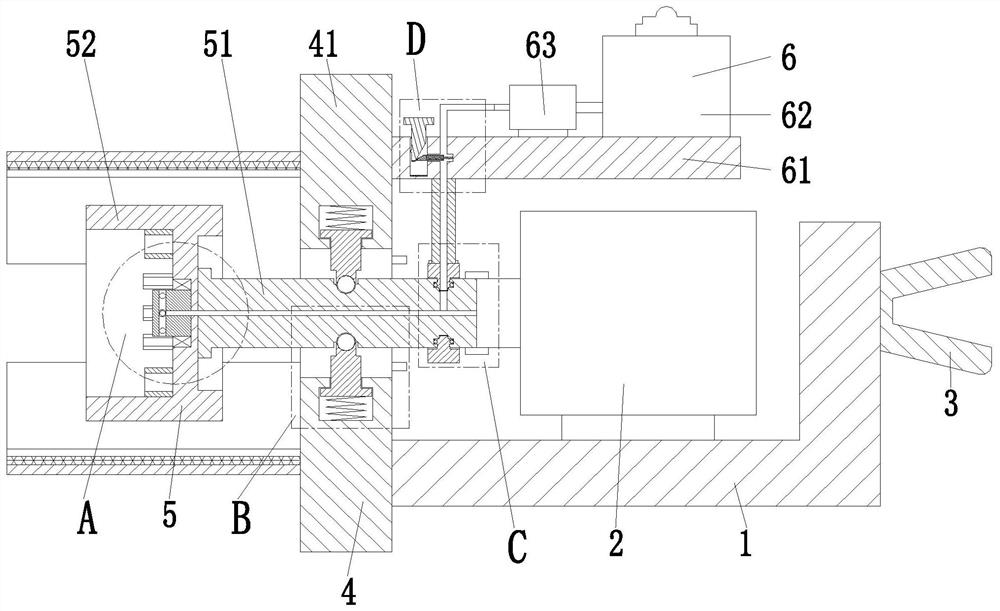

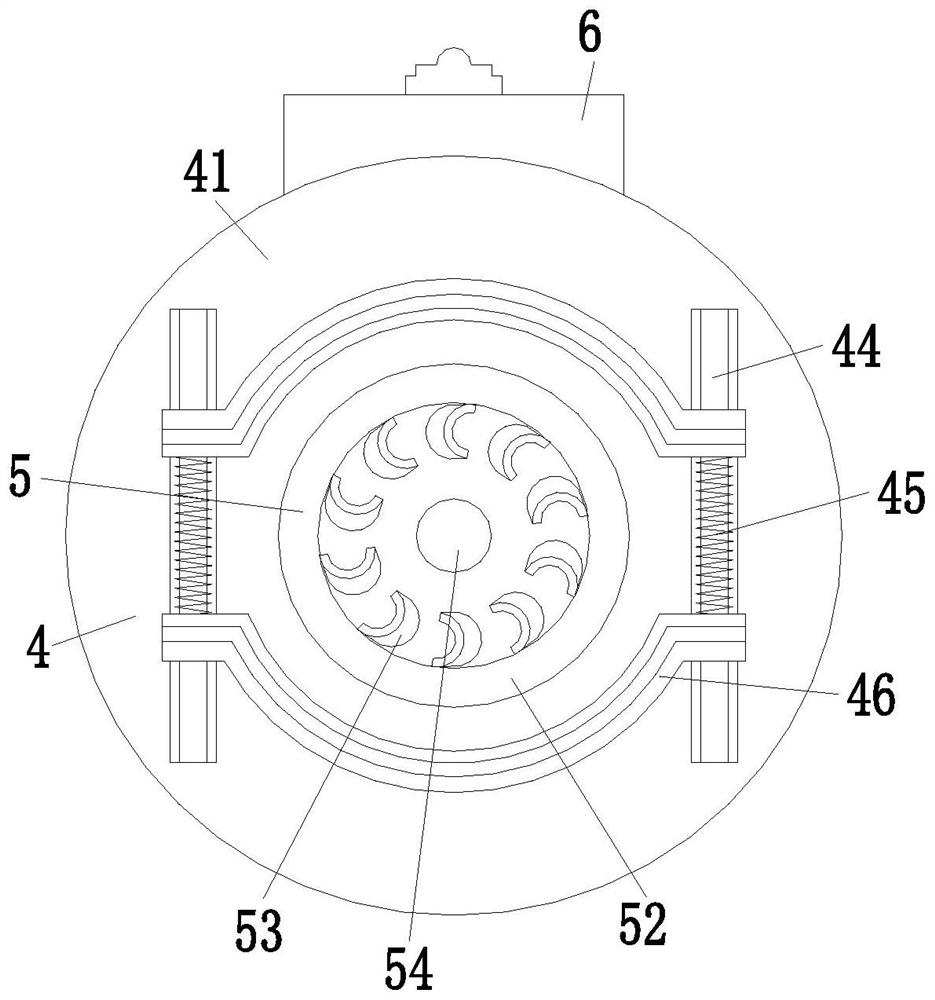

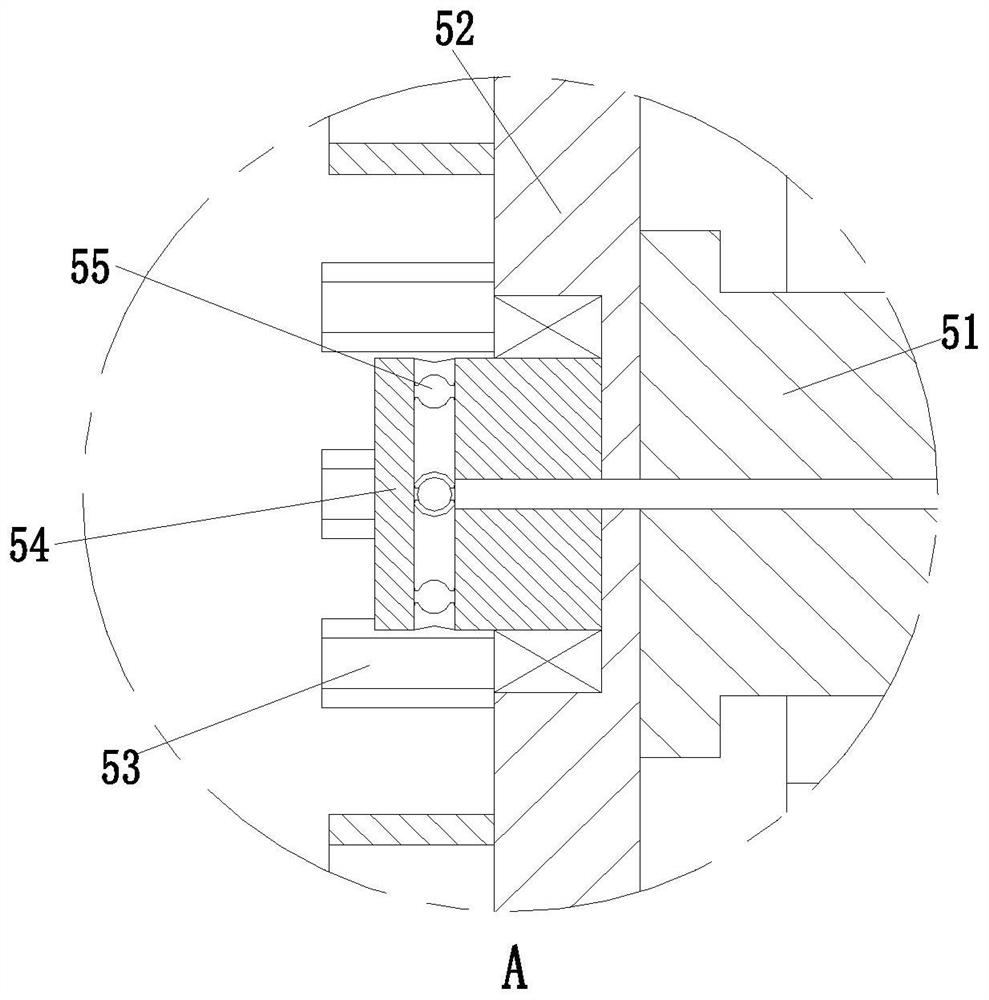

ActiveCN103406310ASolve the problem of freezing blockageIncrease the spray forceCleaning processes and apparatusDry iceEngineering

The invention discloses a novel dry ice cleaning device. The device comprises a base, a hopper, an ice preparing wheel, an electric motor, a mandrel, a half-shaft pushing air connecting pipe and a dry ice blowing air connecting pipe; an ice inlet and an ice outlet are arranged at the top and the bottom of the base respectively; the hopper is arranged at the top of the ice inlet; the ice preparing wheel is in a hollow cylindrical structure, ice preparing holes are formed in an axial circumferential face of the ice preparing wheel in a staggered mode, the ice preparing wheel is rotatably arranged at the center of the base, and the electric motor is connected with the ice preparing wheel through a rotating shaft; the mandrel comprises a first half shaft and a second half shaft; the first half shaft is in key connection with the second half shaft, and the mandrel is arranged at the center of the ice preparing wheel; the half-shaft pushing air connecting pipe and the dry ice blowing air connecting pipe are arranged outside the base. By the aid of the device, the problem of icing blockage of the ice preparing holes in the prior art can be effectively solved, and meanwhile, the jetting force of dry ice particles is increased.

Owner:XIAMEN JINRUIYI IND & TRADING CO LTD

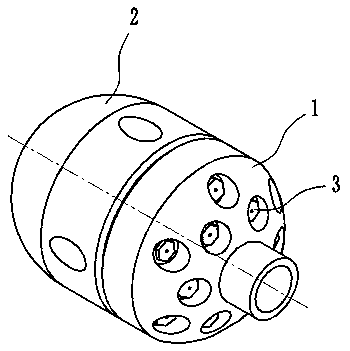

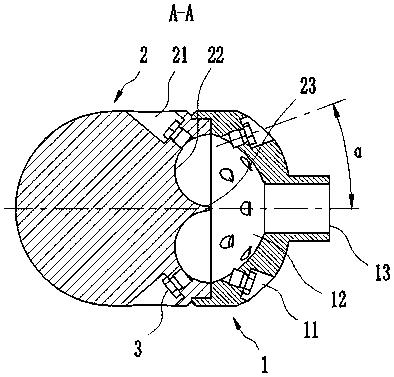

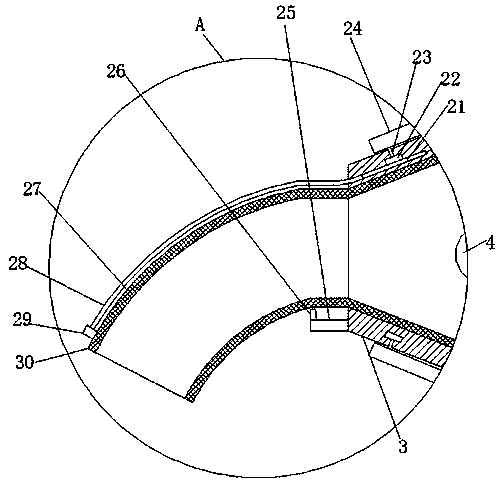

Air splitting type spouting head

InactiveCN106498948AIncrease the spray forceEasy to fillUnderground chambersFoundation engineeringRubber materialSpray nozzle

The invention provides an air splitting type spouting head. The air splitting type spouting head comprises a connecting pipe, a nozzle, an air mixing pipe and an air mixing pipe sleeve. An annular groove formed in the air mixing pipe and the air mixing pipe sleeve form an amplification chamber, the amplification chamber, a side opening in the air mixing pipe sleeve and amplification holes in the annular groove form an amplification channel, secondary power is provided through the amplification channel, the spouting strength of the nozzle is improved, the spouting distance is increased, accelerating agents are injected into the air mixing pipe through the amplification channel, and filling of the accelerating agents is convenient. Through the holes formed around the annular groove and inclined inwards, air and the accelerating agents can enter the air mixing pipe easily, the phenomenon that the air flows back can be avoided, and the accelerating agents can be uniformly mixed with spouted materials. The nozzle is made of elastic rubber materials, so that the blockage phenomenon of common metal nozzles is avoided, when slurry is partially blocked, the pressure of the blockage part is increased, the slurry is automatically spouted when the pressure is increased by a certain value, the nozzle does not need to be disassembled, material leakage is prevented in the spouting process, and raw materials are saved.

Owner:平顶山鸿顺源工贸有限公司

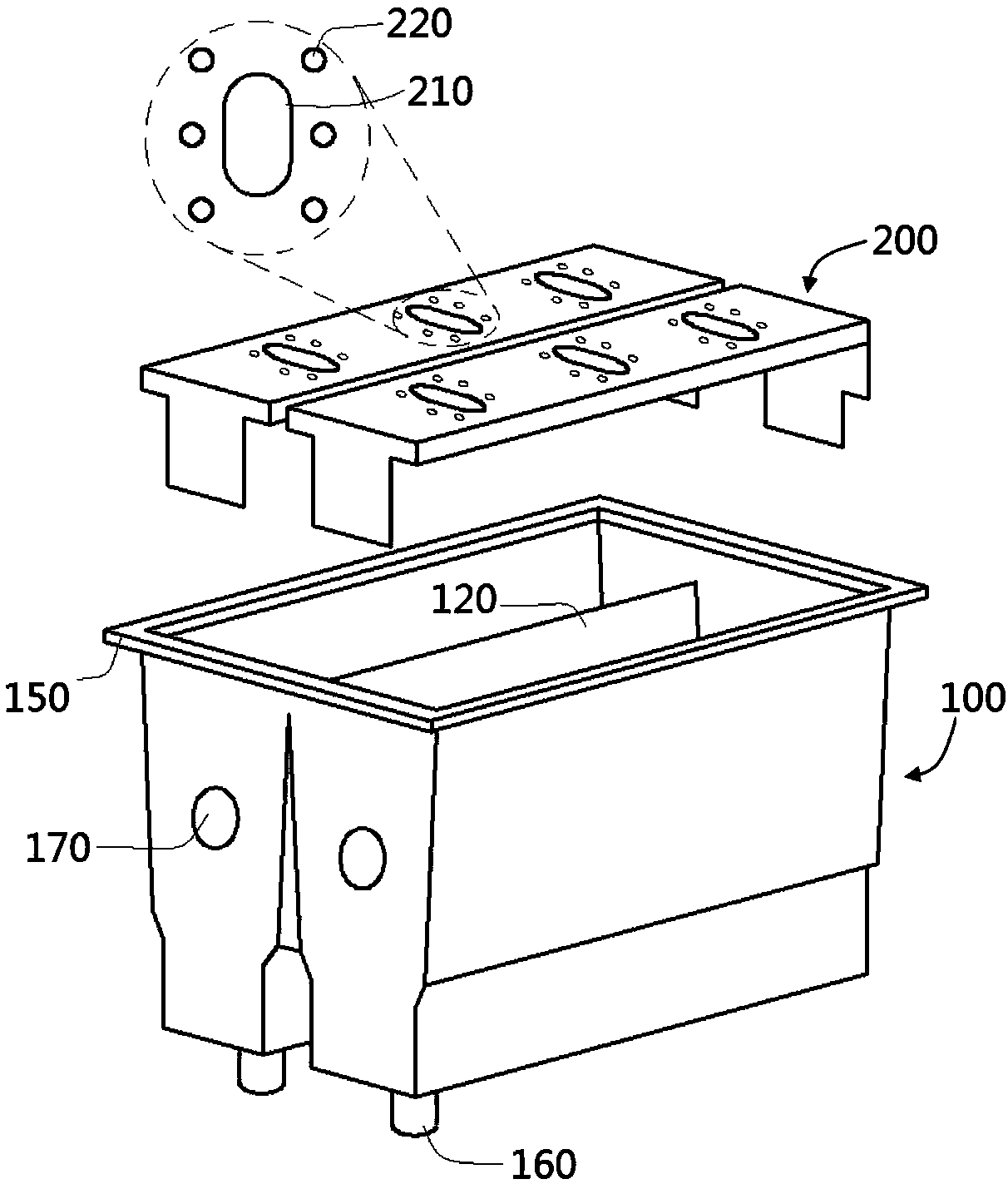

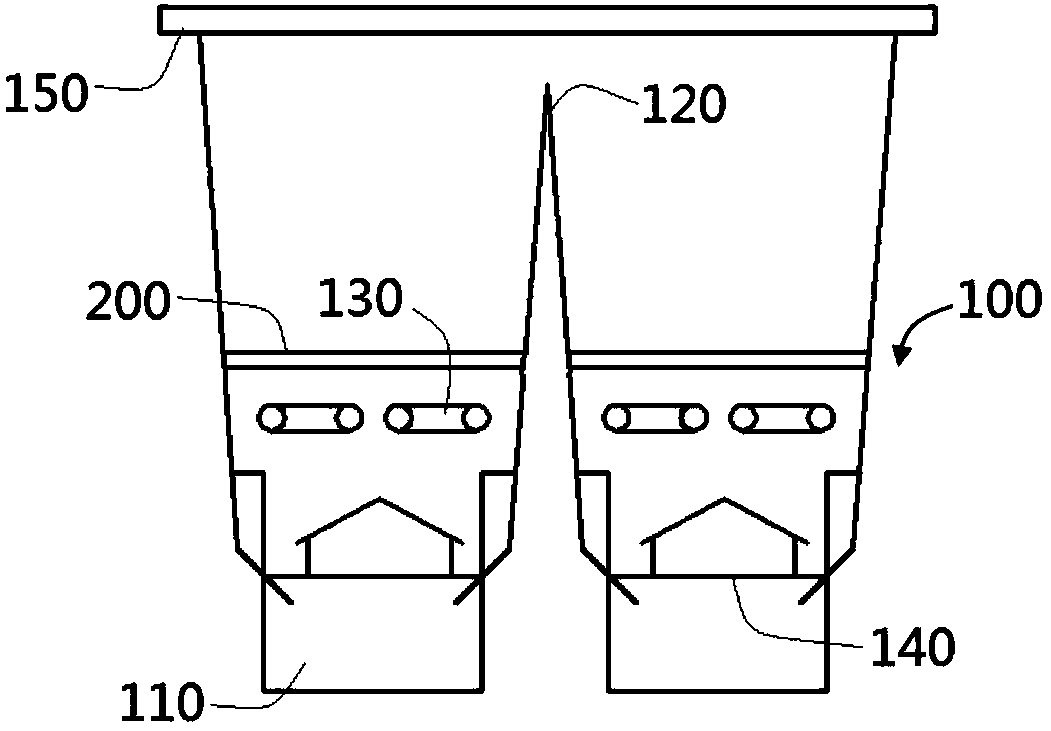

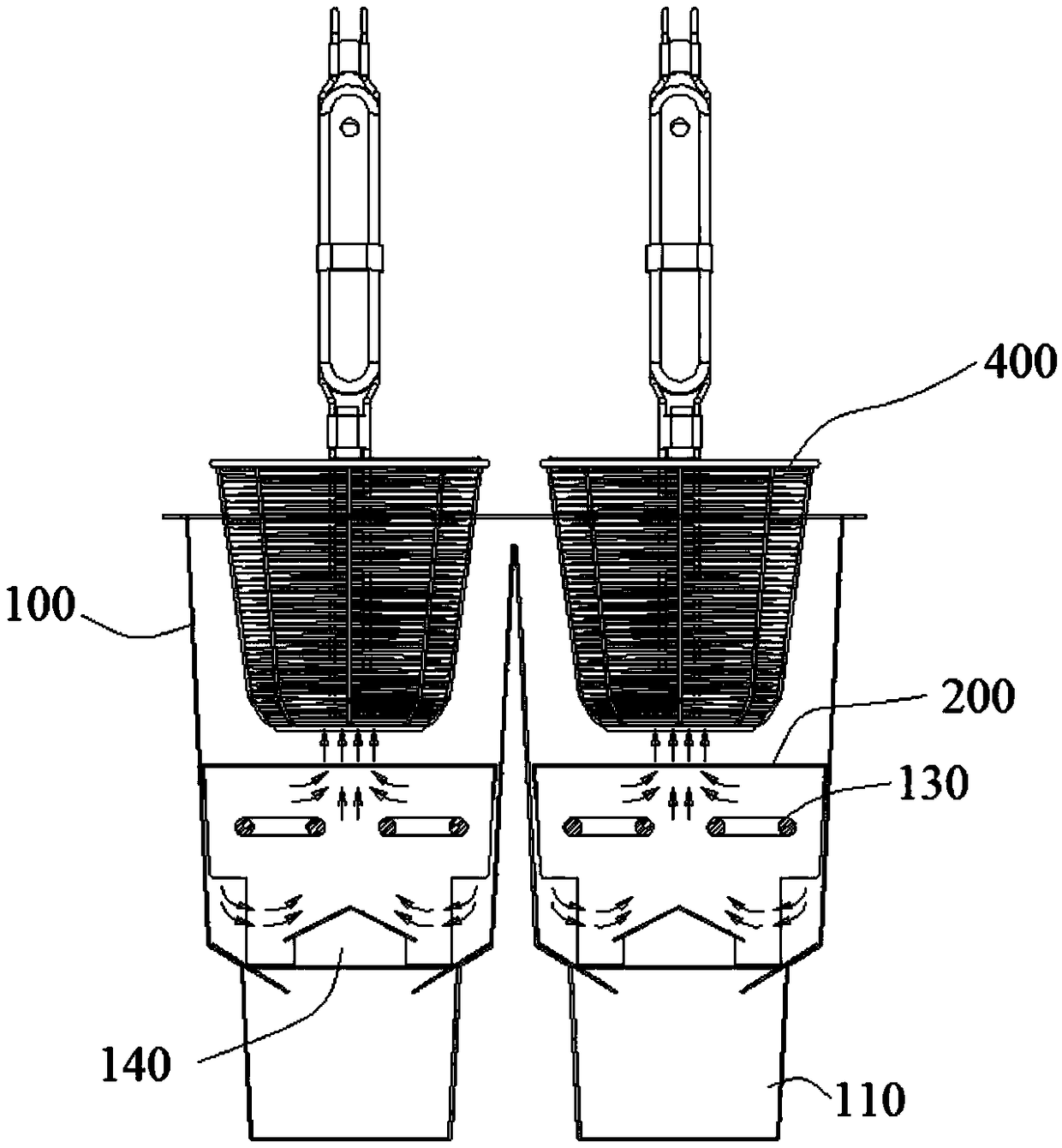

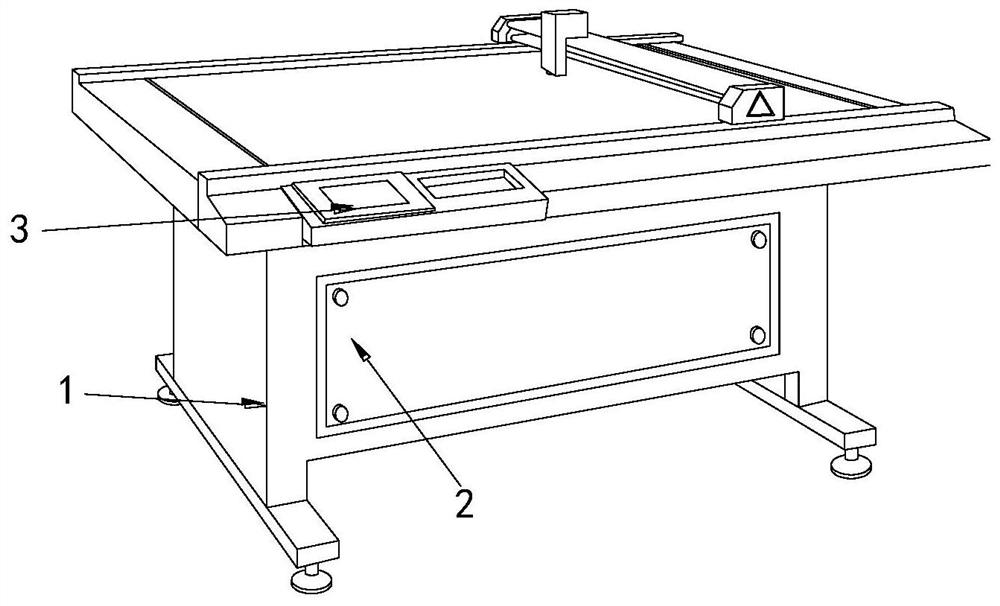

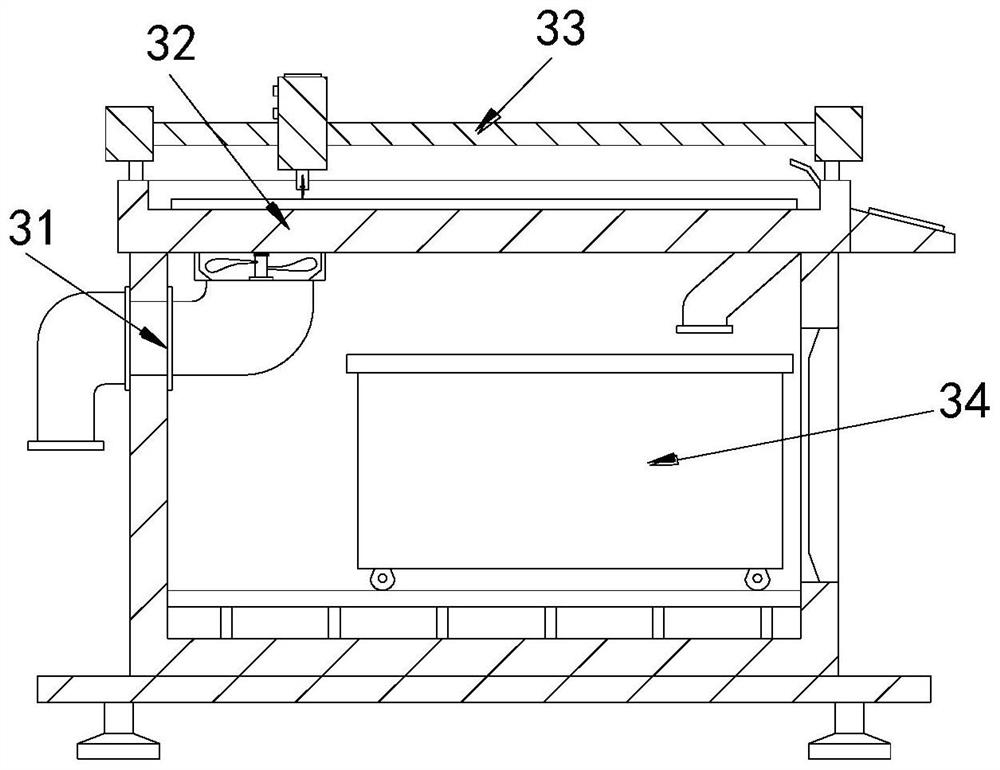

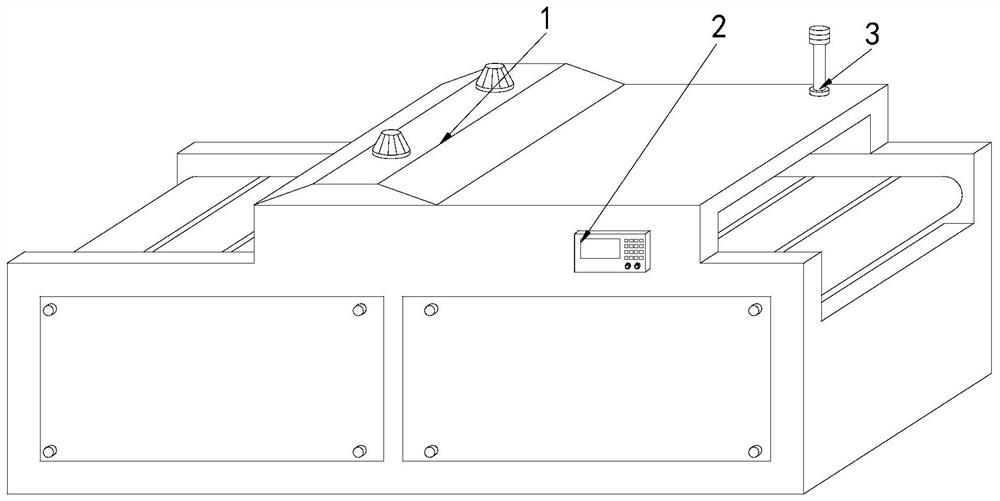

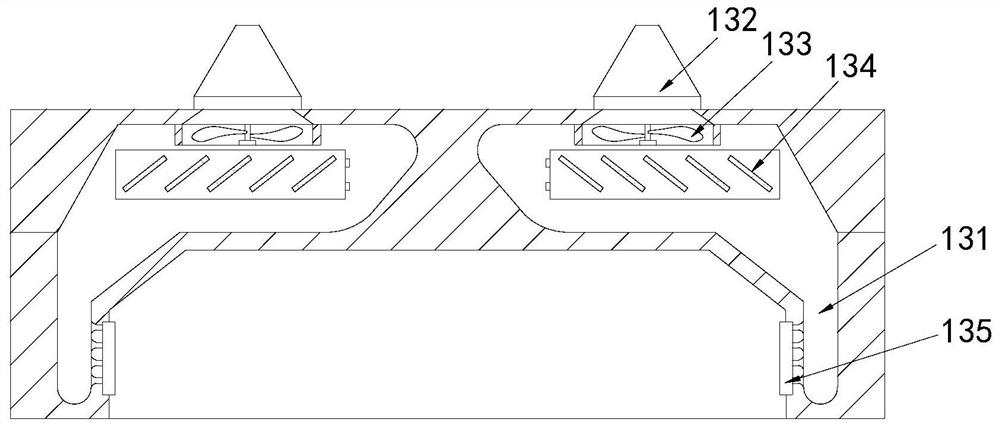

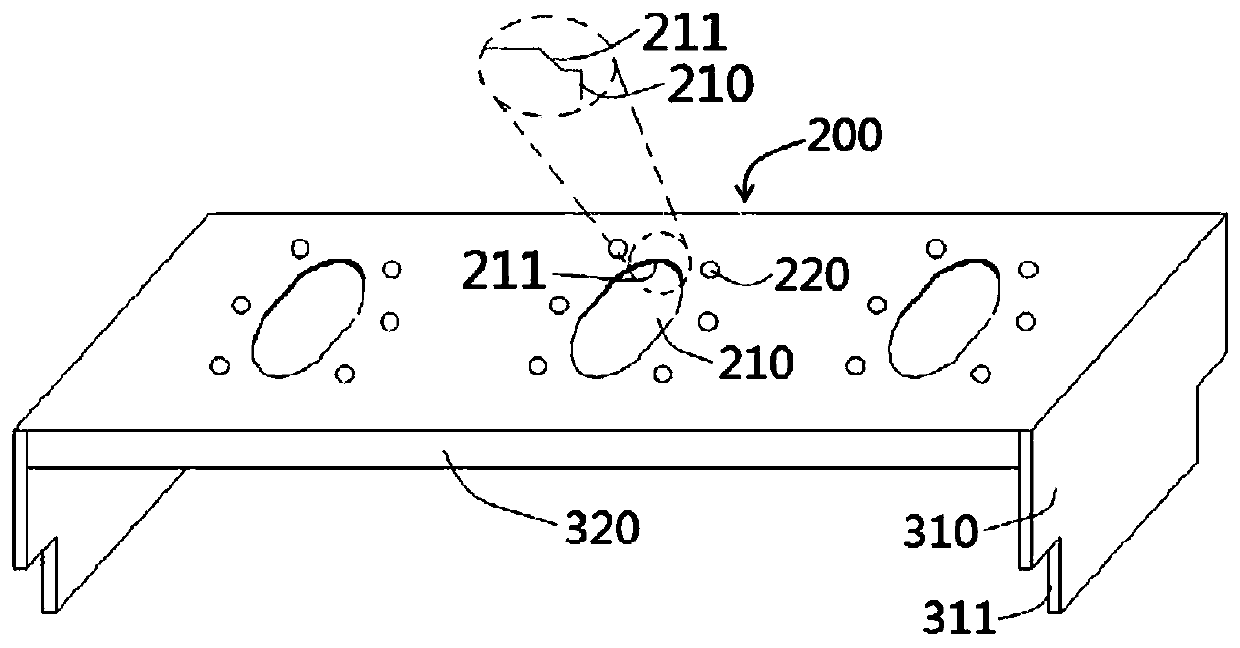

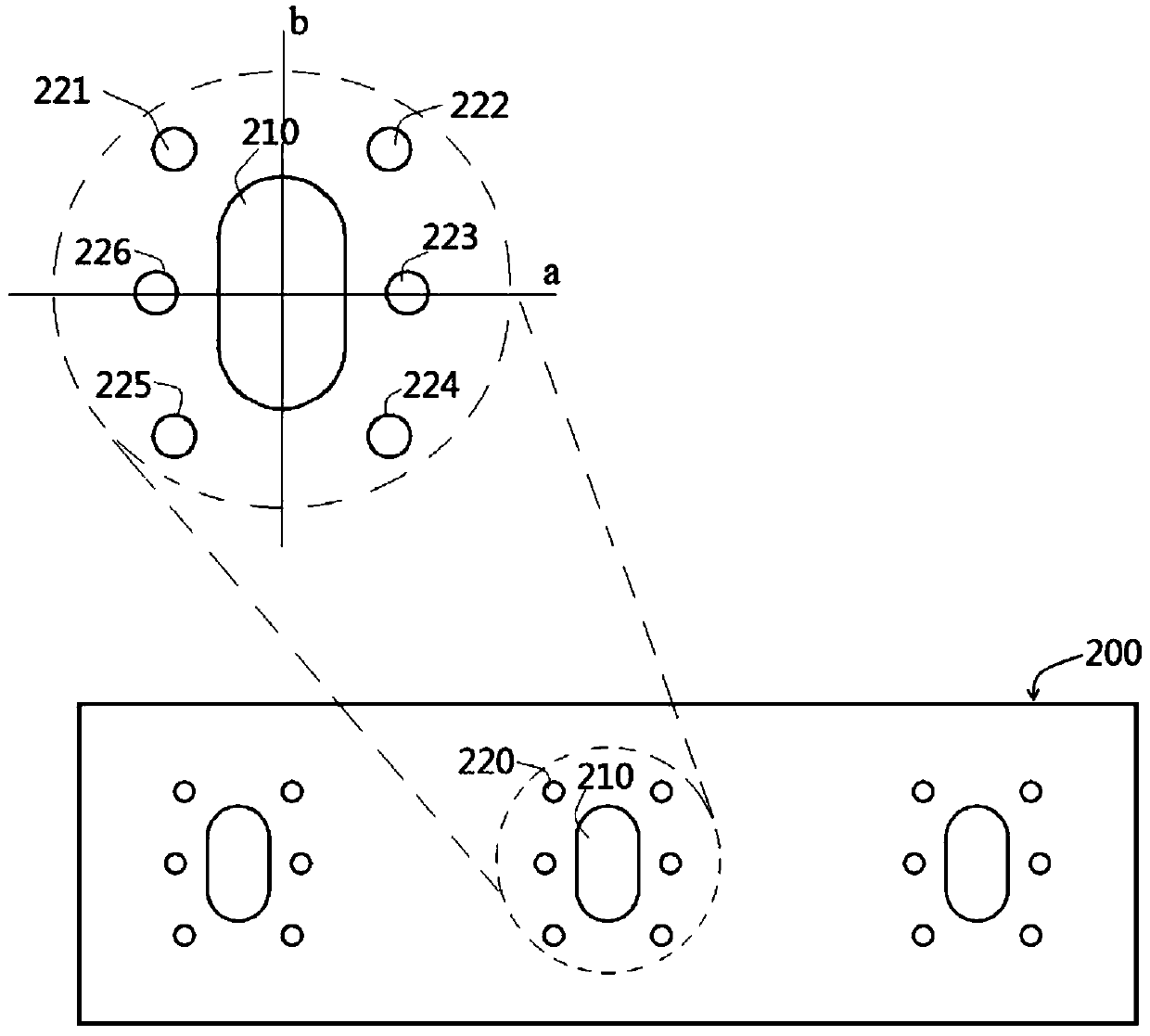

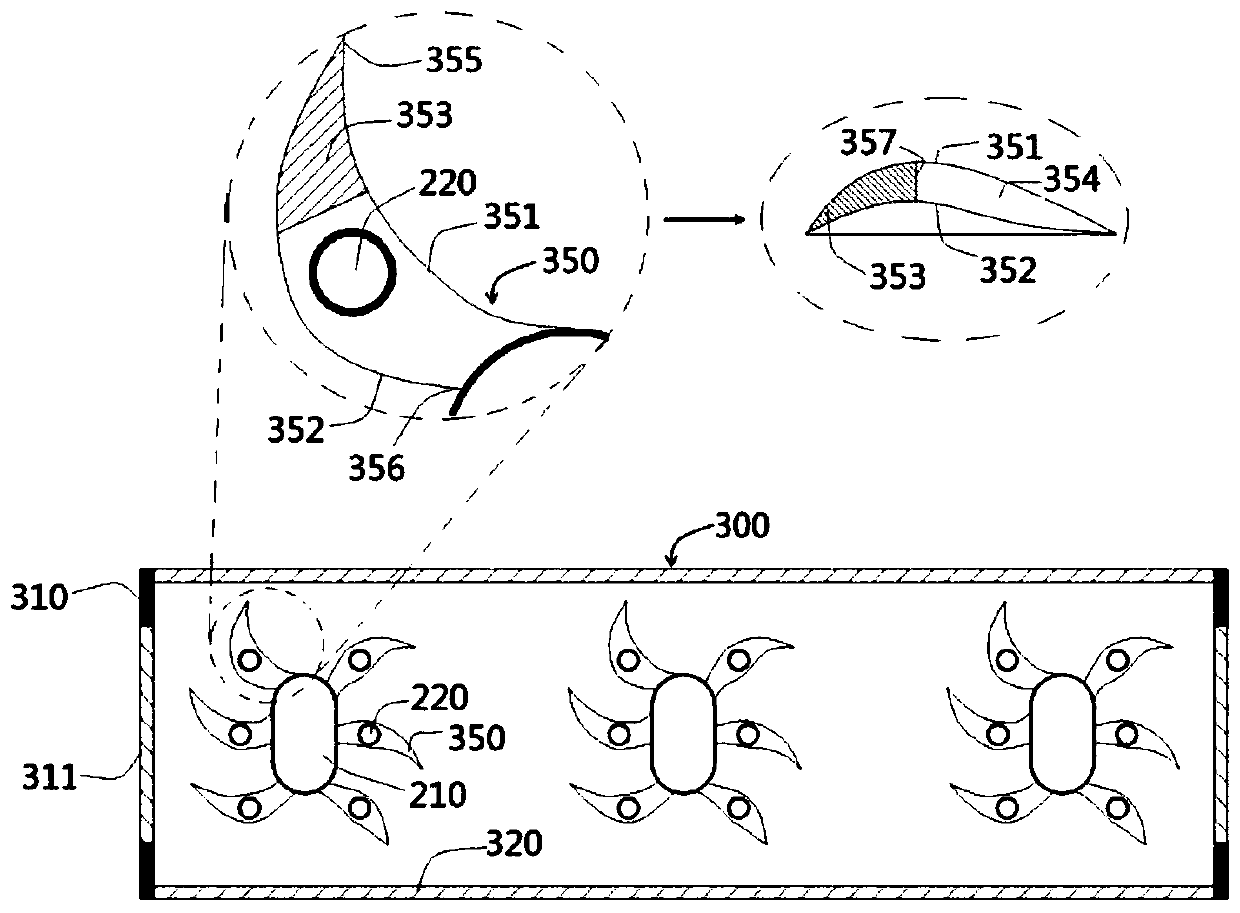

Noodle boiling furnace with jet flow plate and noodle boiling method thereof

ActiveCN108158384APrevent undershockHigh heat transfer efficiencyCooking vessel constructionsEngineeringHeating effect

The invention relates to a noodle boiling furnace with a jet flow plate and a noodle boiling method thereof, and belongs to the field of food processing equipment. A jet flow plate main body is arranged on a noodle boiling furnace body; the jet flow plate main body is provided with main water spraying holes and auxiliary water spraying holes; the noodle boiling furnace body comprises a depositioncabin and heating pipes; the deposition cabin is used for collecting food residue; the heating pipes are used for heating water and are arranged at the upper end of the deposition cabin; the jet flowplate main body is arranged at the upper end of the heating pipes; and the jet flow plate main body is used for spraying water heated by the heating pipes at the lower part to the upper side for boiling noodles. The boiling hot water under the jet flow plate main body can be sprayed to the upper side of the jet flow plate main body through the water spraying holes; the hot water impacts the doughto generate a rolling effect; when the water flow of the main water spraying holes impacts the dough, the water flow sprayed from the auxiliary water spraying holes impacts the periphery of the dough;and the heating rate and the heating effect are further improved.

Owner:ANHUI HUALING KITCHEN EQUIP

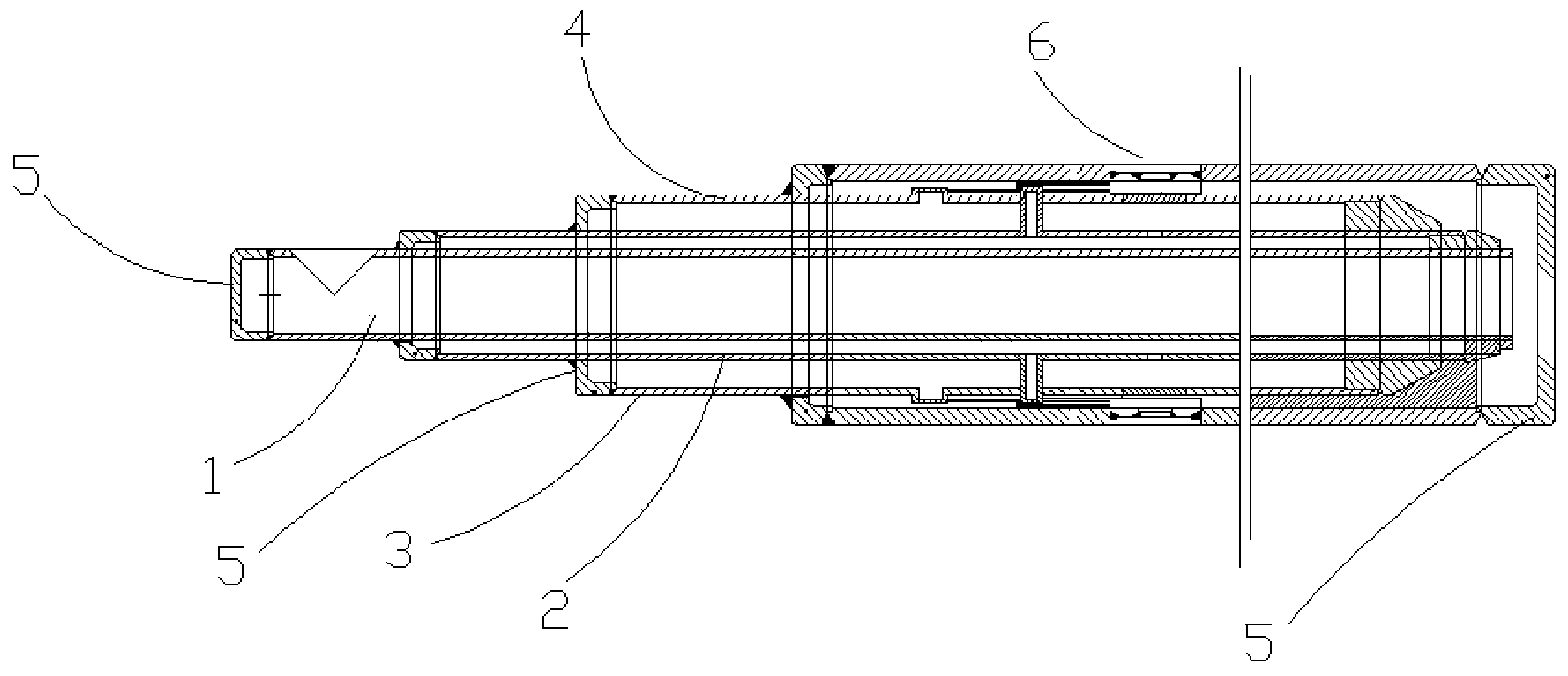

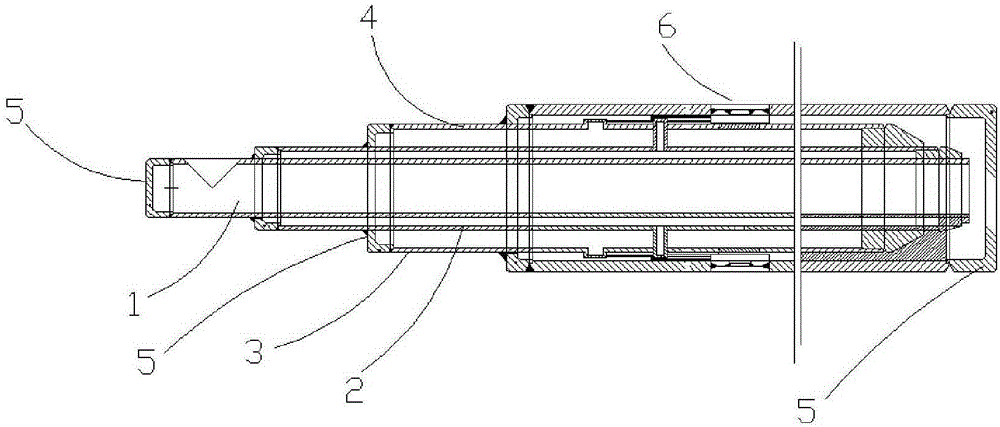

Improved type desulfurization and denitrification spray gun

InactiveCN104001418AReduce manufacturing costExtended service lifeDispersed particle separationEngineeringElectrical and Electronics engineering

The invention discloses an improved type desulfurization and denitrification spray gun which comprises a first tube, a second tube, a third tube and a fourth tube which are arranged in sequence from inside to outside and are connected at intervals through support rings, wherein one end of the first tube is blocked by an end plug for sealing; a through hole is formed in the other end of the first tube; the part between each of two ends of the second tube and the outer wall of the first tube is sealed by using an end seal; the part between each of two ends of the third tube and the outer wall of the second tube is sealed by using an end seal; the part between one end of the fourth tube and the outer wall of the third tube is sealed by using another end seal; the other end of the fourth tube is sealed by using another end seal; a plurality of nozzle components which are arranged at intervals in the radial direction and the axial direction are arranged on the wall of the fourth tube; a plurality of second connectors which face outwards are formed on the wall of the second tube; the second connectors penetrate through the wall of the third tube; urea tubes are arranged among the second connectors and the nozzle components; a plurality of convex third connectors are formed on the wall of the third tube; air tubes are arranged among the third connectors and the nozzle components. By adopting the spray gun, the desulfurization and denitrification working efficiency is improved, meanwhile the service life is prolonged, and the use cost is lowered for companies.

Owner:姜建勇

Spray head special for desilting of urban underground pipeline

InactiveCN110206132ANo violent collisionReduce flow lossSewer cleaningSpray nozzlesEngineeringHigh pressure water

The invention relates to the technical field of desilting of underground pipelines, in particular to a spray head special for desilting of an urban underground pipeline. The problems that the flow velocity loss of high-pressure water inside an existing spray head is large, a spraying water column is dispersed after being sprayed into the inner wall of the underground pipeline, spraying strength isinsufficient, and consequently, the cleaning effect is poor are solved. According to the spray head, a flow diversion channel is formed to be annular, the section of the flow diversion channel is semicircular, the flow diversion channel is in smooth transition connection with a water gathering channel, the center of the flow diversion channel is protruded towards the water gathering channel alongthe axis of a balance weight head to form a flow diversion cone head, thus high-pressure water entering through a water pipe joint can be subjected to flow diversion at the flow diversion cone head,the direction of the high-pressure water is smoothly changed through the semicircular flow diversion channel and the water gathering channel in smooth transition connection with the flow diversion channel, the high-pressure water does not acutely collide with the water gathering channel and the flow diversion channel, and the flow velocity loss of the high-pressure water is reduced effectively. The spray head is mainly used for desilting of the urban underground pipeline.

Owner:常州市捷甲非开挖管道技术有限公司

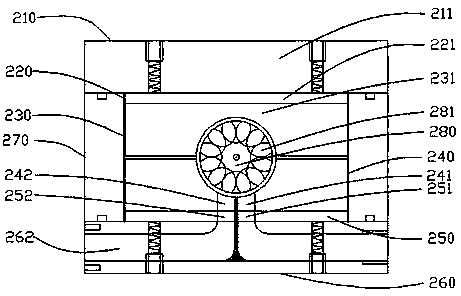

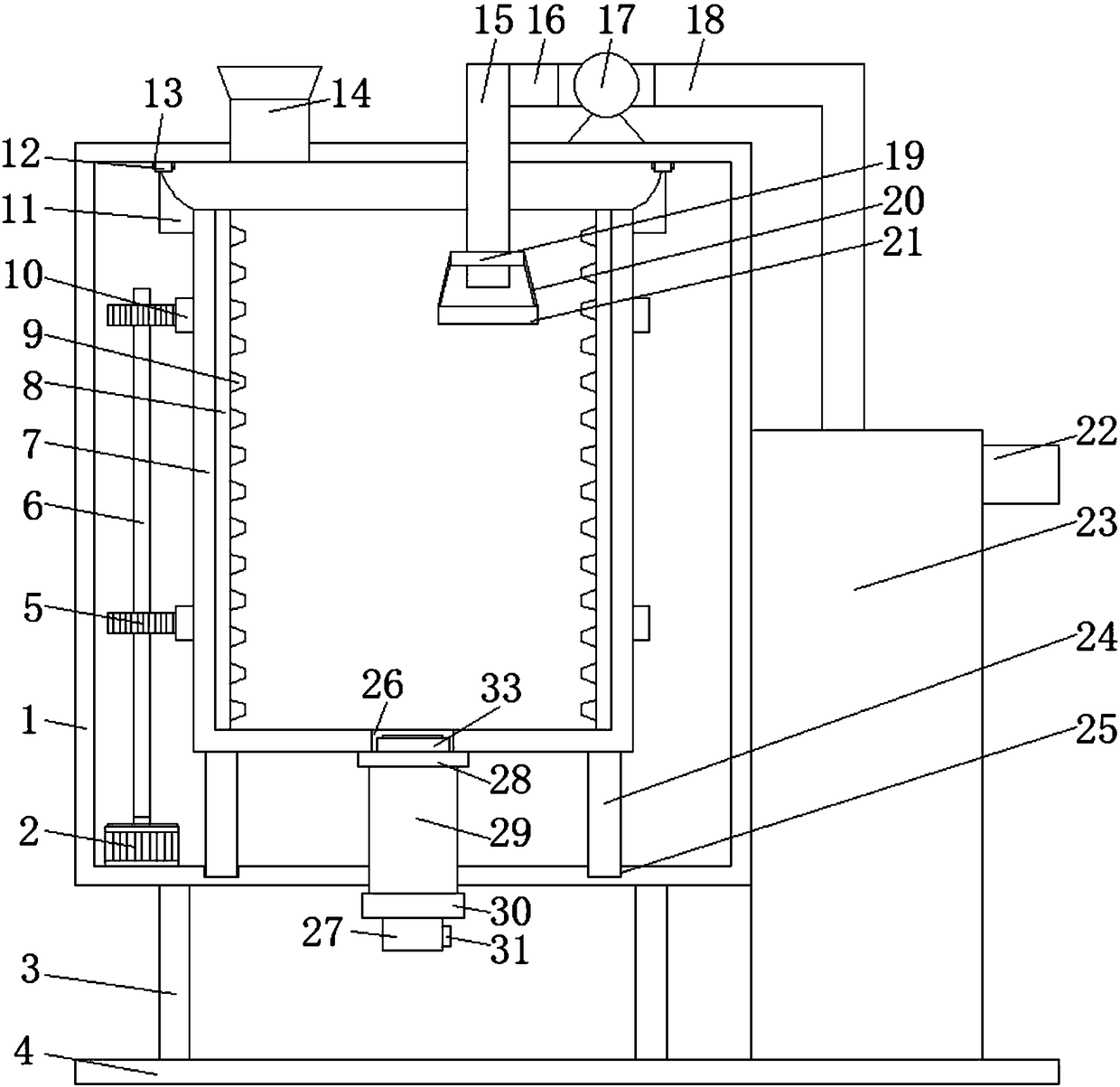

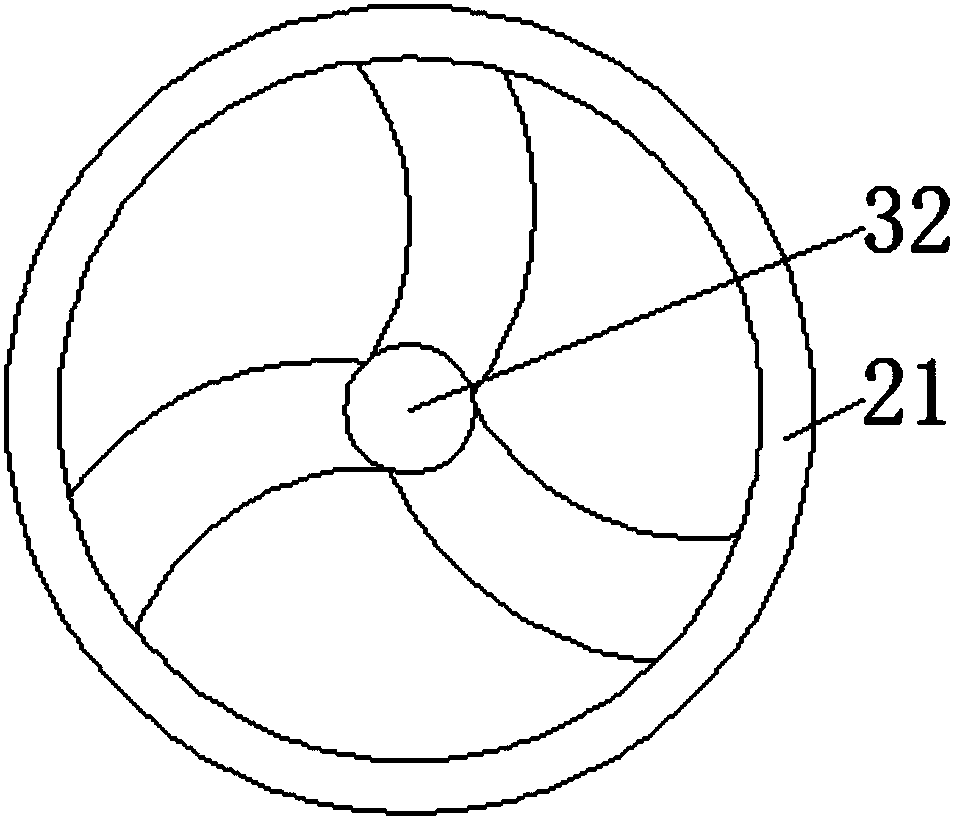

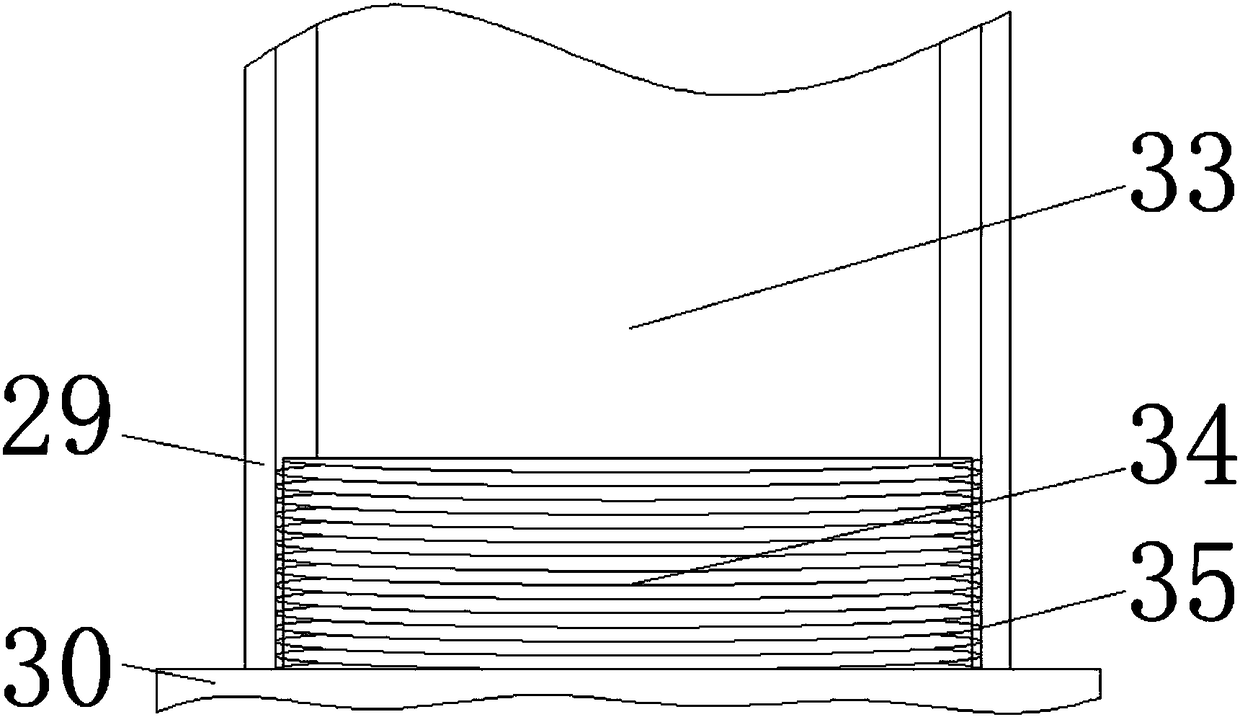

Quenching furnace

InactiveCN102690933AAvoid accessImprove quenching qualityQuenching devicesQuenchingMaterials science

The invention discloses a quenching furnace, which comprises a hearth, and a blanking channel which is arranged at a discharge end of the hearth and is communicated with a quenching groove; wherein an oil curtain mechanism is arranged between the lower part of the blanking channel and the quenching groove and comprises an oil curtain chamber, the upper end of the oil curtain chamber is communicated with the blanking channel and the lower end of the oil curtain chamber is communicated with the quenching groove; an oil injection pipe which transversely extends and an arc-shaped oil curtain plate which is positioned below the oil injection pipe are respectively arranged on two opposite side walls of the oil curtain chamber; a plurality of nozzles facing towards the arc-shaped oil curtain plate are formed on the oil injection pipe and are axially distributed along the oil injection pipe; and the arc-shaped oil curtain plate is arched downwards and extends towards the blanking channel. Theinvention provides the improved oil curtain mechanism on the basis of related patents, a large amount of steam and a large amount of oil smoke in the quenching groove are effectively prevented from entering the hearth, the problem that an oil duct is frequently blocked is solved, and the maintenance cost of equipment is saved.

Owner:苏州工业园区热处理设备厂有限公司

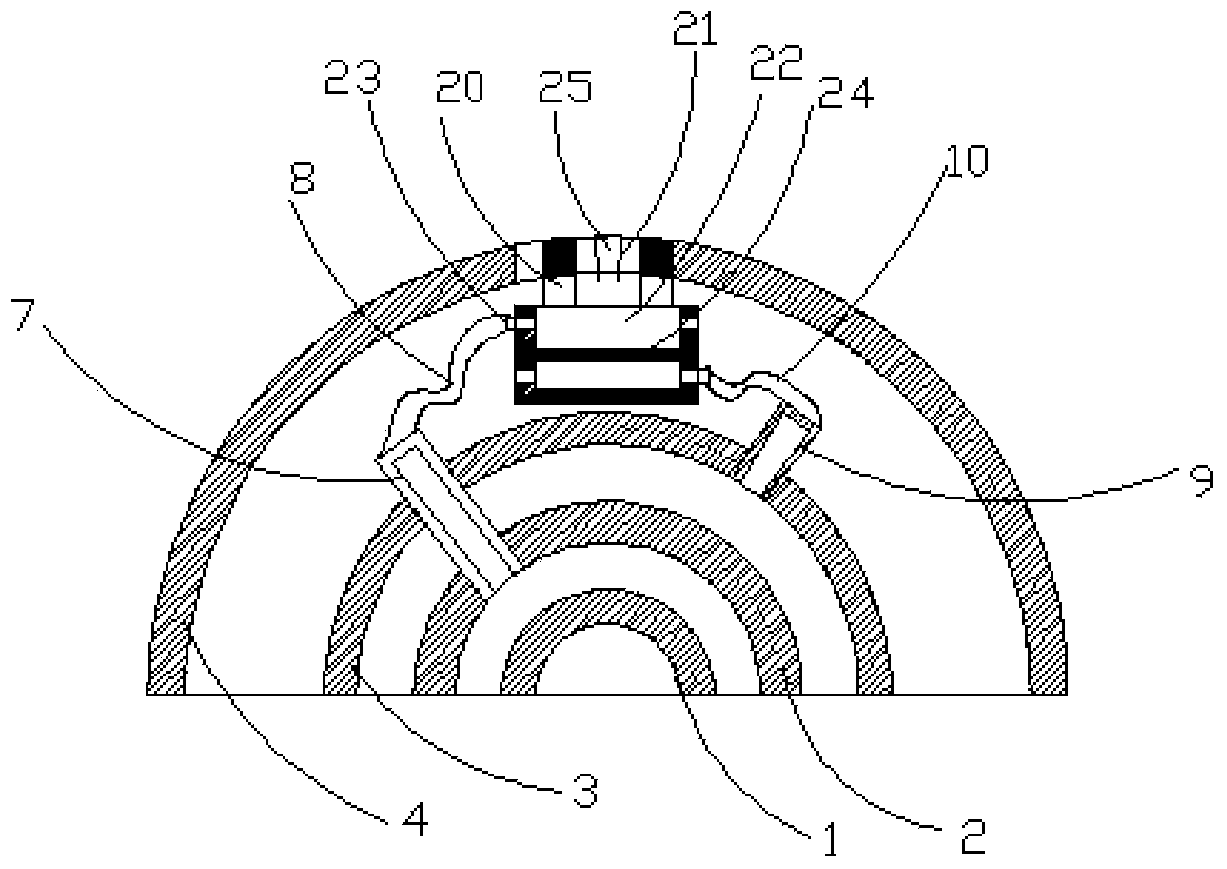

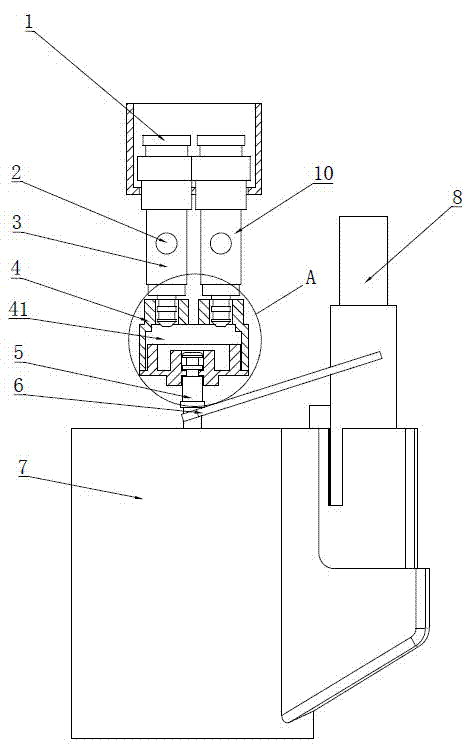

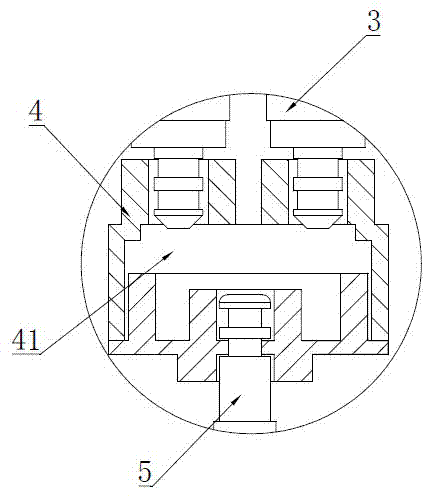

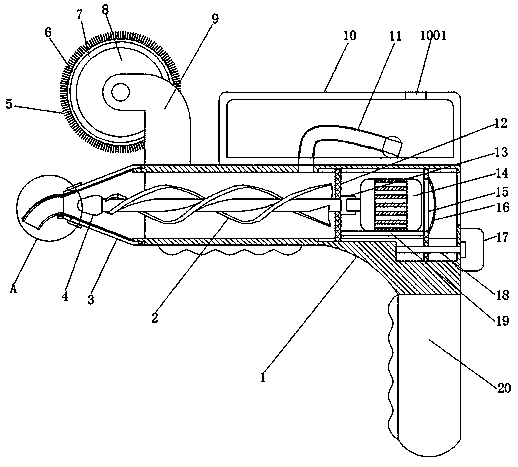

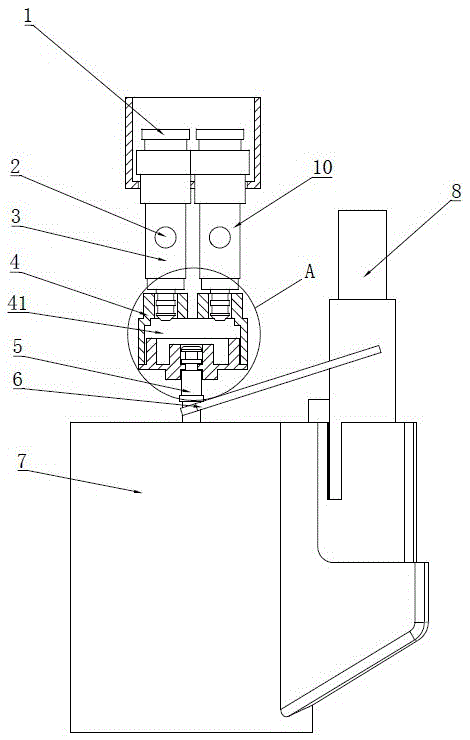

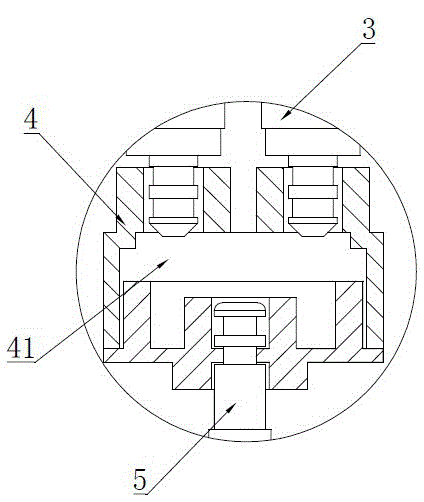

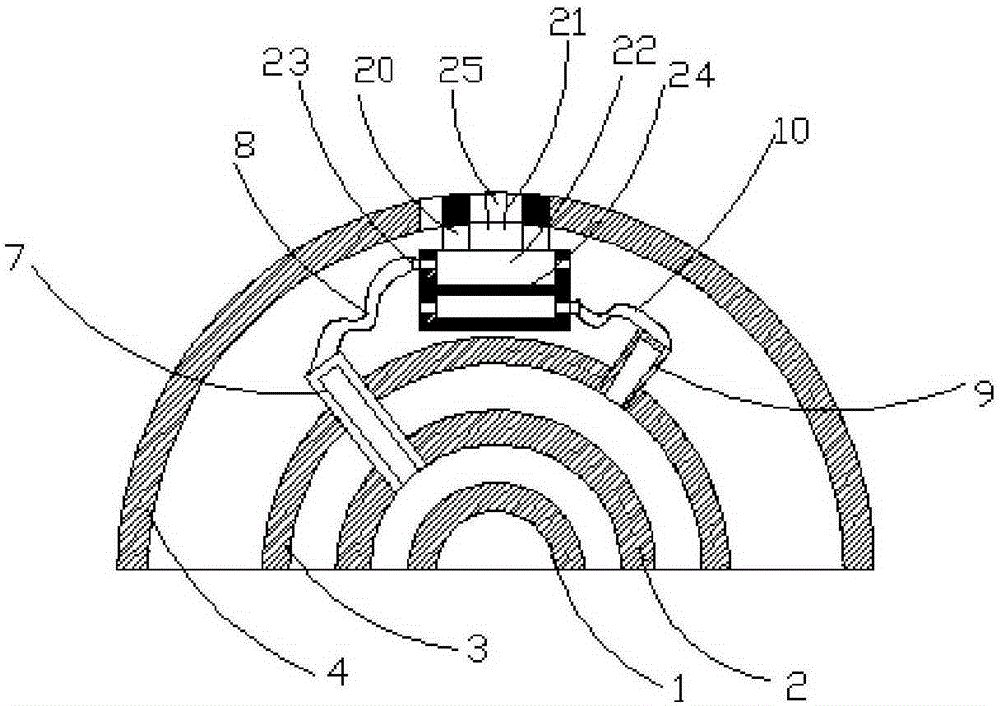

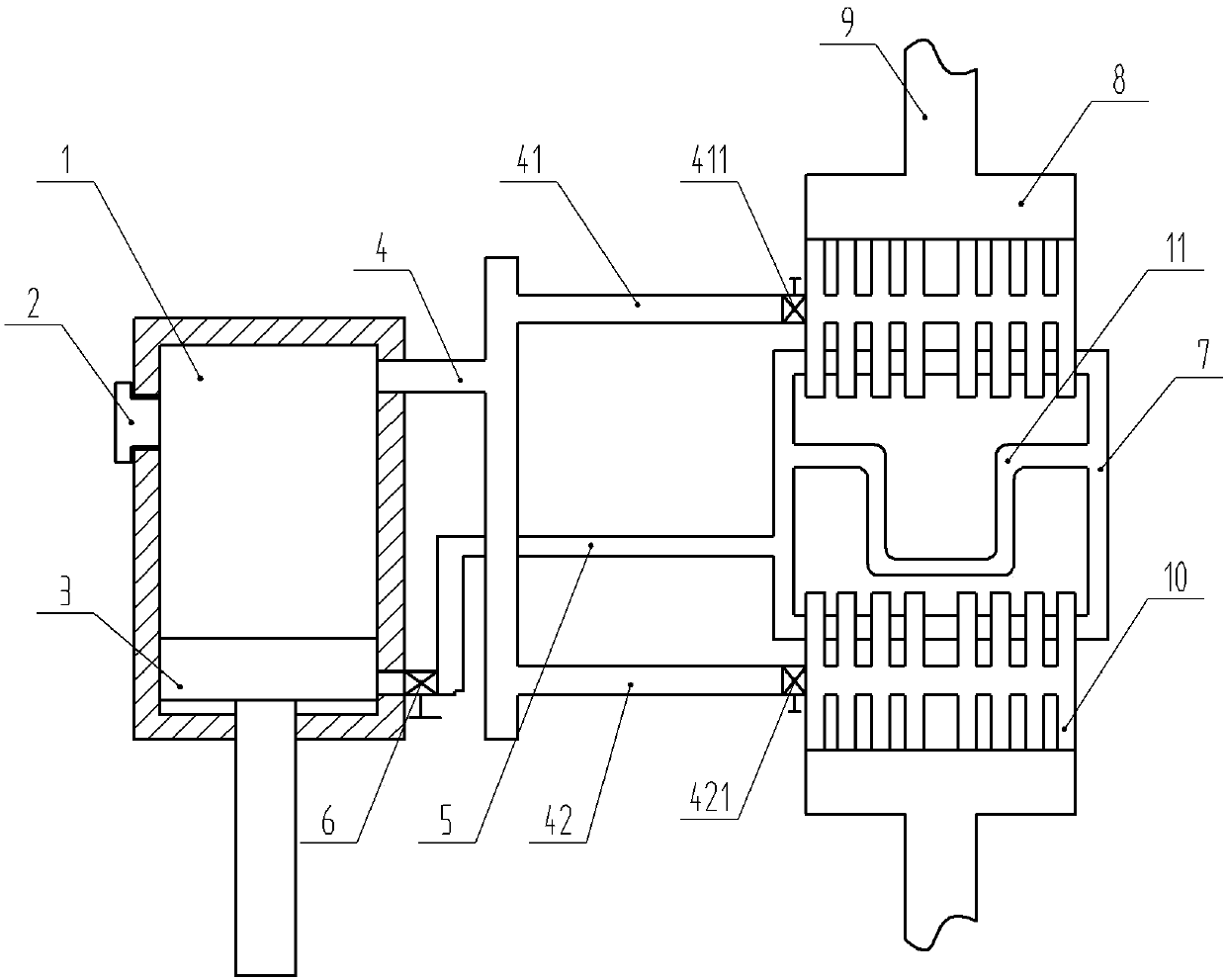

Multi-flame lighter

ActiveCN103486609AImprove atomization effectIncrease the spray forceFuel lightersEngineeringGas supply

The invention relates to a multi-flame lighter, which mainly solves the problems of complex structure, weak flame strength and high manufacturing cost existing in the conventional lighter in use. At least two groups of flame components (10) are arranged; a splitter (4) is hermetically connected between the flame components (10) and a gas outlet valve (5); a gas atomization chamber (43) is arranged in the splitter (4); the upper end of the splitter (4) is provided with a gas outlet (41) which is connected with a gas supply pipeline (3), and the lower end of the splitter (4) is provided with a gas inlet (42) which is connected with the gas outlet valve (5). The multi-flame lighter has the characteristics of simple structure, uniform lighting and stable flame strength.

Owner:WENZHOU JONBON SMOKING SETS MANUFACTRUING CO LTD

Graphene film cutting equipment

InactiveCN113001782AAvoid Scratching SituationsCase that won't scratchWorking accessoriesCleaning using gasesThin membraneEngineering

The invention discloses graphene film cutting equipment which structurally comprises a main body, a box door and a control panel. The box door is arranged at the front end of the main body, the control panel is installed at the front end of the top of the main body, the main body comprises an air inlet pipe, a cutting table, a cutting block and a chip collecting box, and the cutting table comprises a vent groove, a pull rod, a guide block, a turnover device, an air injection device and a discharging pipe; the turnover device comprises a movable groove, a supporting plate, an upper ejector rod and an air injection groove; the movable groove comprises a groove body, an air guide block, a supporting frame and a supporting strip; and the supporting strip comprises an air guide sheet, an air outlet hole and a filter screen. According to the graphene film cutting equipment, the guide block is driven by the pull rod to move forwards, so that the turnover device can drive a graphene film to be inclined, airflow can fully impact carbon powder on the end surface of the film, the carbon powder is guided into the discharging pipe, the carbon powder can fall into the chip collecting box to be collected, the carbon powder is prevented from being attached to the end face of the thin film due to static electricity, and the situation that the thin film is scratched during storage is avoided.

Owner:鄢丽媛

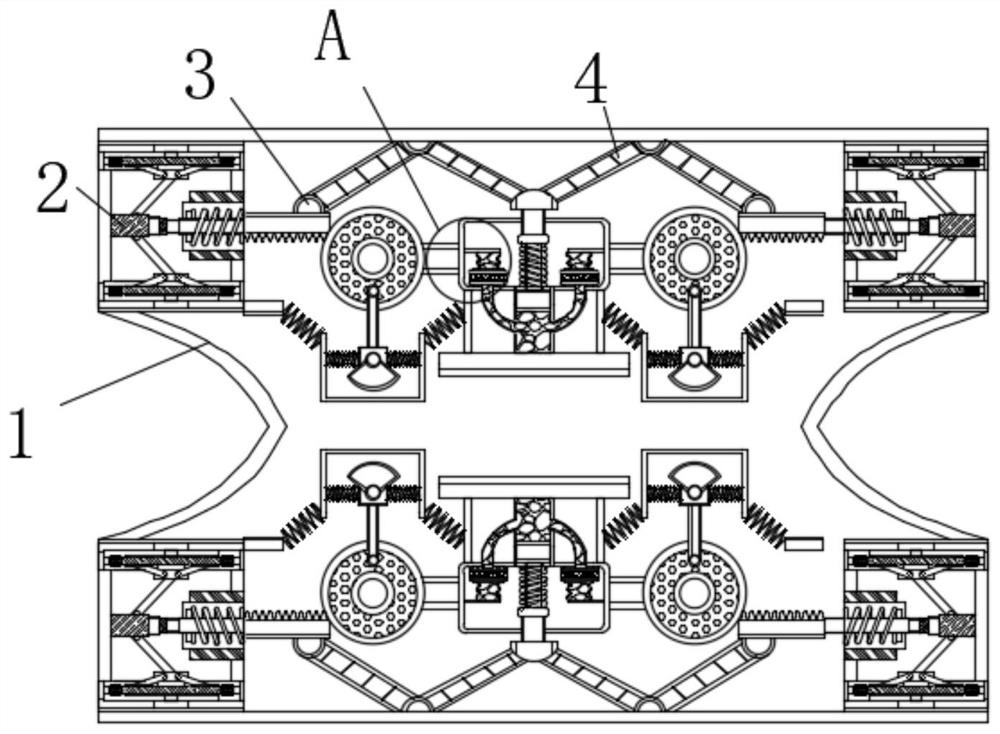

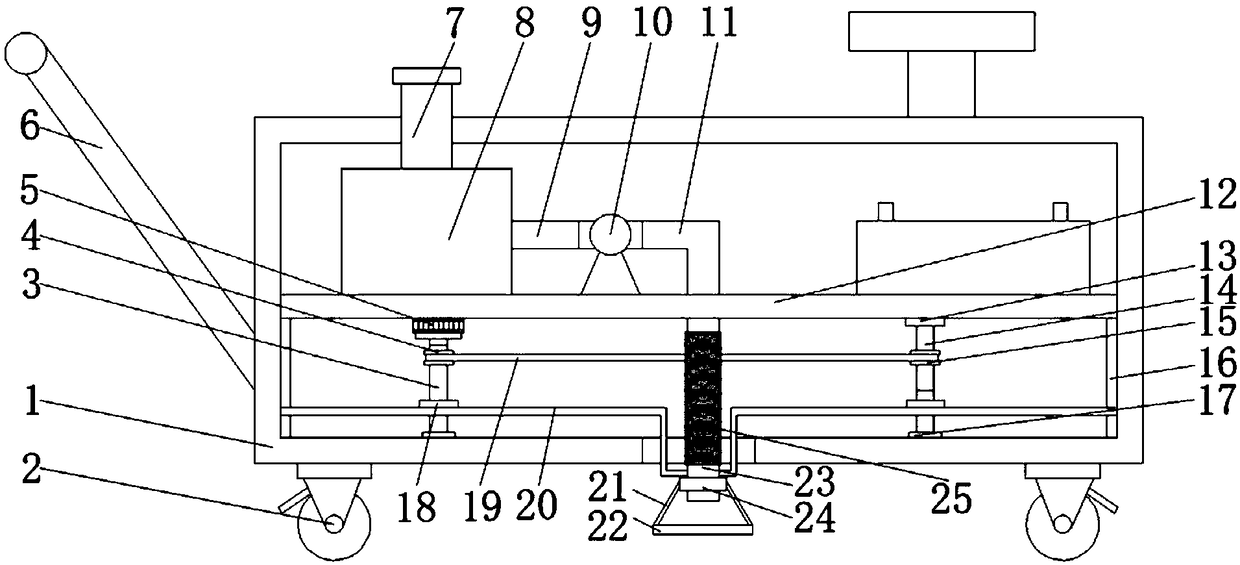

Rubber part freezing trimming device based on 3D (three-dimensional) imaging and work method thereof

A rubber part freezing trimming device based on 3D (three-dimensional) imaging comprises a bottom seat, a support leg, a case, a pill spray device, a refrigerating device, a motor frame, a drive motor, a screw rod, a clamp, a 3D imaging system, an upper computer, a cover body and a lifting piston, wherein the cover body and the lifting piston are arranged in the case, the cover body comprises a pill storage layer, a cold storage layer and a spray layer which are sequentially arranged from the outside to the inside, a plurality of inner spray heads and a plurality of outer spray heads are arranged in the spray layer, a first valve is arranged on each inner spray head, a second valve is arranged on each outer spray head, the pill spray device communicates with the pill storage layer througha first hose, the refrigerating device communicates with the cold storage layer through a second hose, the 3D imaging system comprises a 3D camera, a laser probe, a 3D processing module and an imagingmodule, and the upper computer is respectively connected with the 3D imaging system, the drive motor, the pill spray device, the refrigerating device, the lifting piston, the first valves on the plurality of the inner spray heads and the second valves on the plurality of the outer spray heads. The rubber part freezing trimming device based on the 3D imaging significantly improves trimming efficiency of a rubber part.

Owner:东莞市博铨橡塑有限公司

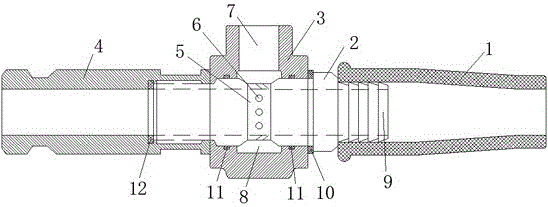

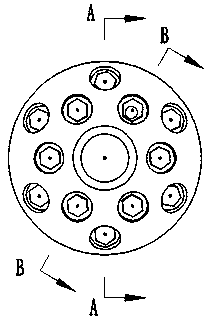

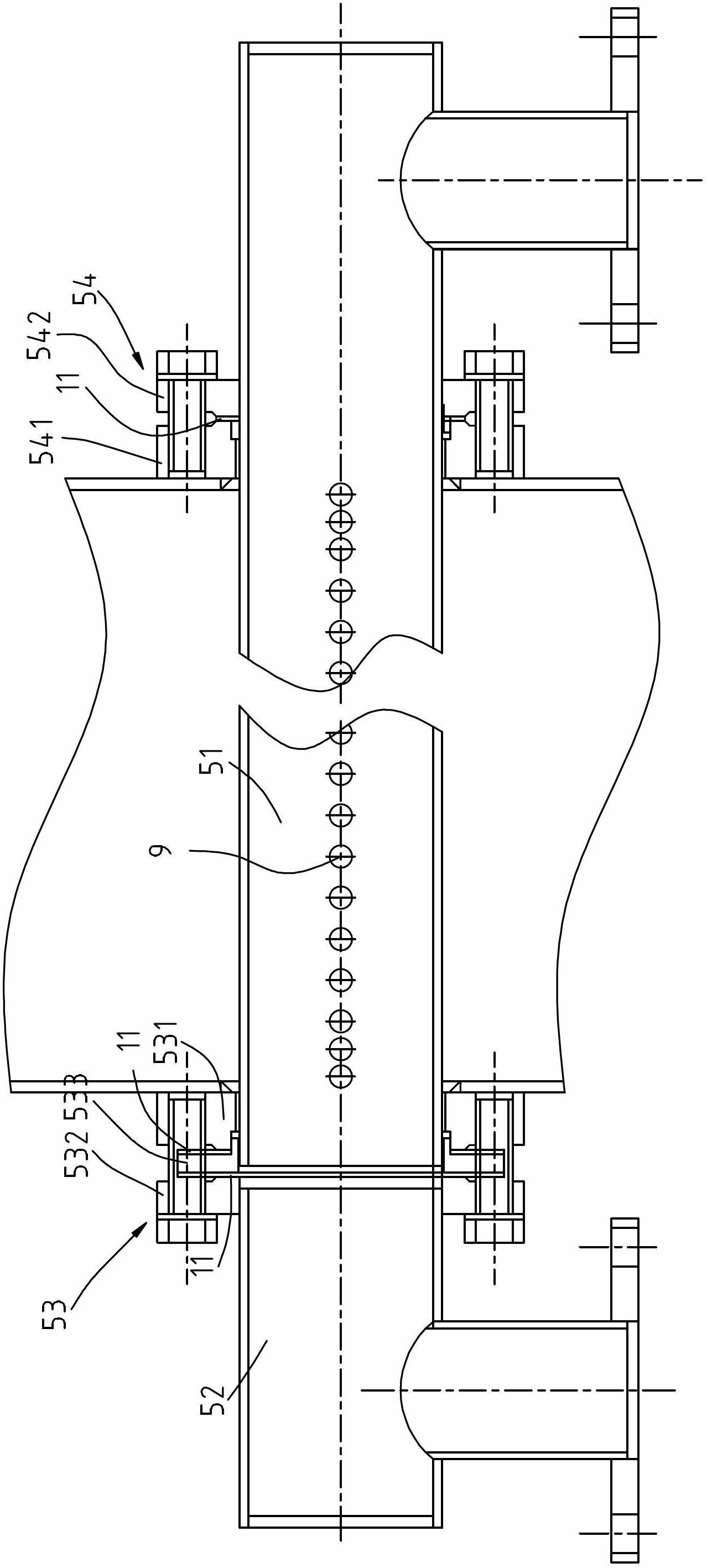

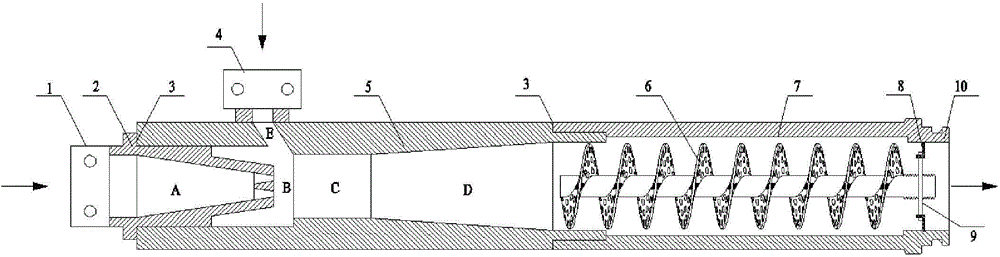

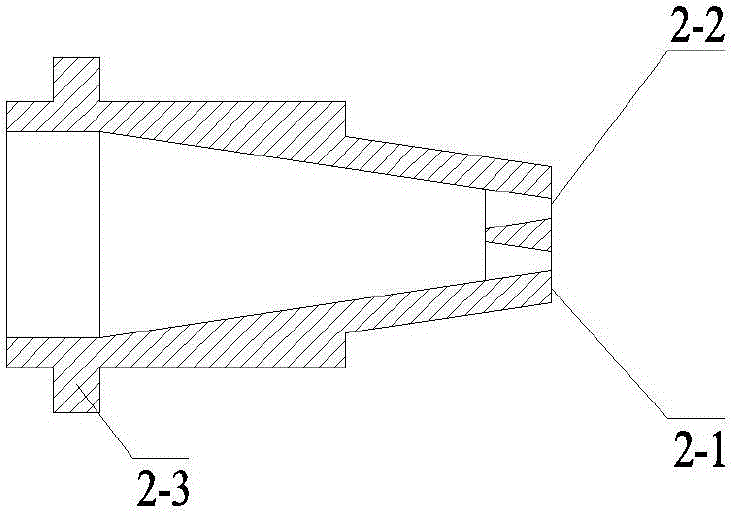

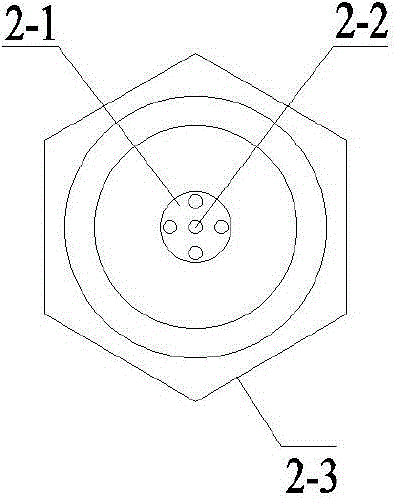

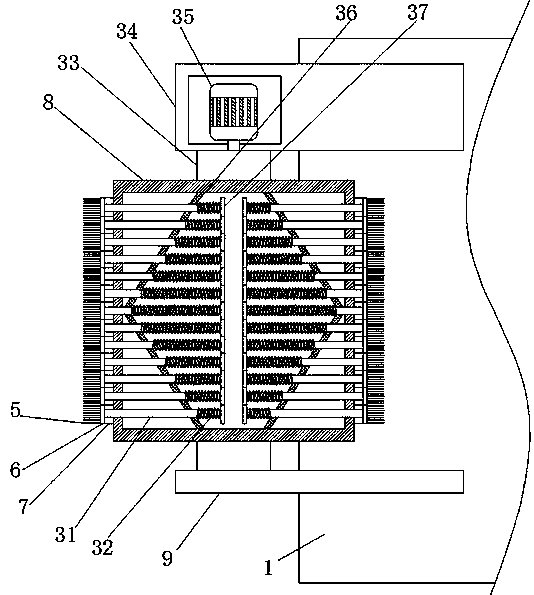

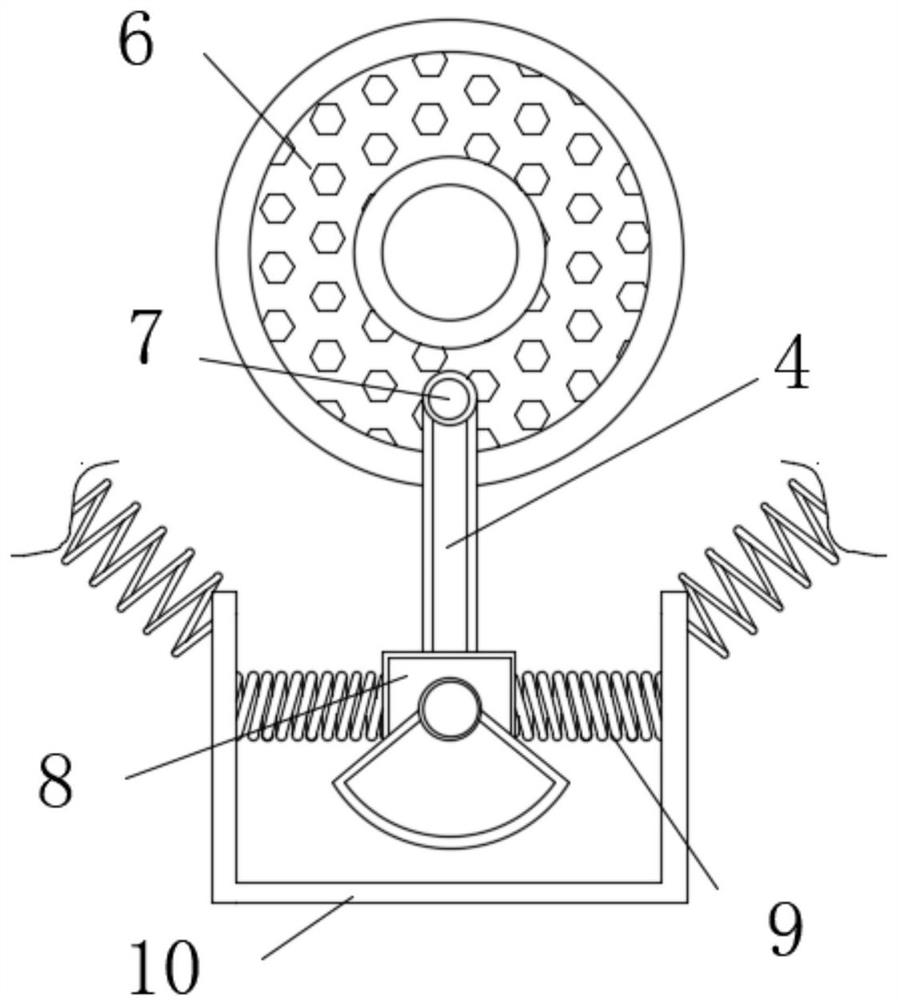

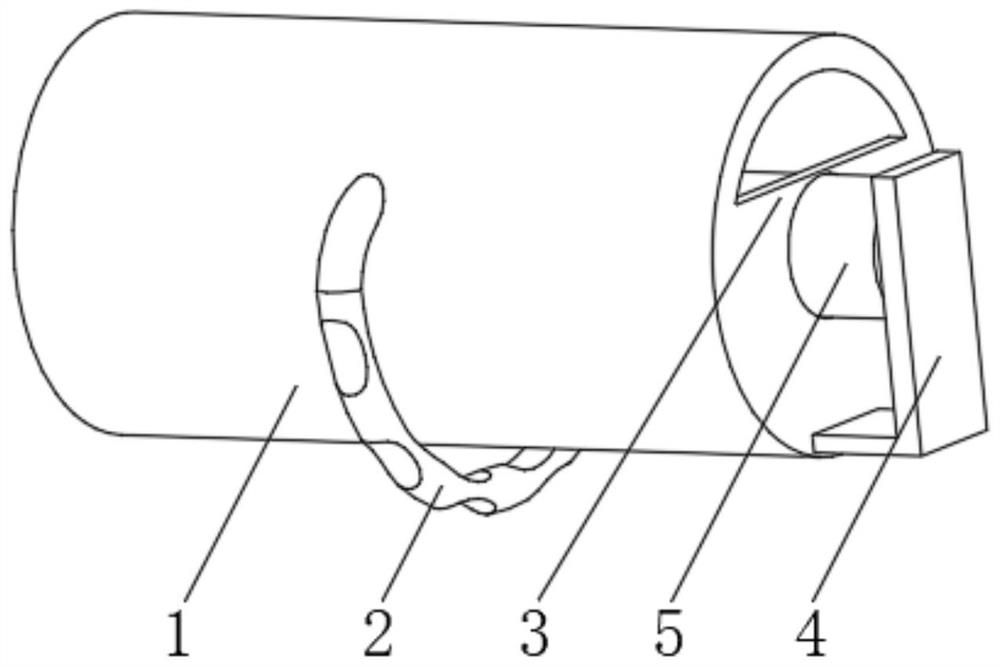

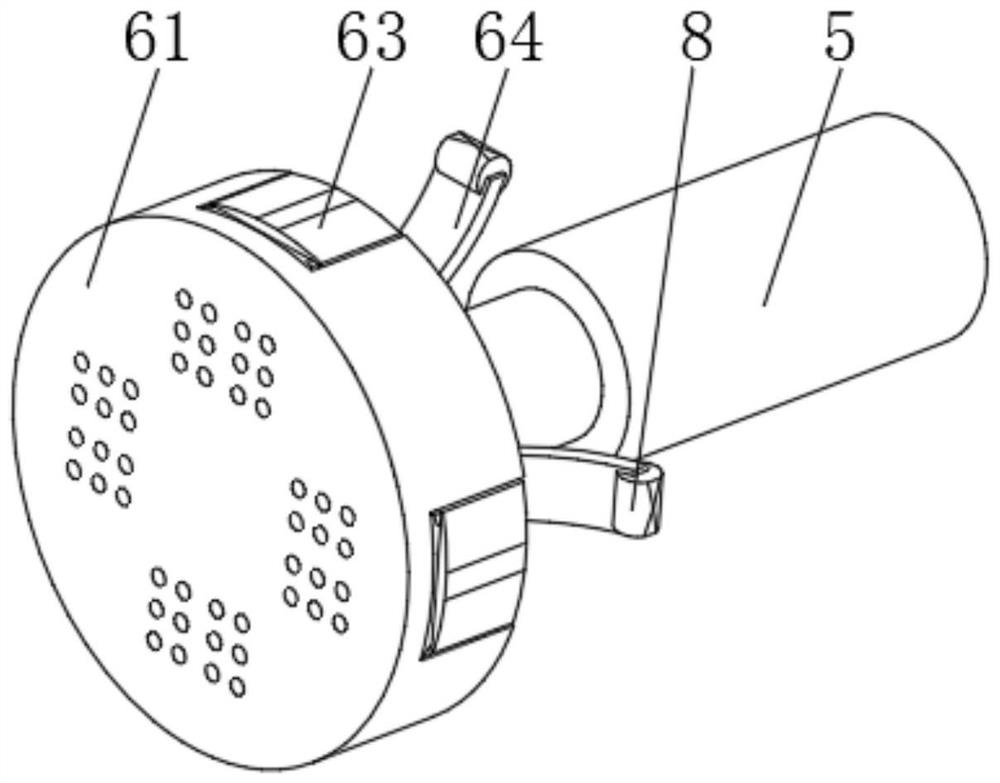

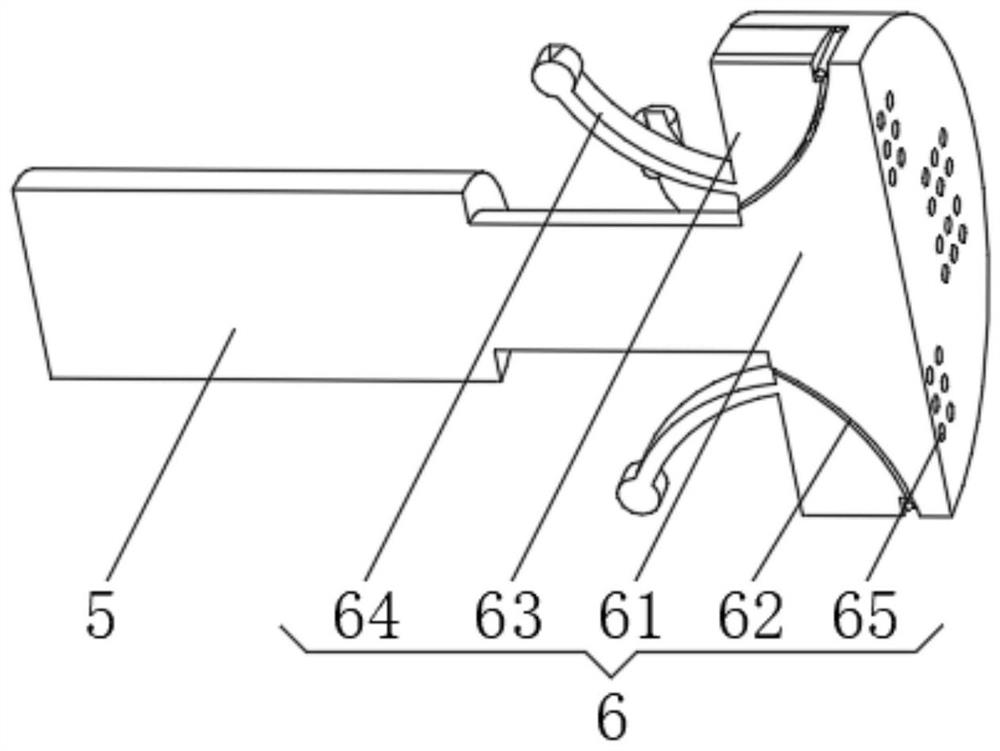

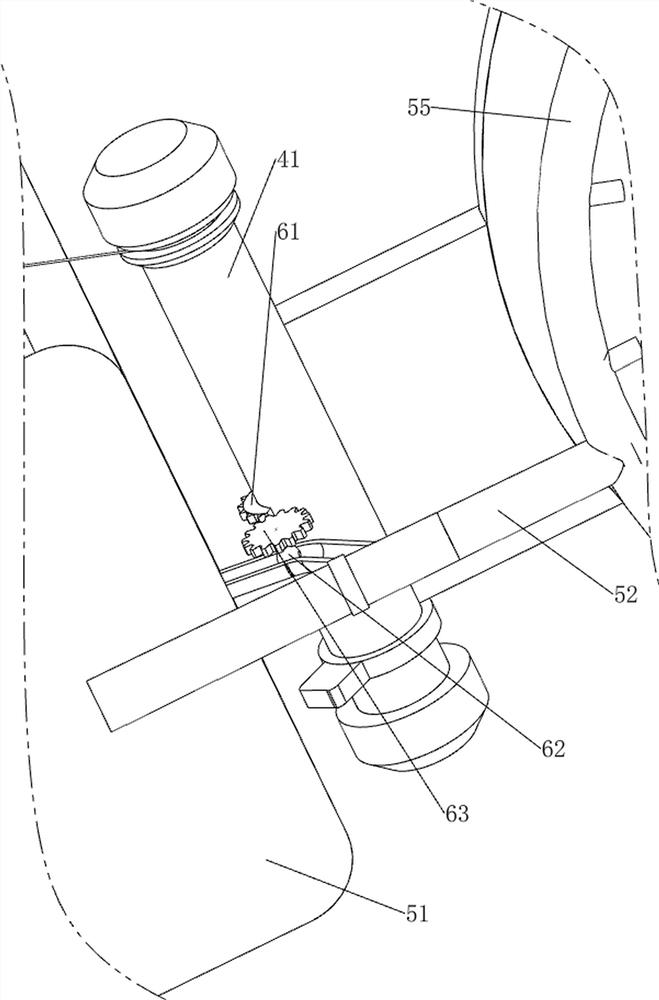

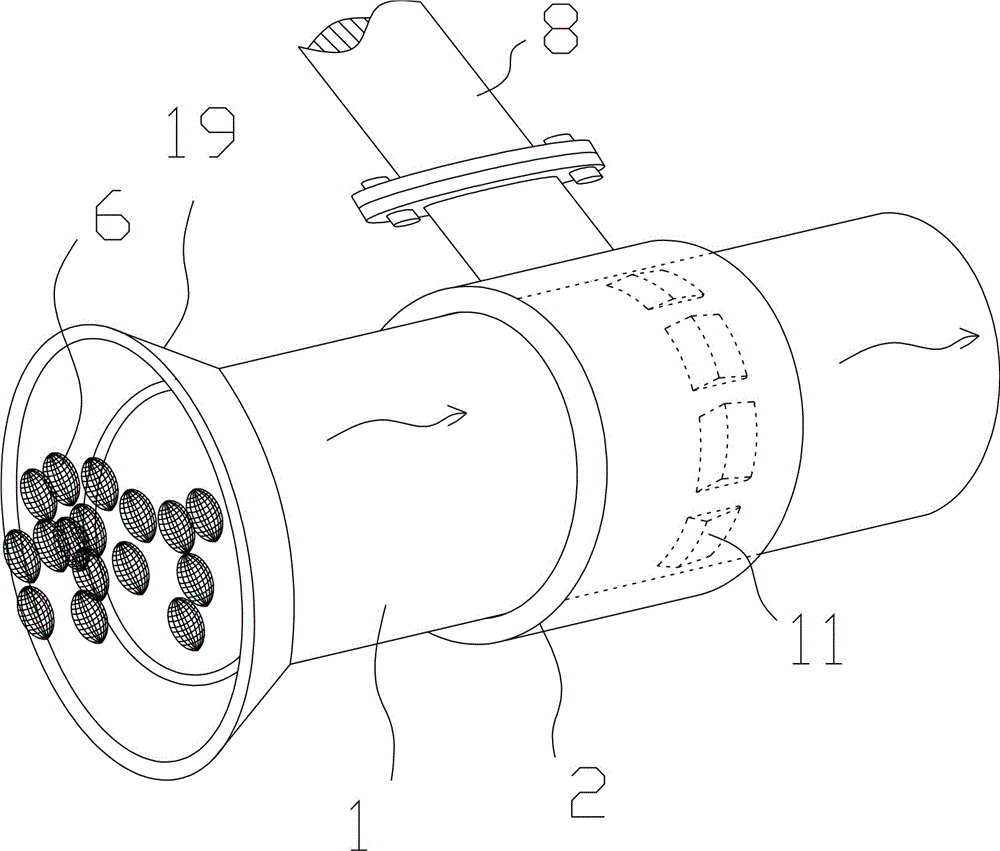

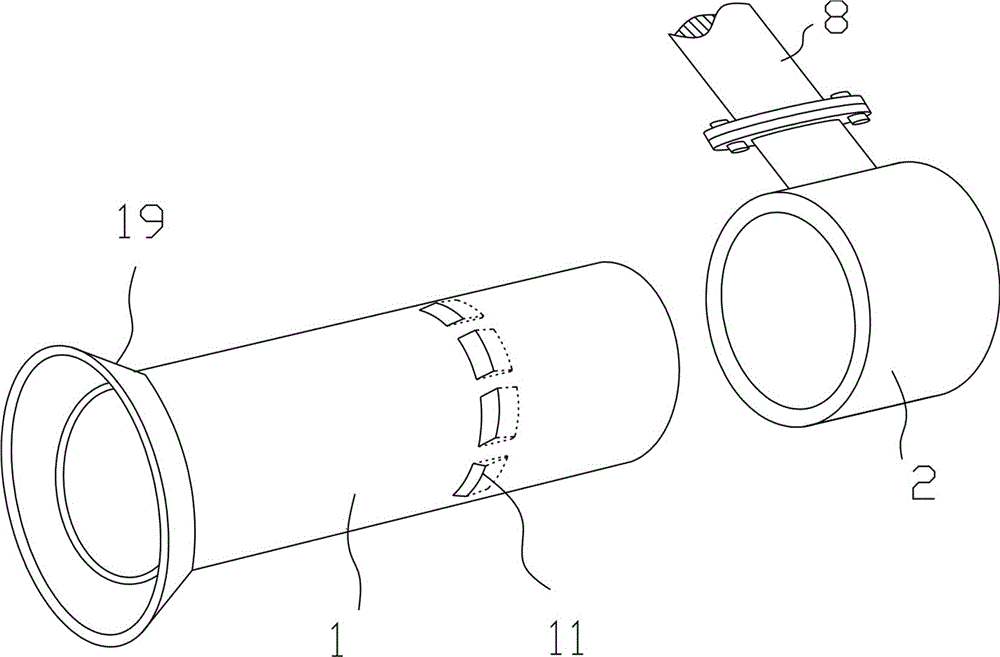

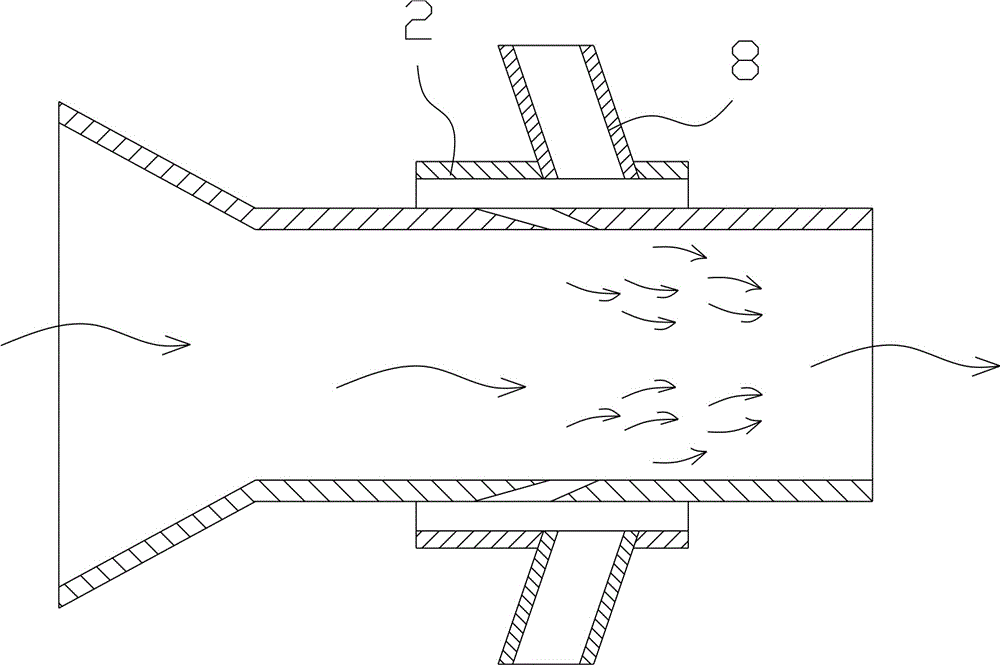

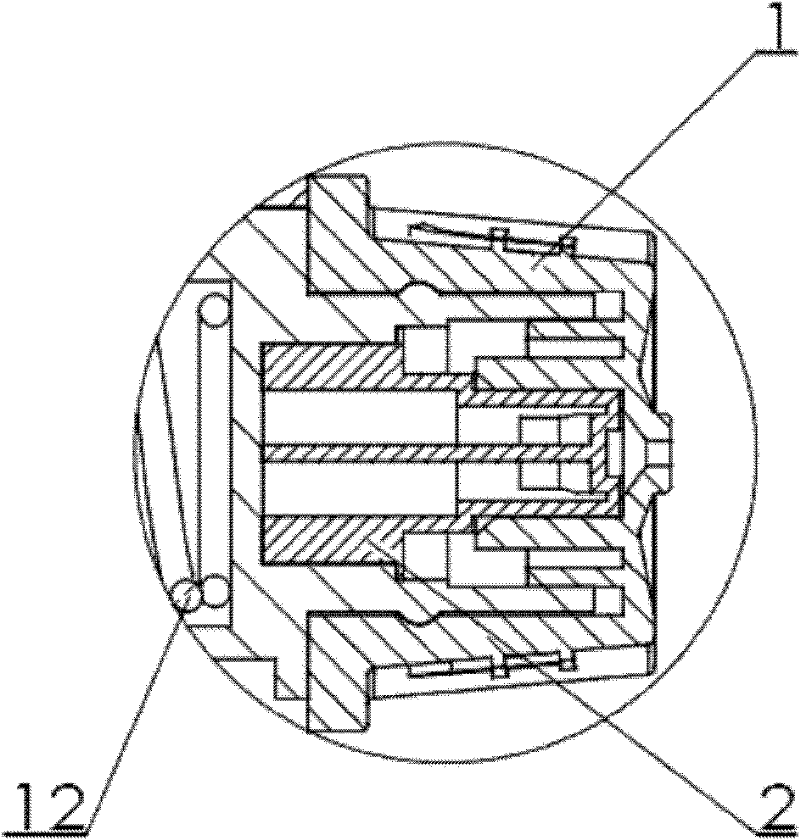

A mine-used porous spiral foam generating device

The invention discloses a mining porous spiral-type foam generating device. The mining porous spiral-type foam generating device comprises a compressed air joint (1), a nozzle body (2), a gas-liquid mixing chamber (5), porous spiral-type foamers (6), a foaming cylinder body (7) and a foam outlet joint (10), wherein the rear end of the nozzle body (2) is provided with at least one outlet nozzle; a nozzle cavity in the nozzle body (2) is of a circular truncated cone contracted shape; the compressed air joint is connected with the nozzle body; the nozzle body is installed at the inner side of the front end of the gas-liquid mixing chamber; the porous spiral-type foamers are installed in the foaming cylinder body. A multi-nozzle jet flow structure provided by the invention can achieve low-resistance high-efficiency mixing of a gas phase and a liquid phase. A wire surface high-multiple foaming and spiral low-resistance high-efficiency heat transfer mass transfer coupling mechanism is adopted for foaming, so that the foaming performance of the device is improved greatly; the generated foam is low in wind to foam ratio, is high in foaming quantity and is high in foam forming ratio; the resistance loss in the mixing and foaming process is reduced; the driving pressure of the device is improved; easily damage moving components in a turbulent flow foaming device are discarded; the device foaming reliability is improved.

Owner:CHINA UNIV OF MINING & TECH +1

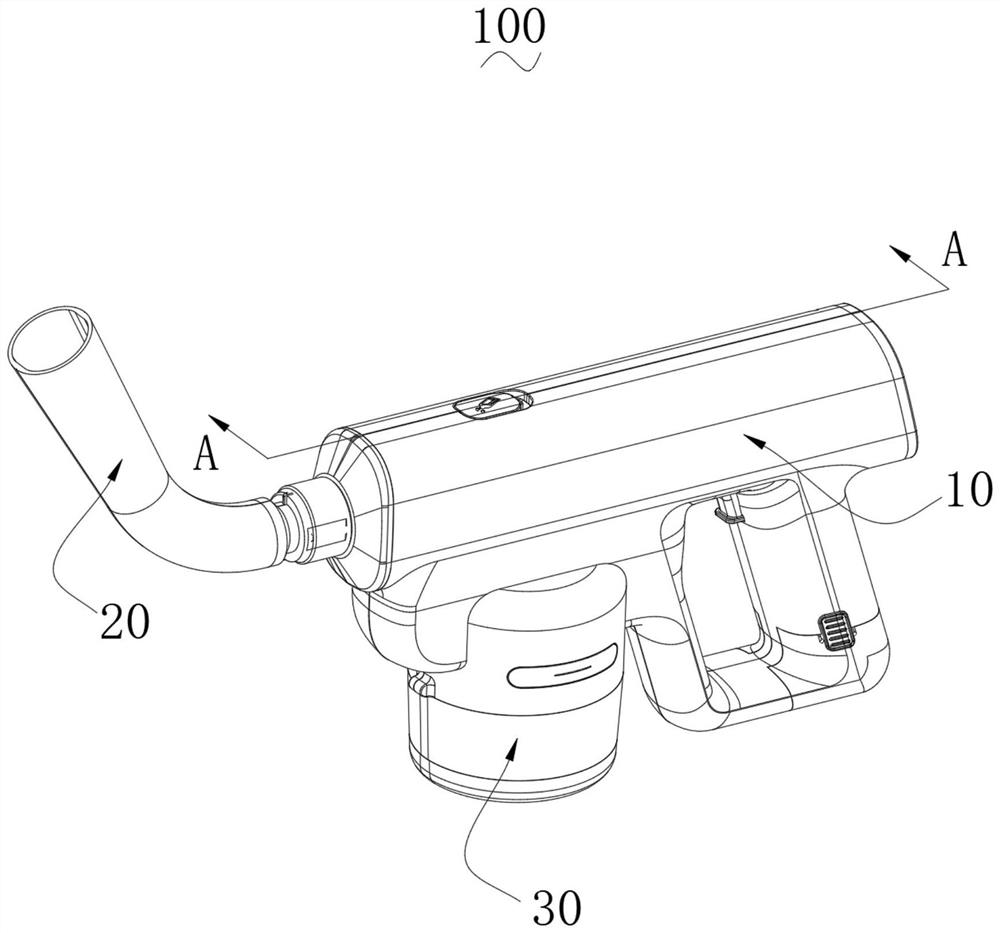

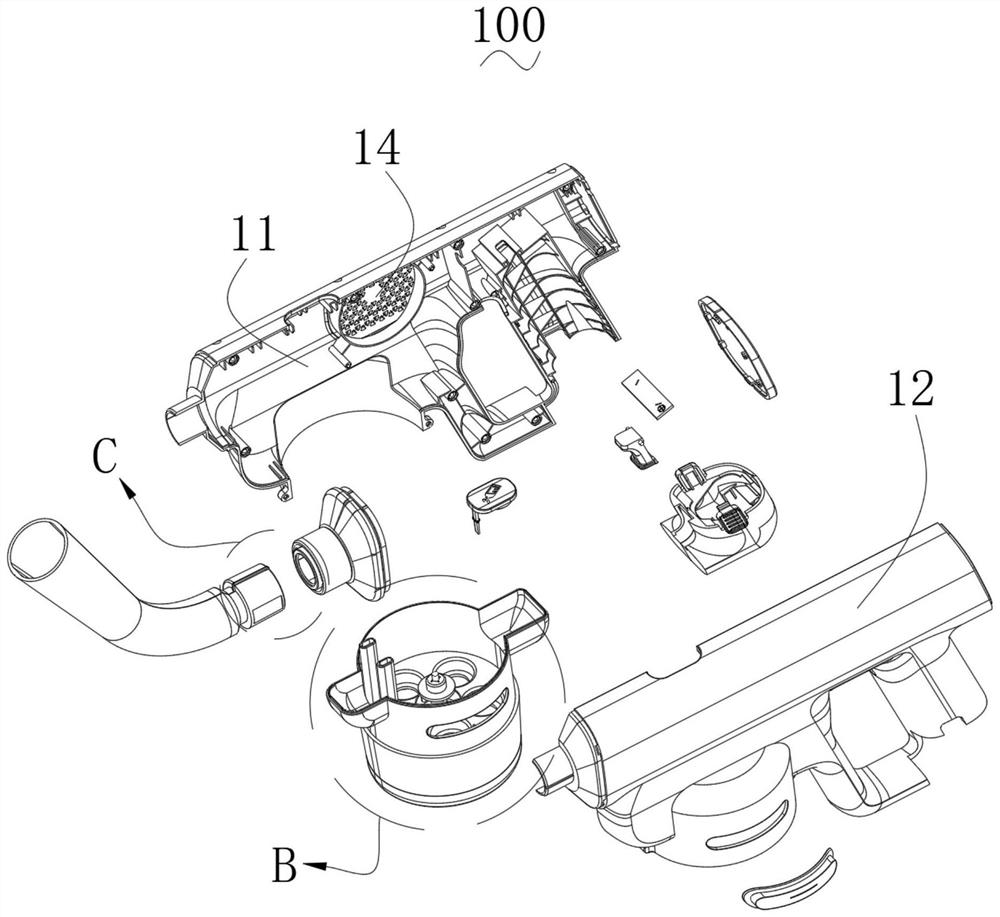

Special spray gun for photocatalyst

ActiveCN113231220BIncrease the spray forceSmall particlesLiquid spraying apparatusMechanical engineeringElectrical and Electronics engineering

The invention discloses a special spray gun for photocatalyst, which comprises a gun body with accommodating space, a gun head detachably connected with the gun body, a photocatalyst refinement assembly detachably connected with the gun body, a driving part and a power supply. The gun body includes a first housing and a second housing that are symmetrically arranged and assembled with each other, and a partition that connects the first housing and the second housing, and the partition separates the storage space It is a front chamber and a rear chamber, the photocatalyst refinement assembly and the gun body together form the front chamber, and the front chamber communicates with the gun head, and the driving member and the power supply are accommodated in the In the rear cavity, the drive element communicates with the front cavity, and the power supply is electrically connected to the photocatalyst refinement assembly and the drive element respectively. Compared with related technologies, the special spray gun for photocatalyst provided by the present invention can meet the requirements of nano-scale spraying, more reasonable atomization air duct, more uniform particle size, simple operation and portability.

Owner:广州懿恒空气净化技术有限公司

Speed-controlling spraying device for sealant for construction engineering

The invention belongs to the technical field of construction engineering devices, particularly relates to a speed-controlling spraying device for a sealant for construction engineering, and solves theproblems that the direction of a spray head cannot be adjusted and the flow rate cannot be accurately controlled when the sealant is used. The invention adopts following scheme that the speed-controlling spraying device comprises a main body; a storage box is arranged at the top end of the main body; a first through hole is formed in the middle of the main body; a spiral rod is arranged at firstthrough hole in the main body; a moving body is welded to one end of the spiral rod; and a fixing sleeve is welded to the other end of the spiral rod. A threaded sleeve rotates to push a second elastic sheet to move, and the other end of the second elastic sheet pushes a fixed block to bend a first elastic sheet and a leather tube downwards, so that the direction of the leather tube can be arbitrarily controlled; and a knob enables a threaded rod to drive a moving plate to move, and the moving plate enables the moving body to change the size of the aperture of one side of a rotating body, so that the flow rate of the sealant is controlled conveniently, and at the same time, the spray strength can be improved, and building gaps can be filled with the sealant well.

Owner:深圳市河图建设项目管理有限公司

Improved cleaning device for steel balls

The invention provides an improved cleaning device for steel balls, and relates to the field of mechanical equipment. The improved cleaning device for the steel balls comprises a cleaning device body,supporting legs are fixedly connected to the bottom of the cleaning device body, the bottoms of the supporting legs are fixedly connected with a base plate, the top of the cleaning device body is fixedly connected with a feeding pipe, a sliding groove is formed in the top of the inner wall of the cleaning device body, and rotating columns are connected to the sliding groove in a sliding mode, thetops of the rotating columns are fixedly connected with a cleaning inner cylinder, and the outer surface of the cleaning inner cylinder is fixedly connected with limiting blocks and two racks correspondingly. According to the improved cleaning device for the steel balls, a rotating shaft is driven to rotate through starting of a forward and reverse rotation motor, and drives gears to rotate; andthe gears, the racks, the rotating columns and the sliding groove cooperate with one another for use so that the cleaning inner cylinder can rotate, the rotation of the cleaning inner cylinder drivesthe steel balls which are placed into the cleaning inner cylinder to roll, friction is generated between the steel balls and convex blocks, and then the surfaces of the steel balls are cleaned.

Owner:当涂县金龙凤科技股份有限公司

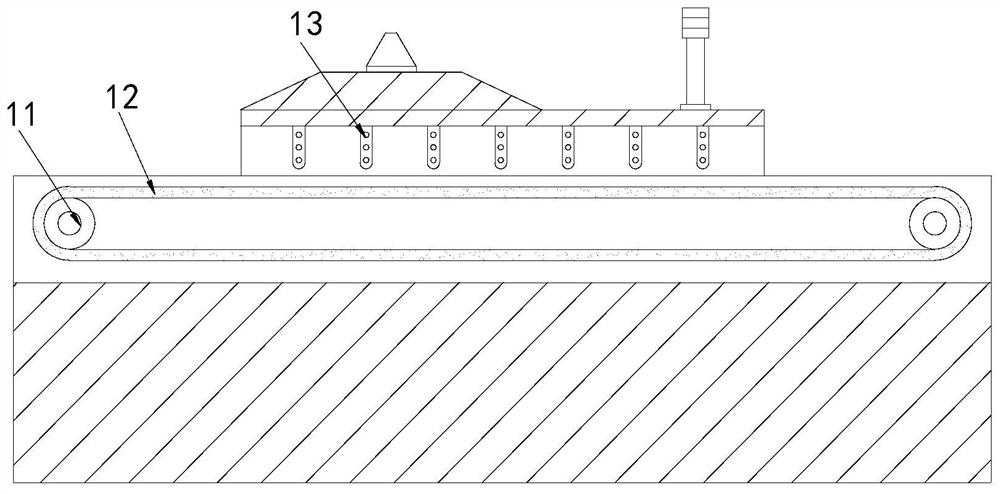

Energy-saving paper box drying equipment

InactiveCN112880329AIncrease the spray forceStrong sprayDrying gas arrangementsPretreated surfacesAdhesiveStructural engineering

The invention discloses energy-saving paper box drying equipment. The energy-saving paper box drying equipment structurally comprises a main body, a control panel and an alarm lamp, the control panel is arranged at the front end of the main body, the alarm lamp is fixedly embedded in the middle of the top of the main body, the main body comprises a rotating shaft, a conveying belt and a drying device, and the drying device comprises a ventilation groove, an air inlet, a rotating fan, a heat conduction piece and a side drying device; and the side drying device comprises an air storage tank, an air inlet, a corrugated sheet and an air outlet head, the air outlet head comprises an air outlet groove, a guide plate and an air spraying head, and the guide plate comprises a fixed block, an air guide groove and an air collecting block. According to the drying equipment, the position of the corrugated sheet in the side drying device is arranged to be aligned with the air outlet head, so that air flow can flow on the end face of the corrugated sheet back and forth, the jet force of the air flow is increased, the air flow can be transversely blown out from the side drying device, the air flow can enter gaps in a paper box to be in contact with an adhesive, and the adhesive can be rapidly solidified.

Owner:张顺妹

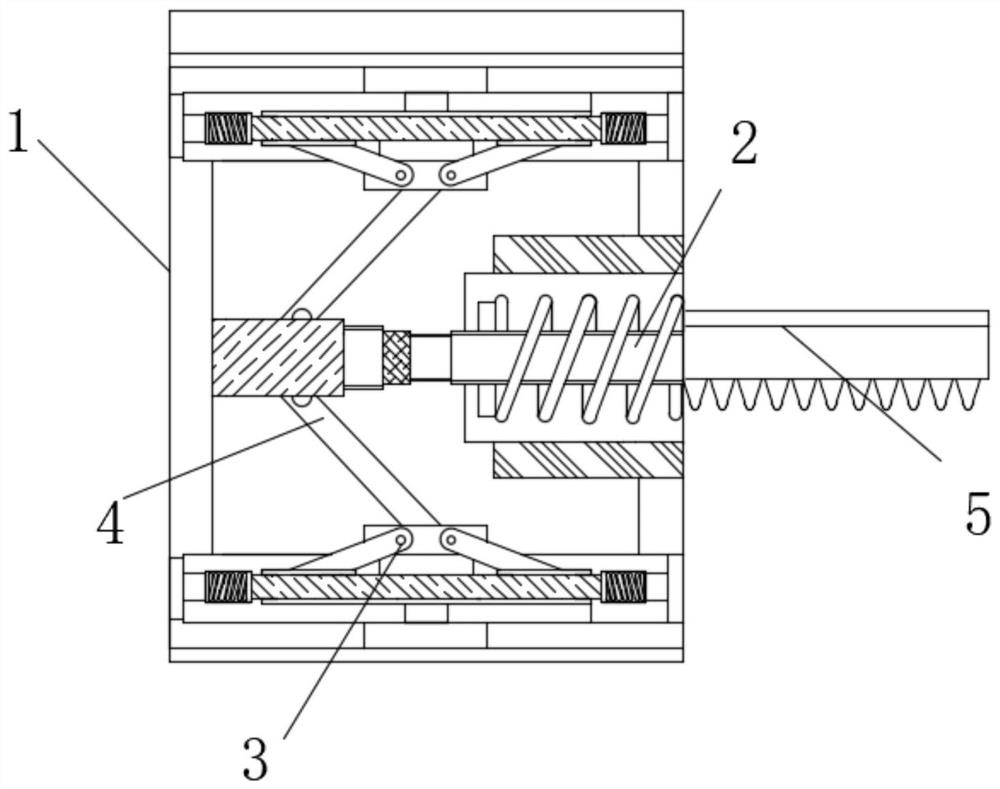

Aluminum alloy formwork dismantling and cleaning equipment

InactiveCN112302343AEasy to handleEnhanced flushingForming/stuttering elementsForm treatmentStructural engineeringManufacturing engineering

The invention relates to the technical field of aluminum alloy formworks, and provides aluminum alloy formwork dismantling and cleaning equipment. The aluminum alloy formwork dismantling and cleaningequipment comprises a machine body. Moving rods are movably connected to the inner walls of the machine body. Pins are movably connected to the outer walls of the moving rods. Linkage rods are movablyconnected to the outer walls of the pins. Rack plates are fixedly connected to the ends, away from the machine body, of the moving rods. The outer walls of the rack plates are movably connected withrotating wheels. According to the aluminum alloy formwork dismantling and cleaning equipment, an aluminum alloy formwork is placed near shocking blocks through a conveying belt, a driving mechanism drives the moving rods to move, the moving rods drive the rack plates to move, the rack plates change the angles of the rotating wheels in a push-pull mode, the rotating wheels and the linkage rods drive vibration blocks to move, vibration springs vibrate when the vibration blocks move, the shocking blocks are affected to vibrate strongly, the shocking blocks vibrate the aluminum alloy formwork, concrete attached to the aluminum alloy formwork is vibrated to be scattered, and the concrete is vibrated to be scattered through vibration so as to be convenient to treat.

Owner:吴忠仁

Furniture paint spraying purification equipment with water treatment device

ActiveCN113731700AShorten the lengthImprove convenienceGas treatmentUsing liquid separation agentStructural engineeringElectric control

The invention discloses furniture paint spraying and purifying equipment with a water treatment device. The equipment comprises an outer purifying cylinder, wherein a holding rod is arranged at the bottom of the outer purifying cylinder, holding grooves are evenly formed in the outer side of the holding rod, a sealing plate is fixedly connected to one side of the outer purifying cylinder, a folding plate is connected to the position, close to the sealing plate, of one side of the outer purifying cylinder, an electric control telescopic rod is connected to one side of the folding plate, one end of the electric control telescopic rod penetrates through the sealing plate and extends into the outer purifying cylinder, and the outer purifying cylinder is provided with a material taking device with a material pushing plate, and a drying device therein. The invention relates to the technical field of furniture paint spraying treatment. According to the furniture paint spraying purification equipment with the water treatment device, the purpose of reducing the equipment size is achieved, the portability degree of the furniture paint spraying purification equipment is improved, the cost of the equipment is reduced, the purification range of the equipment is widened, and meanwhile water on the surface of furniture can be removed.

Owner:诸暨市立挺纺织有限公司

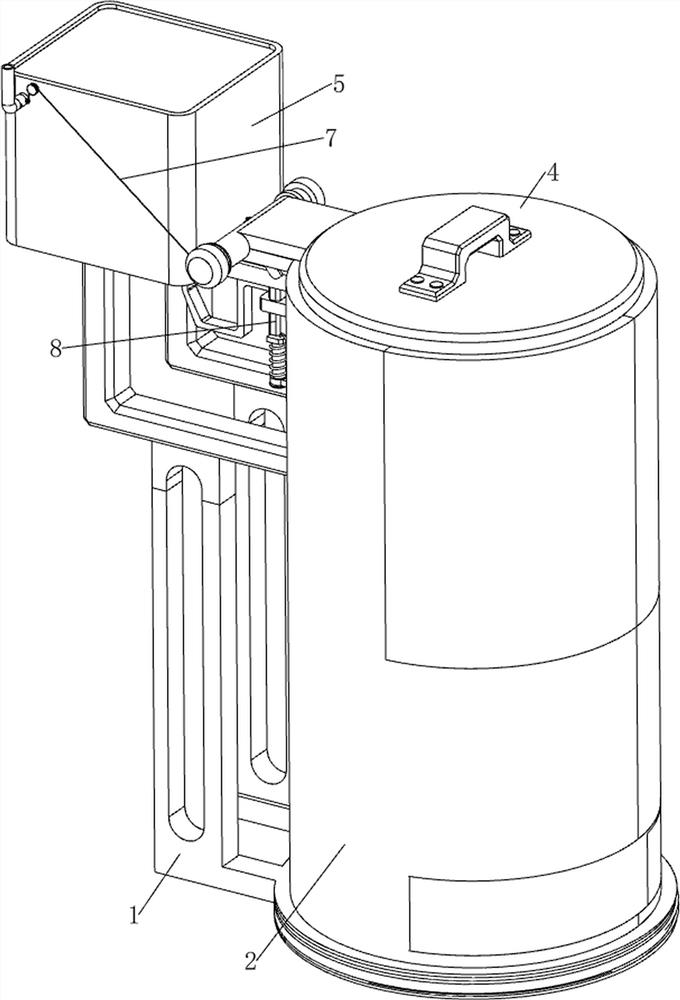

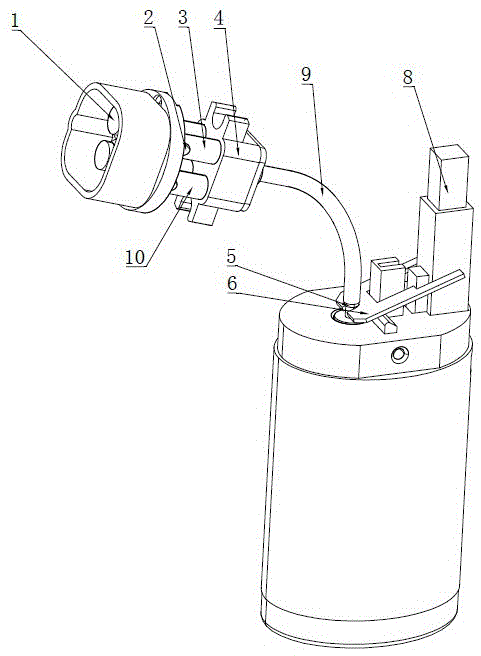

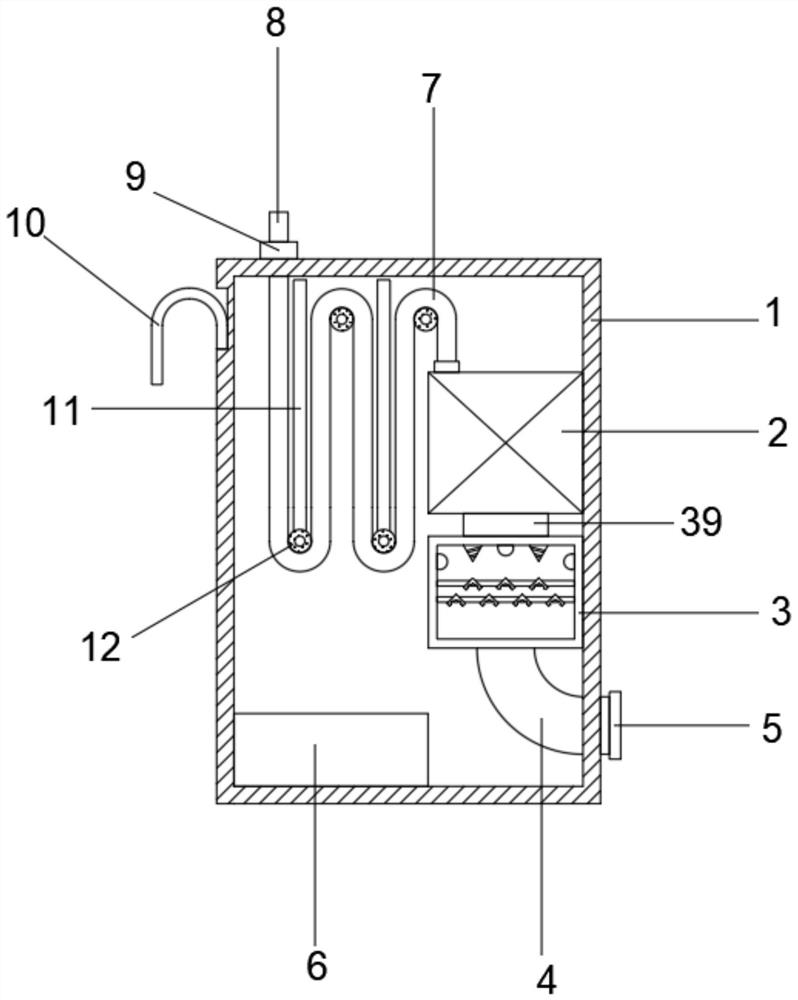

Patient vomitus collecting device for department of gastroenterology

PendingCN114376922AIncrease water jet strengthGood washing effectHollow article cleaningSpittle receiving devicesBiomedical engineeringWater tanks

The invention relates to a collecting device, in particular to a patient vomit collecting device for the gastroenterology department. The technical problem to be solved by the invention is to provide the patient vomitus collecting device for the gastroenterology department, which can isolate and collect vomitus. A patient vomitus collecting device for the department of gastroenterology comprises a support, a cylinder, a hopper, a covering assembly and a cleaning assembly, the cylinder is connected to the support, the hopper is arranged on the cylinder, the covering assembly is arranged on the cylinder, and the cleaning assembly is arranged on the support. The first opening and closing assembly is arranged, when a patient vomits, the first ball valve blocks the sewer pipe, then water is stored in the water tank, after the patient vomits, the first ball valve blocks the sewer pipe again, and then water does not flow into the water tank any more.

Owner:黄志新

A multi-flame lighter

ActiveCN103486609BImprove atomization effectIncrease the spray forceFuel lightersEngineeringGas supply

The invention relates to a multi-flame lighter, which mainly solves the problems of complex structure, weak flame strength and high manufacturing cost existing in the conventional lighter in use. At least two groups of flame components (10) are arranged; a splitter (4) is hermetically connected between the flame components (10) and a gas outlet valve (5); a gas atomization chamber (43) is arranged in the splitter (4); the upper end of the splitter (4) is provided with a gas outlet (41) which is connected with a gas supply pipeline (3), and the lower end of the splitter (4) is provided with a gas inlet (42) which is connected with the gas outlet valve (5). The multi-flame lighter has the characteristics of simple structure, uniform lighting and stable flame strength.

Owner:WENZHOU JONBON SMOKING SETS MANUFACTRUING CO LTD

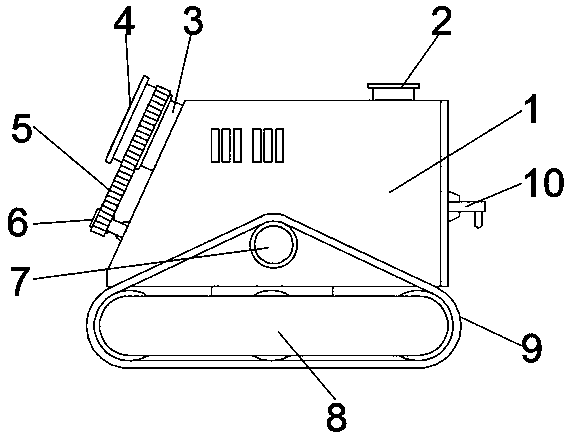

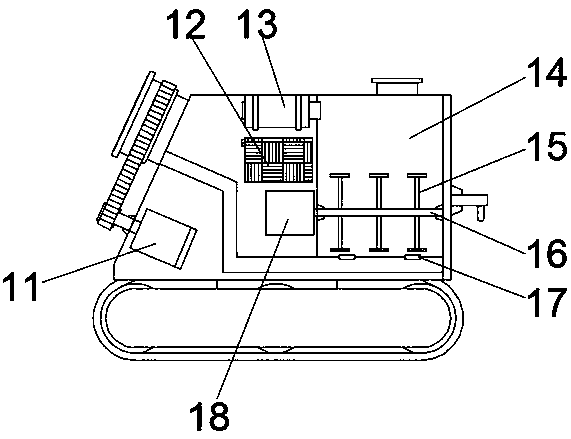

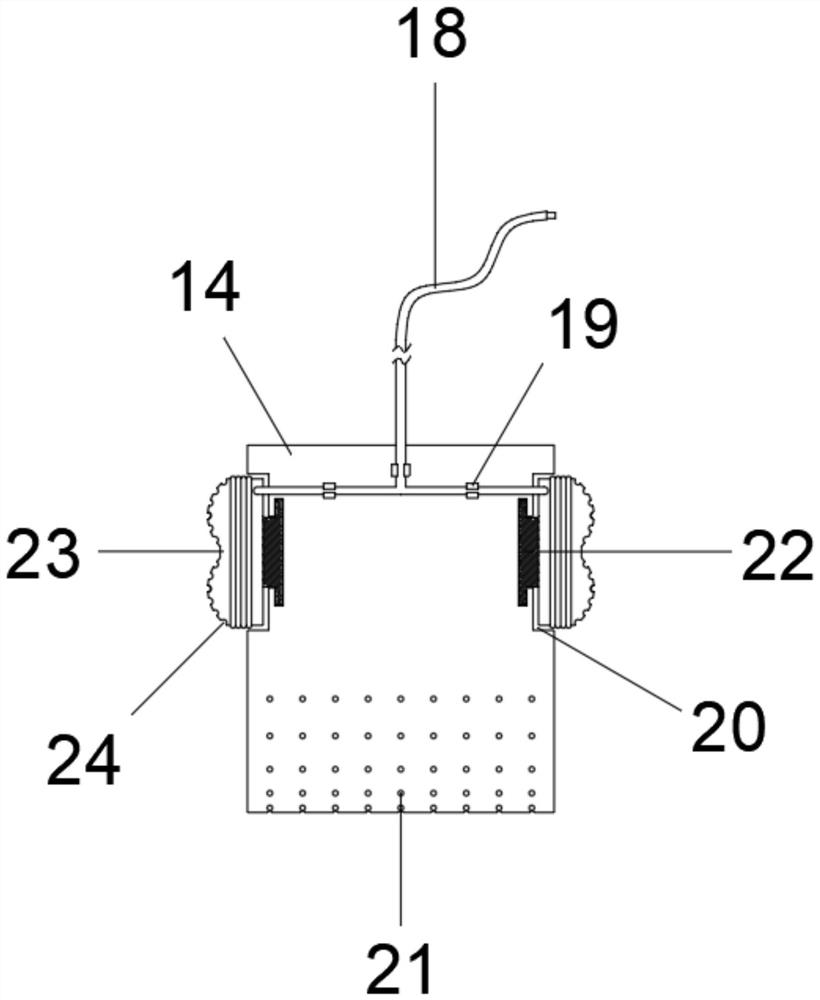

Pneumatic sprayer for fruit tree planting

PendingCN109511634APrevent precipitationThe liquid contains a uniform amount of medicineTransportation and packagingRotary stirring mixersFruit treeEngineering

The invention relates to the technical field of fruit tree irrigation, in particular to a pneumatic sprayer for fruit tree planting. The pneumatic sprayer comprises a main pneumatic sprayer body, a spraying port and a crawler belt frame; the spraying port is fixedly formed in one side of the main pneumatic sprayer body, an atomizing disk is fixedly installed at the other end of the spraying port,a liquid storage chamber is fixedly installed in the main pneumatic sprayer body, a rotating shaft is fixedly installed in the liquid storage chamber, and stirring rods are fixedly installed on the rotating shaft; the bottom of the liquid storage chamber is provided with a liquid outlet, an air compressor is fixedly installed at one side of the liquid storage chamber, a storage battery is fixedlyinstalled below the air compressor, and a stirring motor is fixedly installed below the storage battery. According to the pneumatic sprayer, through the arrangement of the rotating shaft and the stirring rods, the rotating shaft is driven by the stirring motor to rotate, the stirring rods fixedly installed on the rotating shaft stir the bottom of the liquid storage chamber, pesticide is preventedfrom precipitation, and when the pneumatic sprayer is in use, the pesticide liquid content of sprayed liquid is more uniform.

Owner:徐州伟创生态农业科技有限公司

Quenching furnace

The invention discloses a quenching furnace, which comprises a hearth, and a blanking channel which is arranged at a discharge end of the hearth and is communicated with a quenching groove; wherein an oil curtain mechanism is arranged between the lower part of the blanking channel and the quenching groove and comprises an oil curtain chamber, the upper end of the oil curtain chamber is communicated with the blanking channel and the lower end of the oil curtain chamber is communicated with the quenching groove; an oil injection pipe which transversely extends and an arc-shaped oil curtain plate which is positioned below the oil injection pipe are respectively arranged on two opposite side walls of the oil curtain chamber; a plurality of nozzles facing towards the arc-shaped oil curtain plate are formed on the oil injection pipe and are axially distributed along the oil injection pipe; and the arc-shaped oil curtain plate is arched downwards and extends towards the blanking channel. Theinvention provides the improved oil curtain mechanism on the basis of related patents, a large amount of steam and a large amount of oil smoke in the quenching groove are effectively prevented from entering the hearth, the problem that an oil duct is frequently blocked is solved, and the maintenance cost of equipment is saved.

Owner:苏州工业园区热处理设备厂有限公司

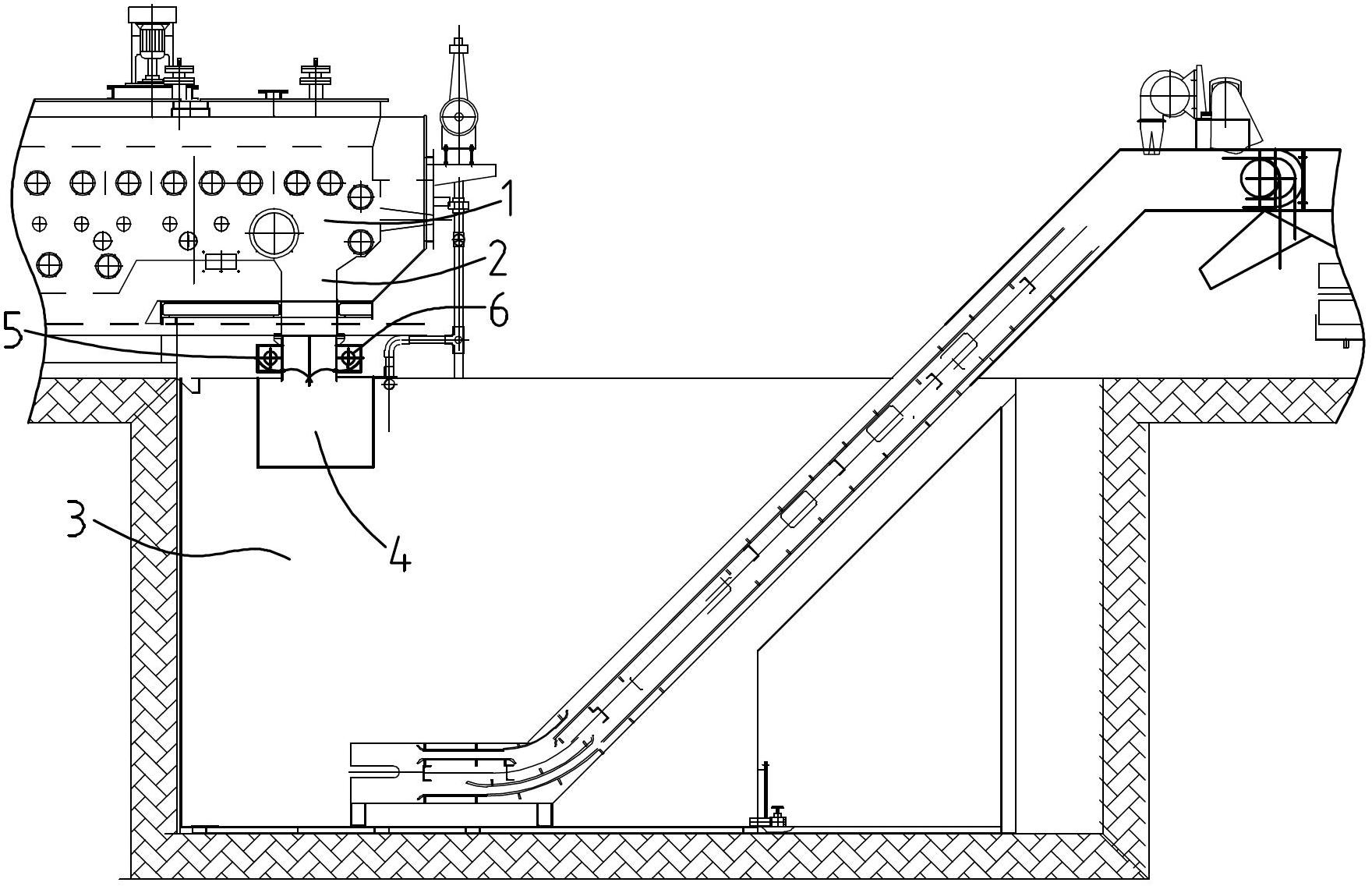

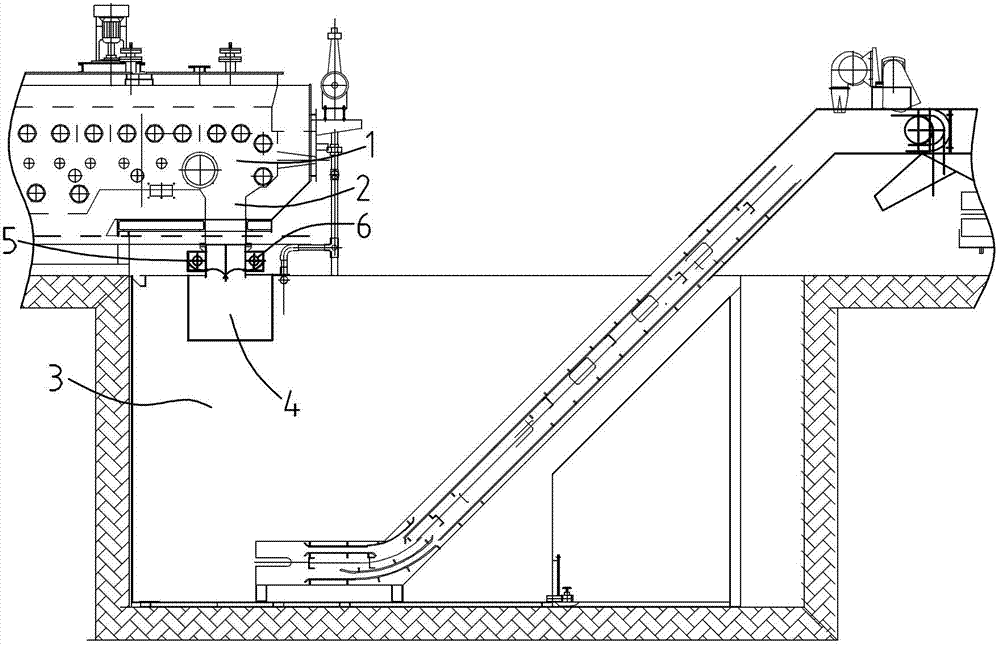

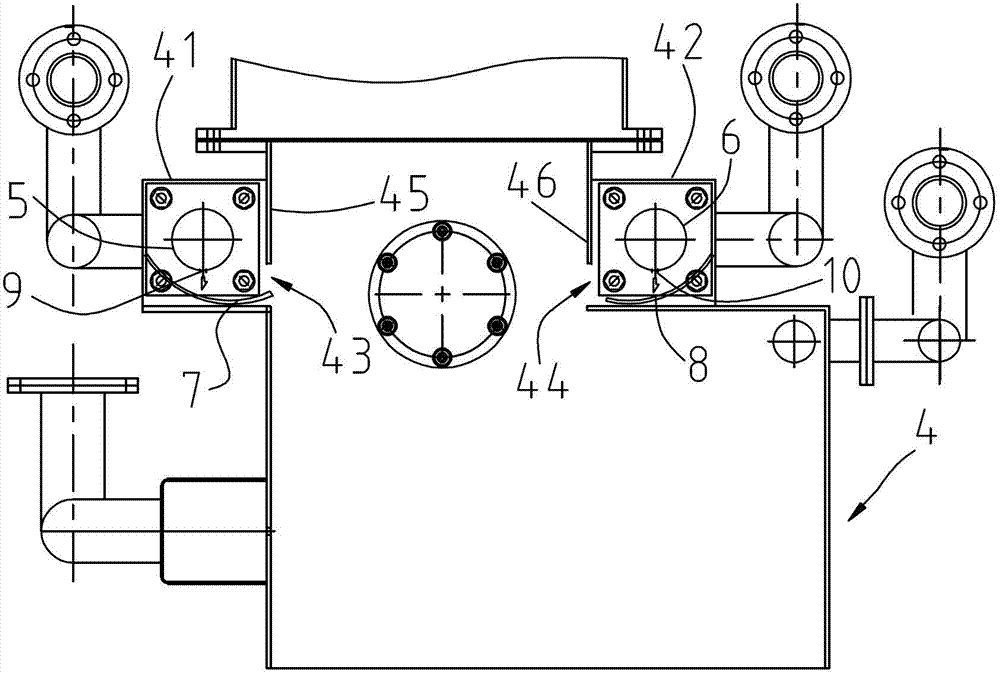

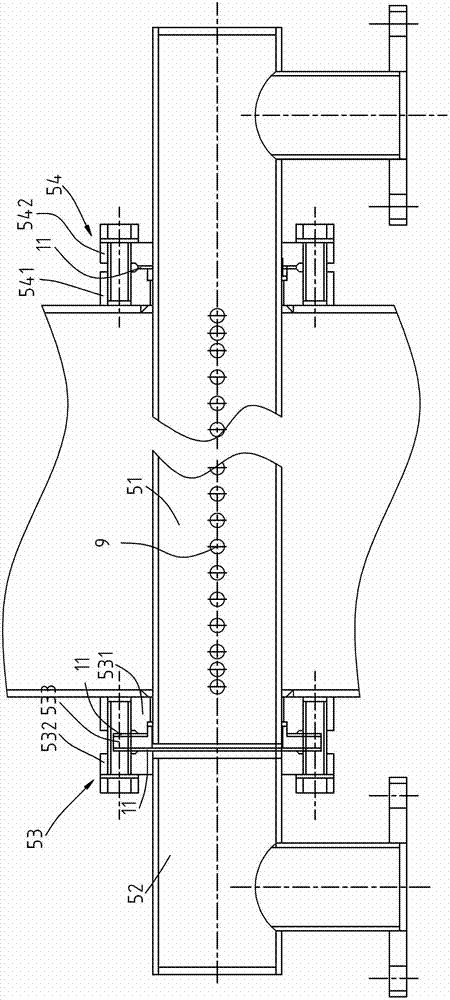

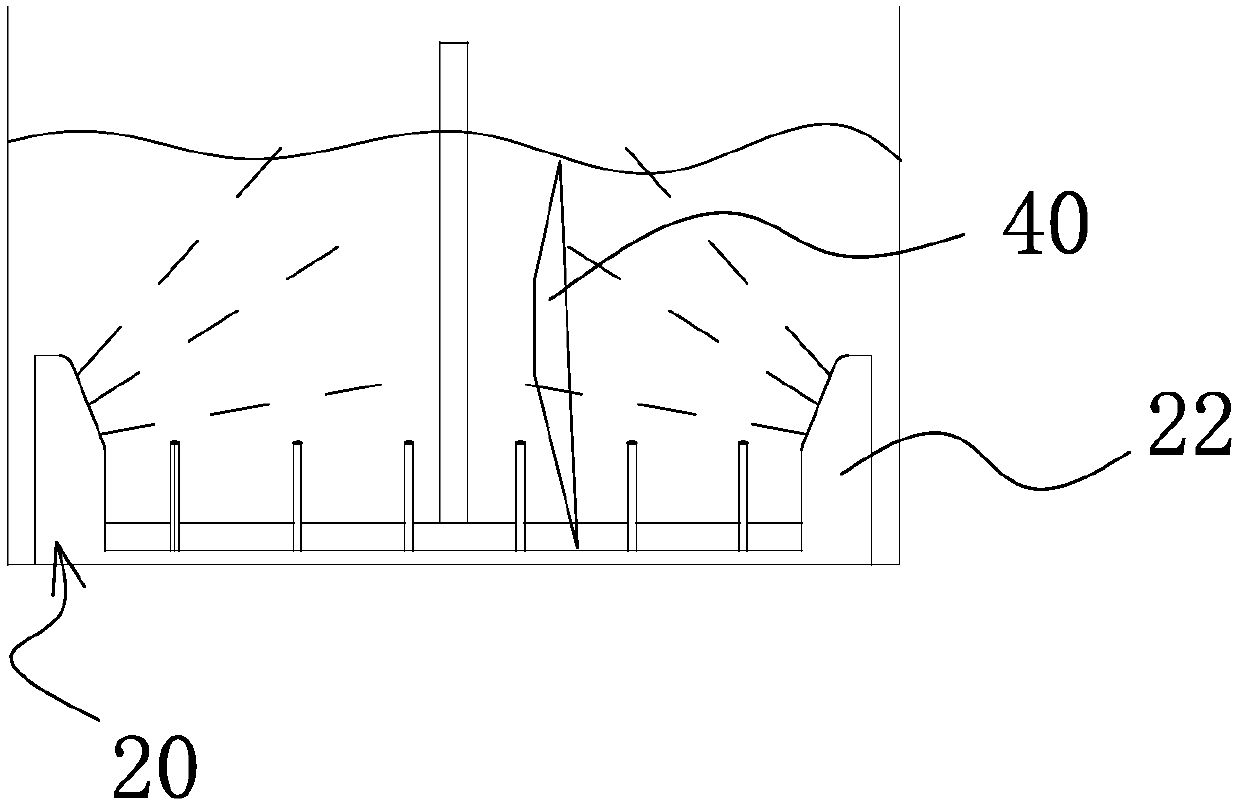

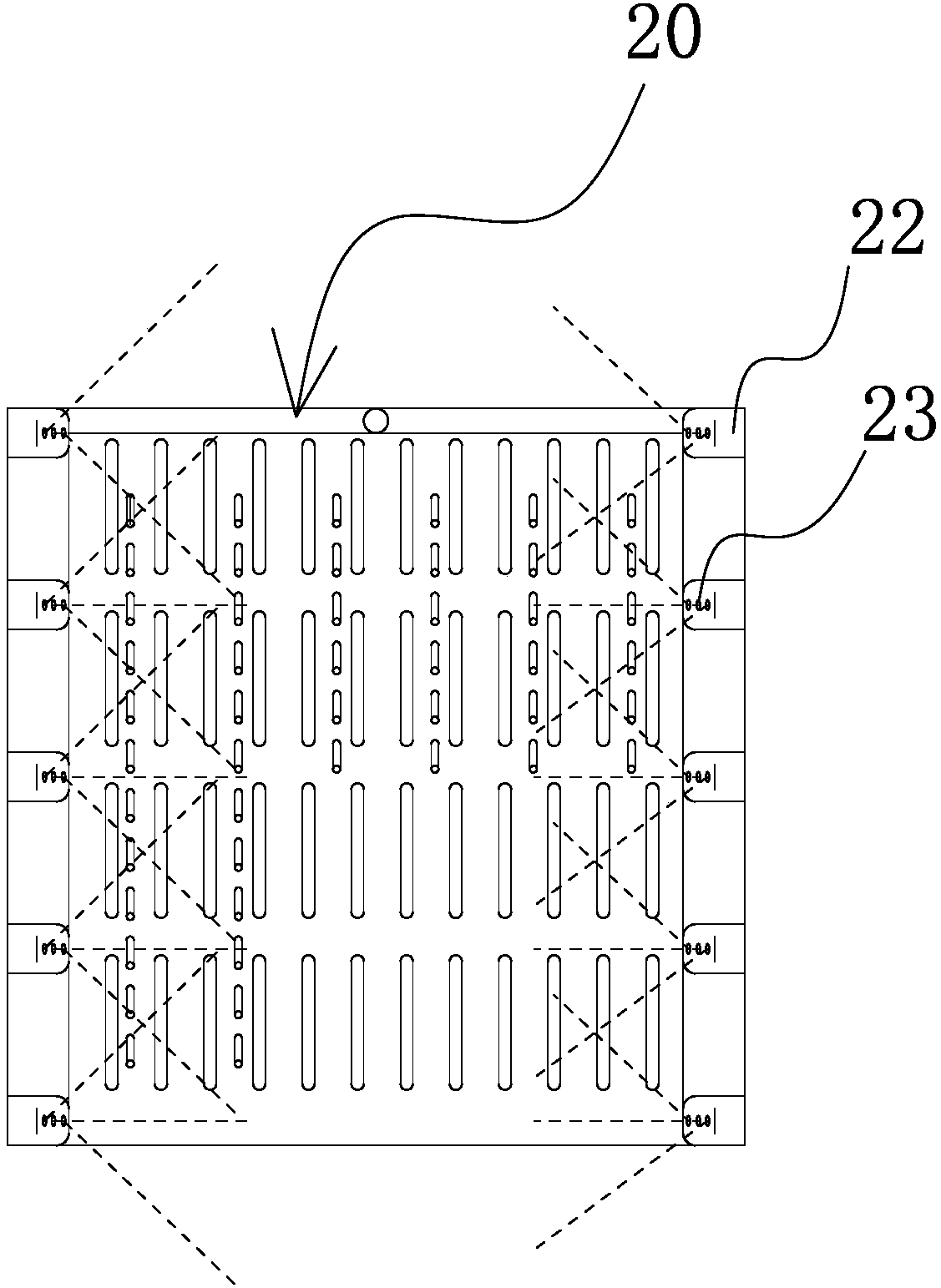

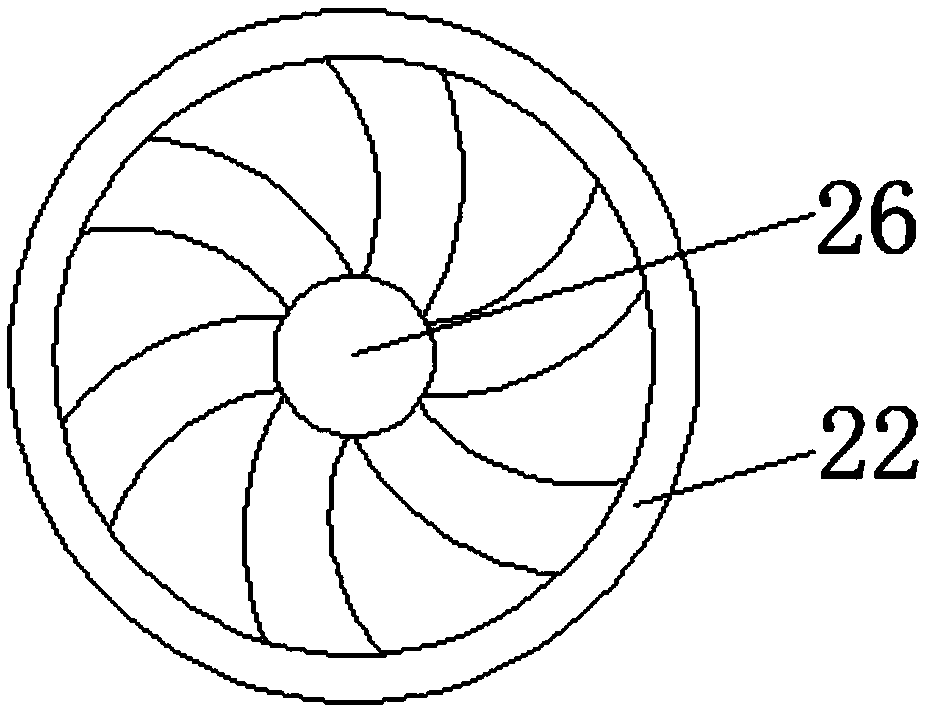

Air-water dual-purpose packing plug-flow device

ActiveCN104003506BIncrease storage spaceIncrease the spray forceSustainable biological treatmentBiological water/sewage treatmentSuction forceFilling materials

The invention discloses a gas-water dual-use filling material circular plug flow device, which comprises a material conveying tube for conveying a filling material, a power plant for providing a medium, a guiding and conveying member for conveying the medium, and an injection member which is used for guiding the medium in the guiding and conveying member to move in the material conveying tube to generate a pushing force or a suction force, and the guiding and conveying member is communicated with the injection member. The gas-water dual-use filling material circular plug flow device is arranged in an aeration tank and below the water surface, a feed end of the material conveying tube is arranged near a filling material stacking position, and a discharge end of the material conveying tube is arranged at a position in alignment to a principle stacking position; a support frame is arranged in the aeration tank to fix the device, the injection member guides vortex motion of the medium, so that a powerful pushing force or suction force is formed in the material conveying tube to together suck the filling material in the stacking position and sewage in the aeration tank in, the filling material is pushed backwards out by the pushing force formed in the material conveying tube, and the problem of filler stacking can be quickly solved.

Owner:ZHEJIANG LIANCHI WATER EQUIP

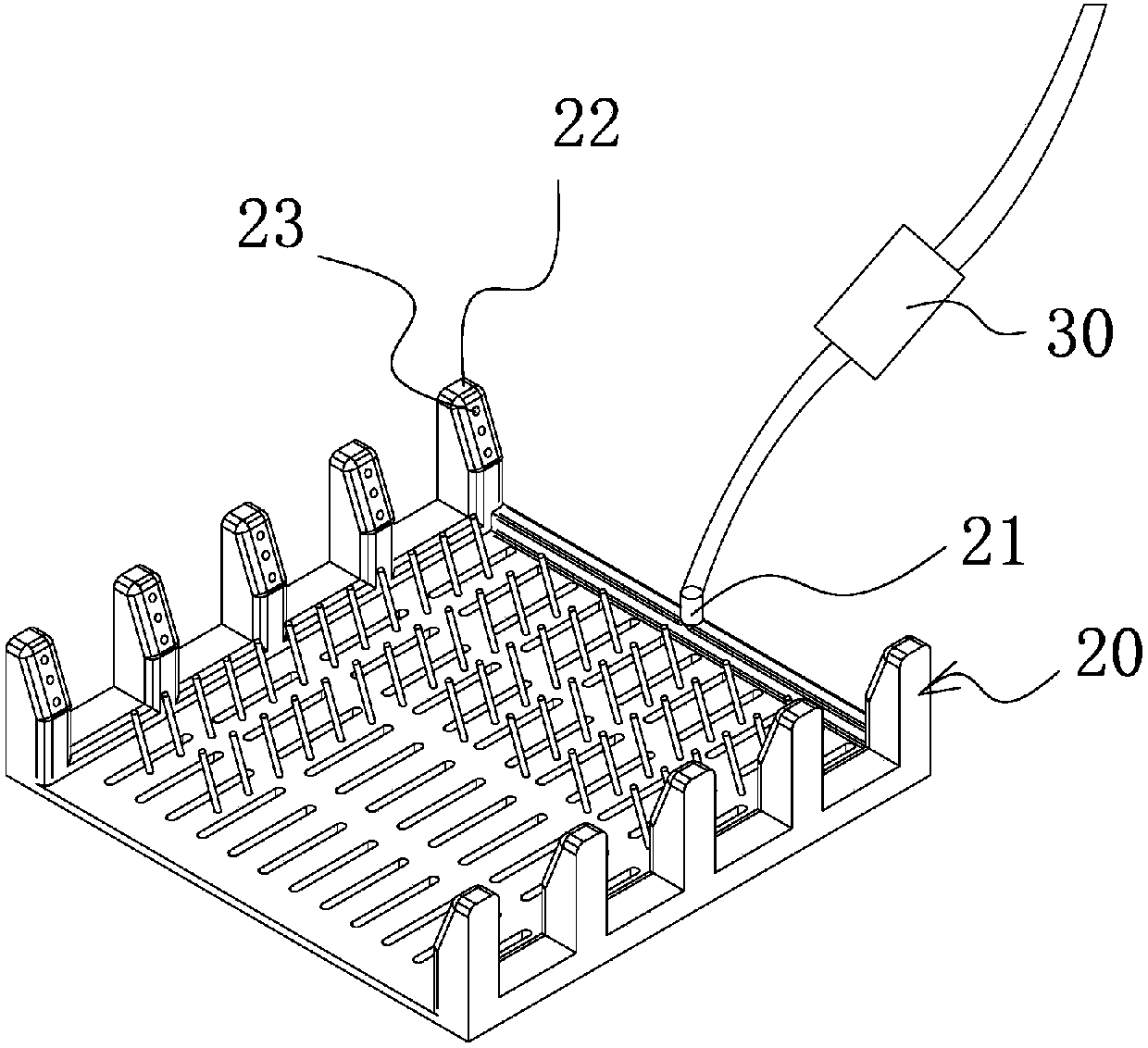

Portable cleaning machine

PendingCN107928580AIngenious structural designPromote sheddingTableware washing/rinsing machine detailsCutleryProcess engineering

The invention discloses a portable cleaning machine, which includes a water inlet tube, a spraying rack and a water inlet hole connecting with the water inlet tube. Convenient cutlery and a place to put fruits are provided on the spraying rack. At least one hollow bulge is provided on each side of the spraying rack. A spraying hole is provided on the bulge. The fluid passing through the water inlet tube passes through the water inlet hole, spraying out through the spraying hole on the bulge. The portable cleaning machine has the advantages of ingenious design and good cleaning effects.

Owner:NINGBO OULIN KITCHEN UTENSILS

Improved desulfurization and denitrification spray gun

InactiveCN104001418BReduce manufacturing costExtended service lifeDispersed particle separationSpray nozzleDenitrification

The invention discloses an improved type desulfurization and denitrification spray gun which comprises a first tube, a second tube, a third tube and a fourth tube which are arranged in sequence from inside to outside and are connected at intervals through support rings, wherein one end of the first tube is blocked by an end plug for sealing; a through hole is formed in the other end of the first tube; the part between each of two ends of the second tube and the outer wall of the first tube is sealed by using an end seal; the part between each of two ends of the third tube and the outer wall of the second tube is sealed by using an end seal; the part between one end of the fourth tube and the outer wall of the third tube is sealed by using another end seal; the other end of the fourth tube is sealed by using another end seal; a plurality of nozzle components which are arranged at intervals in the radial direction and the axial direction are arranged on the wall of the fourth tube; a plurality of second connectors which face outwards are formed on the wall of the second tube; the second connectors penetrate through the wall of the third tube; urea tubes are arranged among the second connectors and the nozzle components; a plurality of convex third connectors are formed on the wall of the third tube; air tubes are arranged among the third connectors and the nozzle components. By adopting the spray gun, the desulfurization and denitrification working efficiency is improved, meanwhile the service life is prolonged, and the use cost is lowered for companies.

Owner:姜建勇

Low-carbon and environment-friendly landscaping device

InactiveCN108902089AImprove spraying effectIncrease the spray forceInsect catchers and killersLandscapingEngineering

The invention provides a low-carbon and environment-friendly landscaping device and relates to the field of landscaping devices. The low-carbon and environment-friendly landscaping device comprises alandscaping device body; the bottom of the landscaping device body is fixedly connected with universal wheels; an inner cavity of the landscaping device body is fixedly connected with a placing plate;one side of the top of the placing plate is fixedly connected with a pesticide box and a booster pump; the booster pump is located at the right side of the pesticide box; the left side of the boosterpump is fixedly connected with an input pipe; one side of the input pipe passes through the top of the placing plate and extends to the downside of the placing plate. According to the low-carbon andenvironment-friendly landscaping device, a pesticide liquid is pumped out of the pesticide box due to the matching of the booster pump and an output pipe, is sequentially sprayed through the input pipe, a hose and a water outlet and is sprayed on diffusion blades, and the low-carbon and environment-friendly landscaping device rotates due to the matching of a rotating disk, a rotating support and arotating bearing, so that the pesticide liquid is uniformly diffused all around through uniform diffusion of the diffusion blades.

Owner:XIAOGAN QISIMIAOXIANG CULTURAL MEDIA

Cleaning device for electric blanket

InactiveCN108049047AIncrease the spray forceQuick washLiquid/gas/vapor removal by suctionTextile treatment machine arrangementsMultiple injectionEngineering

The invention discloses a cleaning device for an electric blanket. The device comprises an aerating box which is internally provided with a piston rod capable of moving in a reciprocating mode, a first air delivery pipe is arranged on the upper portion of the aerating box, a second air delivery pipe is arranged on the lower portion of the aerating box, a third valve is arranged in the second air delivery pipe, a first branched pipe and a second branched pipe which are communicated with the first air delivery pipe are arranged on the first air delivery pipe, the first branched pipe is internally provided with a first valve, the second branched pipe is internally provided with a second valve, a rectangular frame pressure pipe is arranged one side of the aerating box, a U-type pipe communicated with the pressure pipe is arranged on the pressure pipe, the pressure pipe is communicated with the second air delivery pipe, multiple injection pipes facing the U-type pipe are arranged on the pressure pipe, the injection pipes are uniformly distributed at the upper end and the lower end of the pressure pipe, the injection pipes located at the upper end of the pressure pipe are communicated with the first branched pipe, and the injection pipes located at the lower end of the pressure pipe are communicated with the second branched pipe. Both cleaning and rapid drying can be achieved.

Owner:宁波隆锐机械制造有限公司

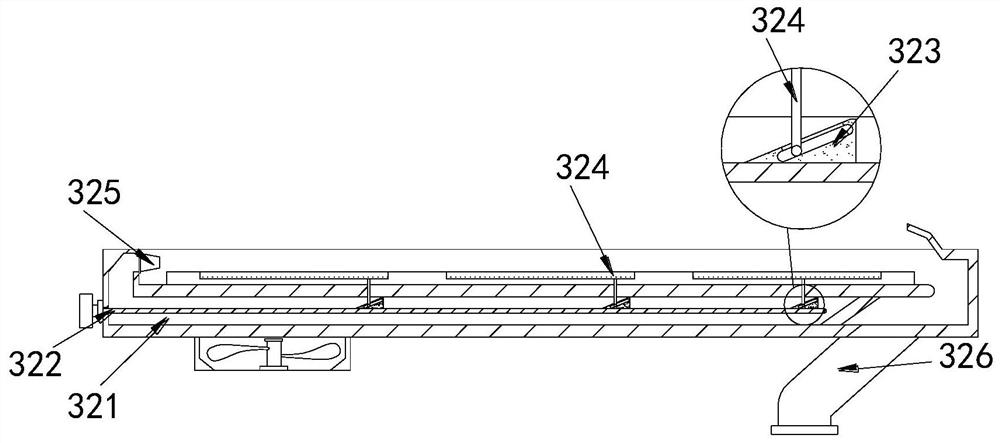

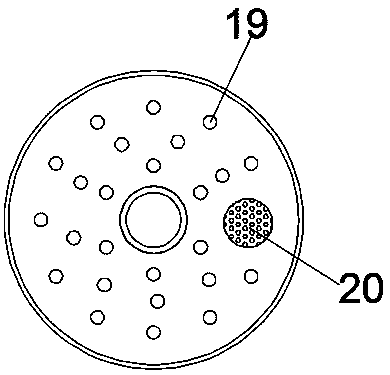

A Jet Flow Plate Used in a Noodle Cooking Stove

ActiveCN108041977BImprove the heating effectImprove tumbling effectWater-bath cooking vesselsThermodynamicsWater flow

The invention relates to a jet plate used for a noodle cooking furnace, and belongs to the field of food processing equipment. A main body of the jet plate is provided with a main water jet hole and an auxiliary water jet hole; a noodle cooking furnace body includes a deposition bin and a heating pipe, the deposition bin is used for collecting food residues, and the heating pipe is used for heating water and arranged at the upper end of the deposition bin. The main body of the jet plate is arranged at the upper end of the heating pipe, and the main body of the jet plate is used for jetting water heated by the heating pipe from bottom to top for noodle cooking. The main water jet hole is used for jetting hot water boiled on the lower portion of the main body of the jet plate to the upper portion of the jet plate so as to impact noodles, the rolling effect is generated, when water flow from the main water jet hole impacts the noodles, water flow jetted from the auxiliary water jet hole impacts the peripheries of the noodles, and the heating speed and the heating effect are further improved.

Owner:ANHUI HUALING KITCHEN EQUIP

Medicine applying device special for gynecology department

The medicine applying device comprises an air supply box and a syringe, a storage battery is fixed to the inner wall of the bottom of the air supply box through screws, a mounting groove is formed in the outer wall of one side of the air supply box, a hook is fixed to the inner wall of the mounting groove through screws, and an air pump is fixed to the inner wall of one side of the air supply box through screws; a connecting pipe is fixed to the outer wall of the bottom of the air pump through screws, a heating box is fixed to one end of the connecting pipe through screws, the heating box is fixed to the inner wall of one side of the air supply box through screws, and an air inlet pipe is fixed to the outer wall of the bottom of the heating box through screws. According to the device, the intubation tube, the gas receiving tube, the injection tube, the piston, the gas filling tube and the gas bag are arranged, the injection tube and the sleeve head are placed into the vagina of a patient, gas is introduced into the gas filling tube, at the moment, the inner wall of the vagina of the patient is supported through the gas bag, pain is relieved, and treatment on the patient is facilitated.

Owner:广州美德电子商务有限公司

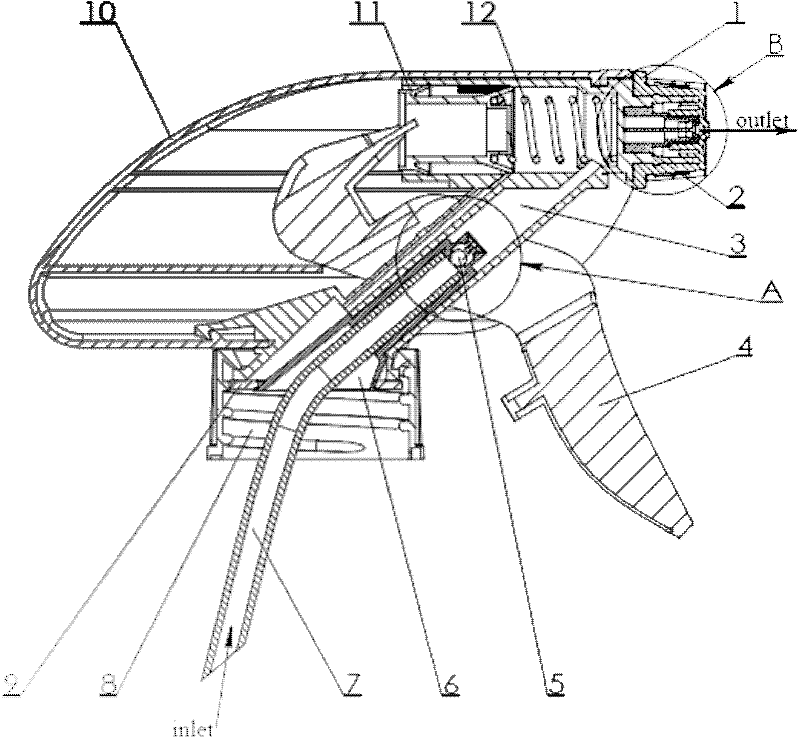

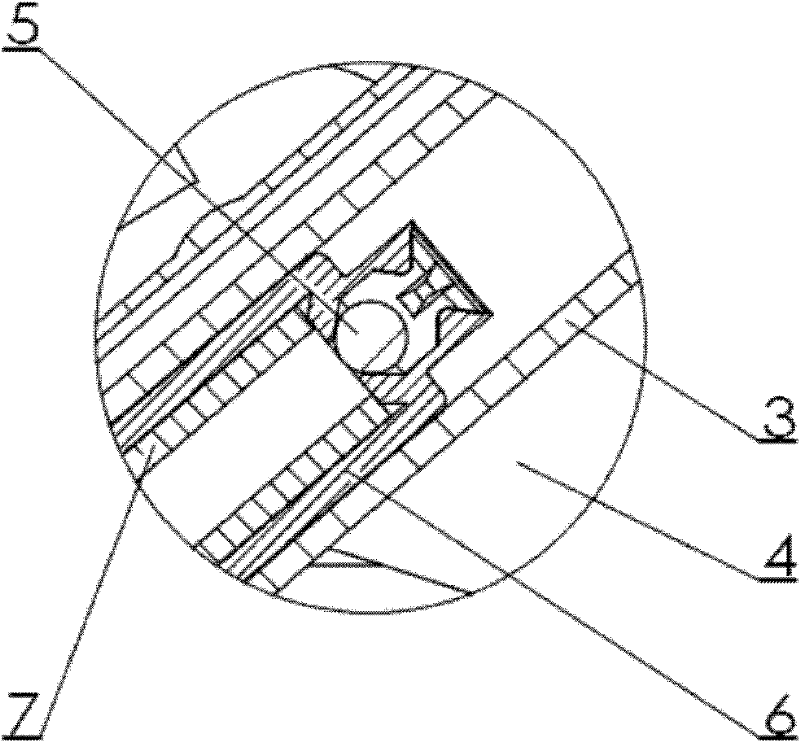

Novel hand micro-sprayer

The invention relates to a novel hand micro-sprayer, which comprises a main body. A nozzle chock plug and a nozzle cage are installed at the front end of the main body. A spanner is installed on the main body. An outer cover is installed outside the main body. The cavity of the main body is an oblique T-shaped structure, the bottom part of the main body is a horn-shaped hood and the middle of themain body is a drainage tube. The drainage tube is upward and obliquely connected with a horizontally arranged piston cylinder. The piston cylinder is communicated with the drainage tube through a water inlet opening. A water outlet opening is arranged at the front end of the piston cylinder. A piston is installed in the piston cylinder. A cylindrical compression spring is installed between the piston and the water outlet opening. The spanner is installed on a spanner rotating shaft at the middle part of the drainage tube through a knuckle hole on the spanner. The upper front end of the spanner is close to the external end of the piston. A ball valve seat is installed in the drainage tube and comprises a ball valve cavity installed with a ball valve, a hollow cylindrical tube and a horn-shaped opening. A suction tube is installed in the hollow cylindrical tube. The invention has the advantages of compact structure, large injection volume and effort saving during spanner turning.

Owner:ZHEJIANG UNIV OF TECH +1

Intelligent medical atomizer for children

InactiveCN112675388AGuaranteed atomization effectIncrease the spray forceMedical atomisersOral problemsDentistry

The invention provides an intelligent medical atomizer for children. The intelligent medical atomizer comprises an L-shaped plate, a centrifugal motor, a handheld grip, a limiting and fixing unit, an atomizing unit and a water injection unit. The intelligent medical atomizer solves the main problems that when a child uses an atomizer currently, the oral cavity of the child is small and cannot be stably fixed, tooth ache is caused in the process of fixing in the oral cavity of the child, tooth development of the child is affected, the child feels uncomfortable and is prone to moving in the using process and then the atomization effect is affected; and the intelligent medical atomizer further solves the problems of non-uniform atomized particles, relatively small atomization spraying force, non-ideal atomizing effect and the like of the existing atomizer in the medicament atomizing process.

Owner:吕宝用

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com