Novel hand micro-sprayer

A sprayer and hand button technology, which is applied in the field of new hand button type micro sprayers, can solve the problems of less liquid ejection, laborious wrench pulling, and large liquid ejection, so as to improve the ejection amount and the ejection strength, and save the handshake. , Increase the effect of the handle area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

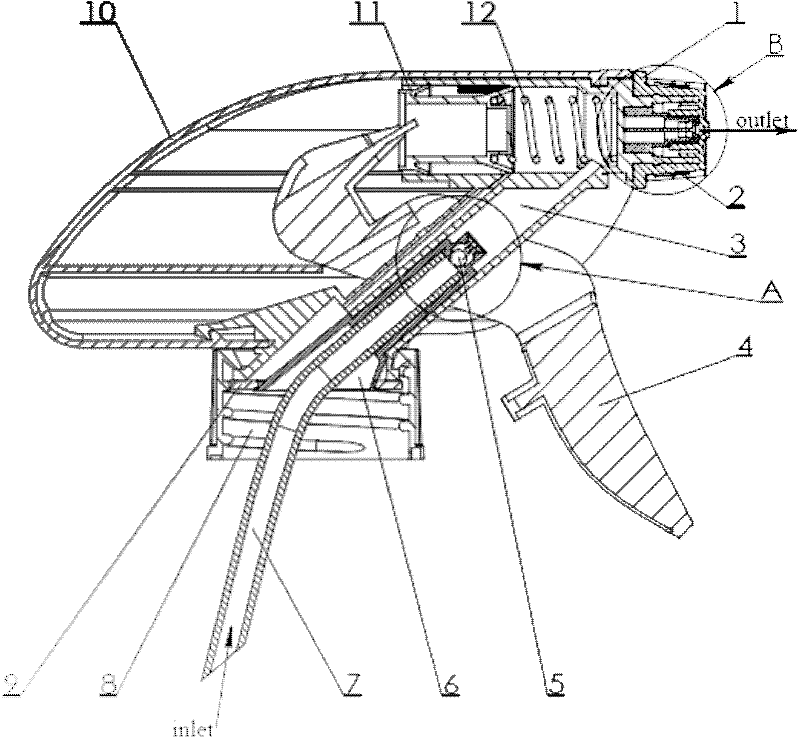

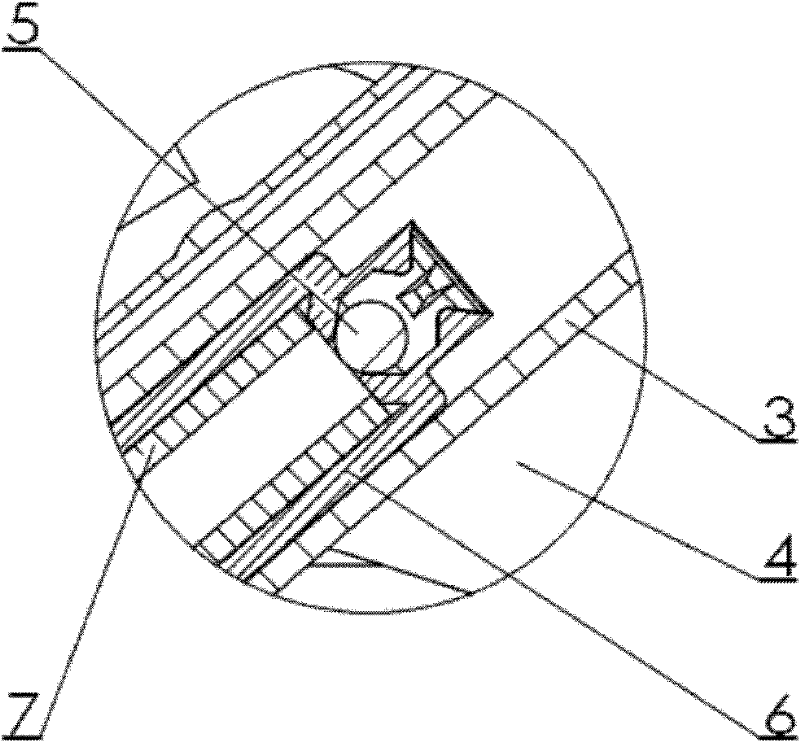

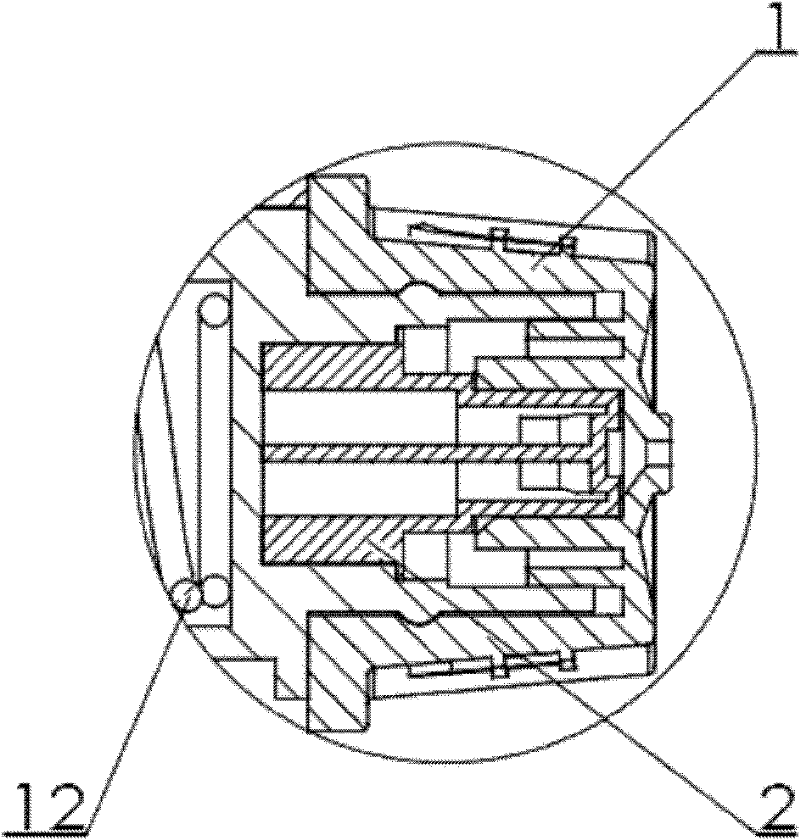

[0032] refer to Figure 1-17 , a novel hand button micro-sprayer, including a main body 3, a nozzle plug 2 and a nozzle cover 1 are installed on the front end of the main body 3, a wrench 4 is installed on the main body 3, and an outer cover 10 is installed outside the main body 3, The bottom of the main body 3 is connected with the bottle cap 8, the cavity of the main body 3 is an oblique T-shaped structure, the bottom is a trumpet-shaped cover 3-1, and the middle is a drainage tube 3-2, and the drainage tube 3-2 is connected with a horizontally arranged piston cylinder 3-4 obliquely upward, and the piston cylinder 3-4 communicates with the drainage pipe 3-2 through the water inlet 3-3, and the front end of the piston cylinder 3-4 is provided with A water outlet hole 3-5; a piston 11 is installed in the piston cylinder 3-4, and a cylindrical compression spring 12 is installed between the piston 11 and the water outlet hole 3-5; a wrench is provided in the middle of the draina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com