Quenching furnace

A technology of quenching furnace and quenching tank, which is applied in the field of quenching furnace, can solve the problems of easy blockage of oil outlet nozzles and complicated disassembly of nozzles, and achieve the effect of improving quenching quality and avoiding carbon formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

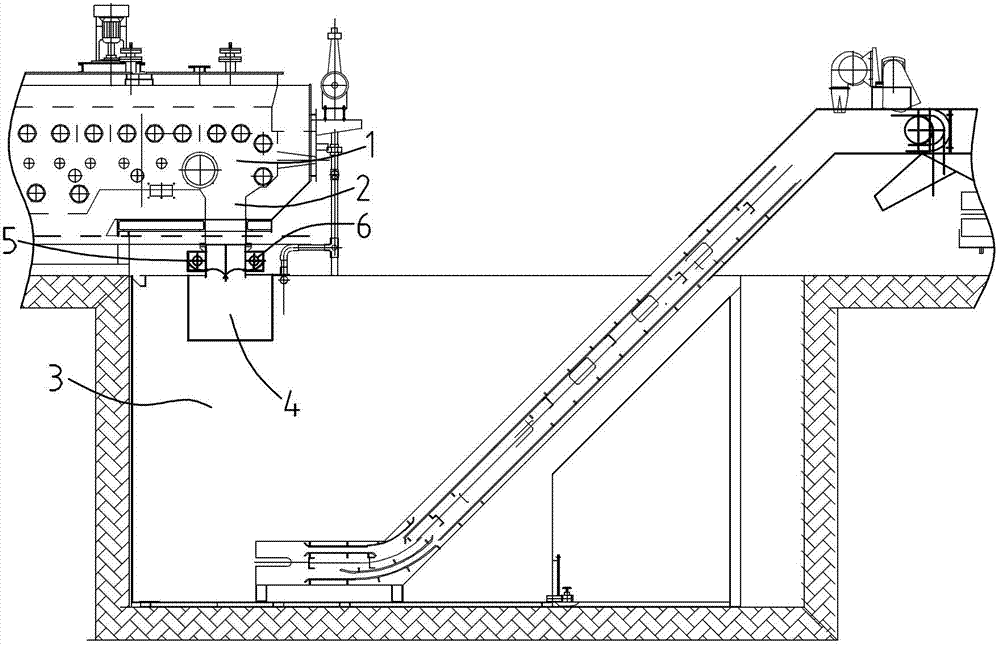

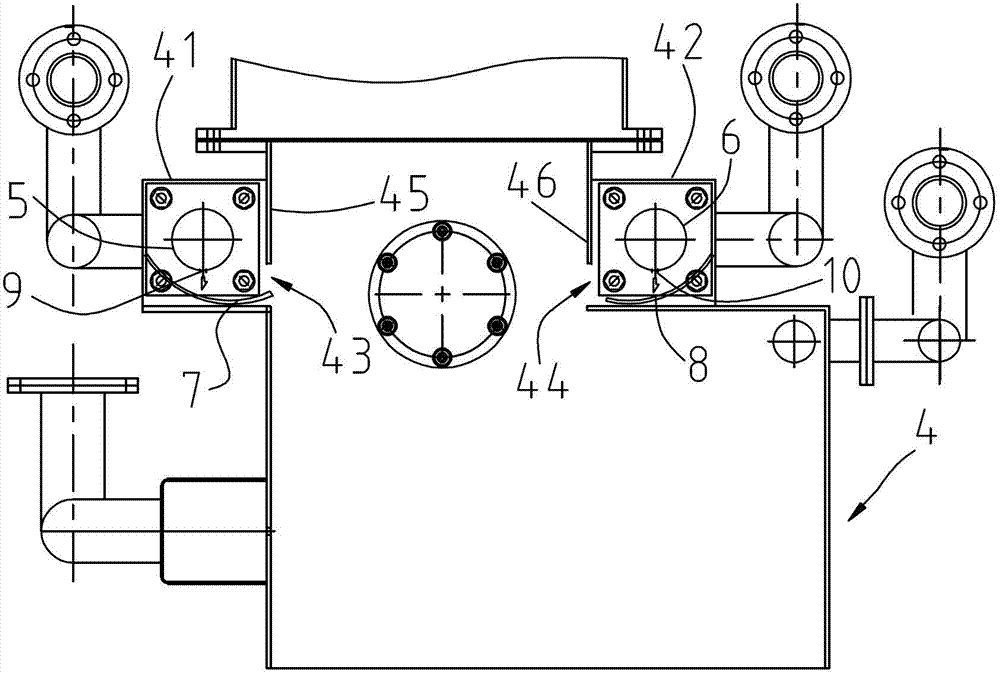

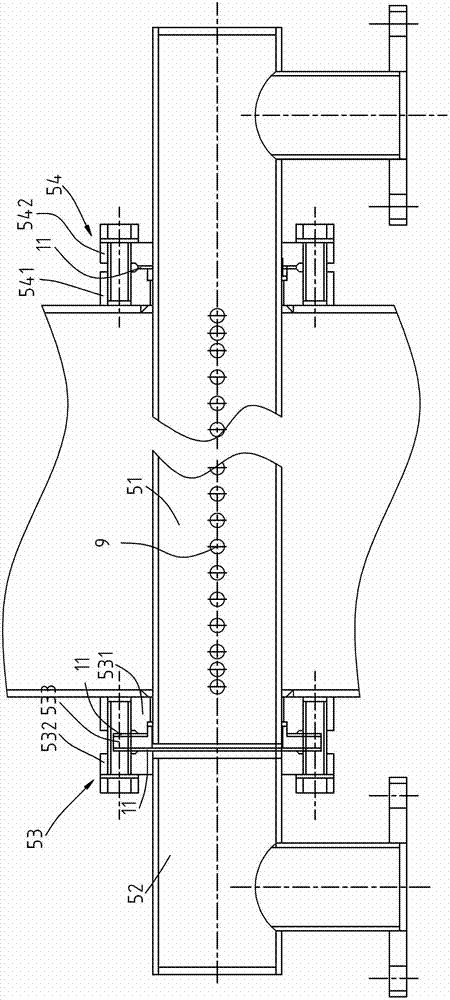

[0025] See attached figure 1 , a quenching furnace of the present invention, comprising a furnace 1, a blanking channel 2 arranged at the discharge end of the furnace 1 and communicated with the quenching tank 3, the lower part of the blanking channel 2 and the quenching tank 3 There is an oil curtain mechanism between them; see attached figure 2 The oil curtain mechanism includes an oil curtain chamber 4 whose upper end communicates with the blanking channel 2 and whose lower end communicates with the quenching tank 3, and the two opposite side walls of the oil curtain chamber 4 are respectively The first oil injection pipe 5 and the second oil injection pipe 6 with the same structure and extending in the transverse direction and the first arc-shaped oil curtain plate 7 located below the first oil injection pipe 5 and the second oil injection pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com