Graphene film cutting equipment

A cutting equipment, graphene technology, applied in stone processing equipment, stone processing tools, cleaning methods and appliances, etc., can solve the problem of carbon powder scratching the end face of graphene film, and achieve the effect of increasing the spraying force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Please refer to Figure 1-Figure 6 , the specific embodiments of the present invention are as follows:

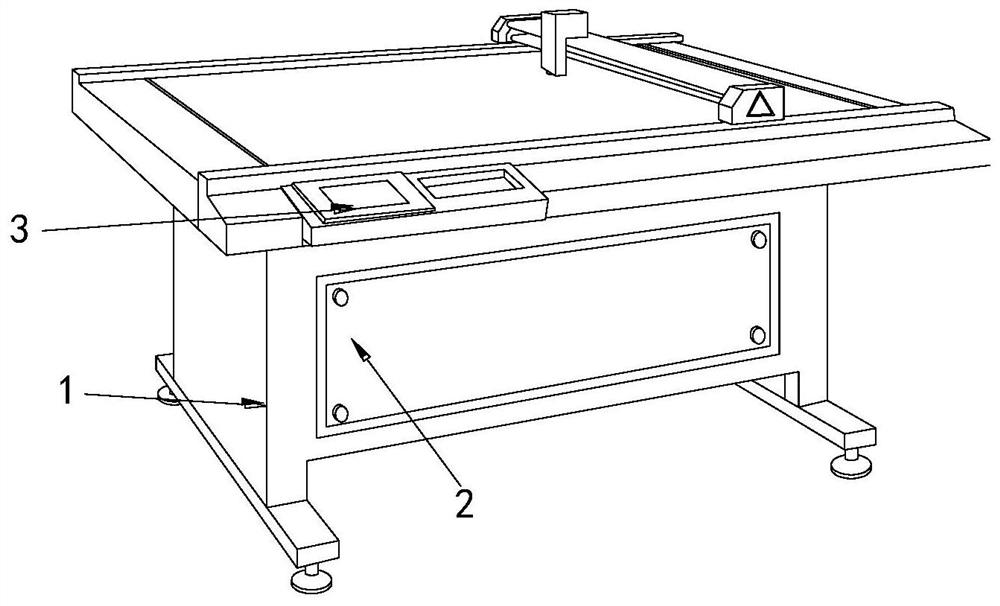

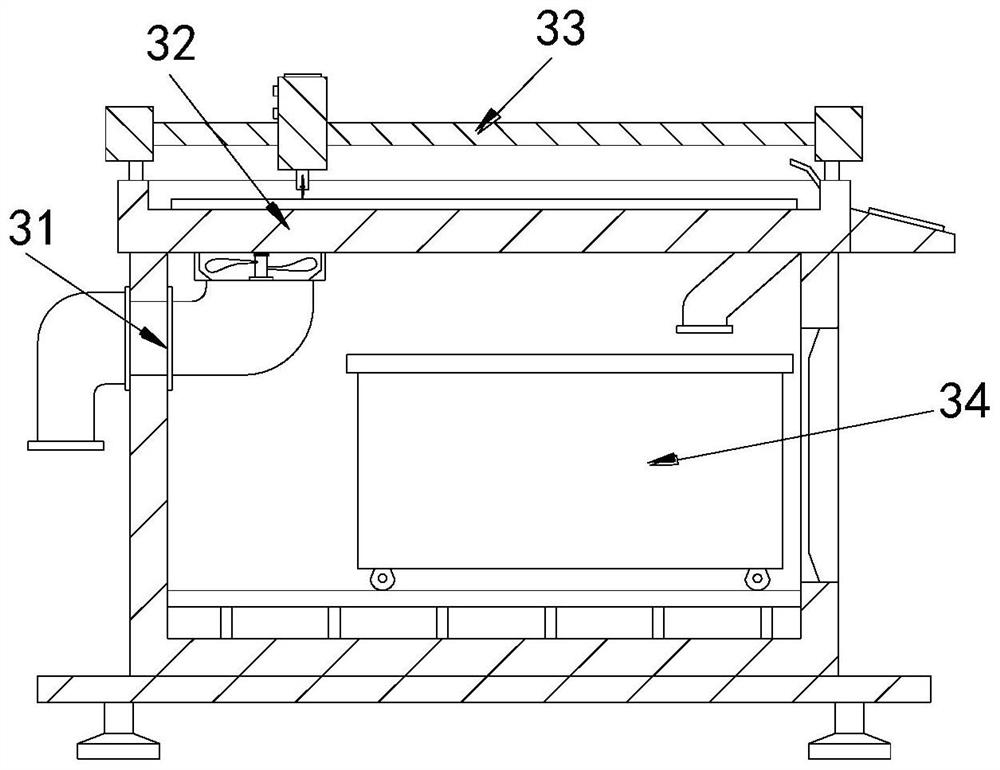

[0029] Its structure includes a main body 1, a box door 2, and a control panel 3. The front end of the main body 1 is provided with a box door 2, and the control panel 3 is installed on the top front end of the main body 1. The main body 1 includes an air intake pipe 31, a cutting table 32. Cutting block 33, dust collection box 34, the air intake pipe 31 is arranged at the side end of the main body 1, the cutting table 32 is installed at the top of the main body 1, and the cutting block 33 is engaged with both ends of the top of the main body 1 , the dust box 34 is arranged at the inner side end of the main body 1 .

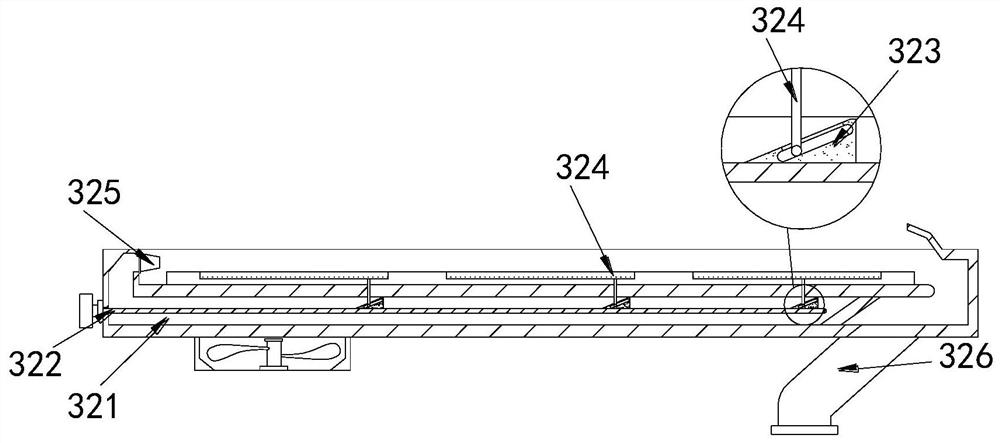

[0030] The cutting table 32 includes a ventilation groove 321, a pull rod 322, a guide block 323, a turning device 324, an air injection device 325, and a feeding pipe 326. The ventilation groove 321 is arranged inside the cutting table 32, ...

Embodiment 2

[0035] Example 2: Please refer to Figure 7-Figure 9 , the specific embodiments of the present invention are as follows:

[0036] The air injection device 325 includes a rubber ball c1, a rear flow hole c2, a splitter c3, and a dispersion sheet c4. Arranged at the rear end of the rubber ball c1, the splitter c3 is provided with three, and vertically arranged at the inner rear end of the air injection device 325, and the dispersion sheet c4 is provided with two, and is located behind two splitters c3 Right in the middle, the angle formed between the dispersing pieces c4 is 30 degrees, which is conducive to stretching the rubber ball c1 through the impact of the air flow, and then using the rubber ball c1 to shrink to eject the internal air to the rear flow hole c2, Increase the jet intensity of the airflow.

[0037] The dispersing piece c4 includes a dispersion body c41, a rotating shaft c42, a rewinding spring c43, a limit block c44, and a guide groove c45. The end surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com