Bullet-proof glass and manufacturing method

A technology of bullet-proof glass and its production method, which is applied in the direction of chemical instruments and methods, glass/slag layered products, protective clothing, etc., which can solve the problems of complex bullet-proof glass processing technology, long time-consuming, and lack of protective performance, so as to improve chemical stability Sexuality and thermal stability, lower viscosity, faster melting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

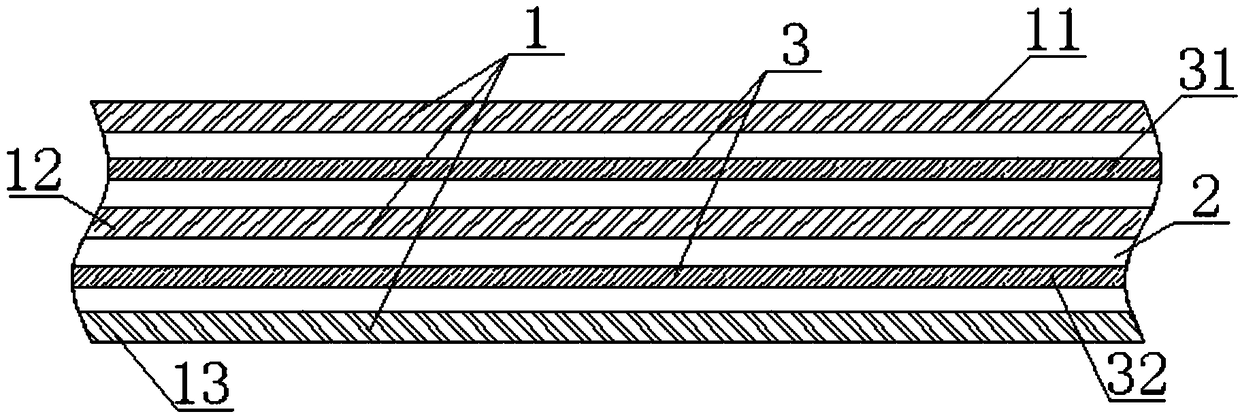

[0039] according to figure 1 A kind of bulletproof glass shown, comprises glass layer 1, hollow layer 2 and glass fiber mesh layer 3, and described glass layer 1 comprises first glass layer 11, second glass layer 12 and third glass layer 13, and described glass layer The fiber mesh layer 3 comprises a first glass fiber mesh layer 31 and a second glass fiber mesh layer 32, the first glass layer 11, the second glass layer 12, the third glass layer 13, the first glass fiber mesh layer 31 and the second glass fiber mesh layer. Two glass fiber mesh layers 32 are arranged alternately, a hollow layer 2 is arranged between the glass layer 1 and the glass fiber mesh layer 3, and the inside of the hollow layer 2 is filled with glue. The batch materials of the glass layer 1 include the following by mass Percent composition: 65.0% SiO 2 , 15.2% CaO, 8.8% BaO, 4.0% Li 2 O, 3.6% K 2 O, 3.2% PbO, 3.0% NaNo 3 and 2.2% H 2 O, where SiO 2 It mainly constitutes the skeleton of the glass to...

Embodiment 2

[0057] according to figure 1 A kind of bulletproof glass shown, comprises glass layer 1, hollow layer 2 and glass fiber mesh layer 3, and described glass layer 1 comprises first glass layer 11, second glass layer 12 and third glass layer 13, and described glass layer The fiber mesh layer 3 comprises a first glass fiber mesh layer 31 and a second glass fiber mesh layer 32, the first glass layer 11, the second glass layer 12, the third glass layer 13, the first glass fiber mesh layer 31 and the second glass fiber mesh layer. Two glass fiber mesh layers 32 are arranged alternately, a hollow layer 2 is arranged between the glass layer 1 and the glass fiber mesh layer 3, and the inside of the hollow layer 2 is filled with glue. The batch materials of the glass layer 1 include the following by mass Percent composition: 70.0% SiO 2 , 14.2% CaO, 7.8% BaO, 3.4% Li 2 O, 3.0% K 2 O, 2.6% of PbO, 2.4% of NaNo3 and 1.6% of H 2 O.

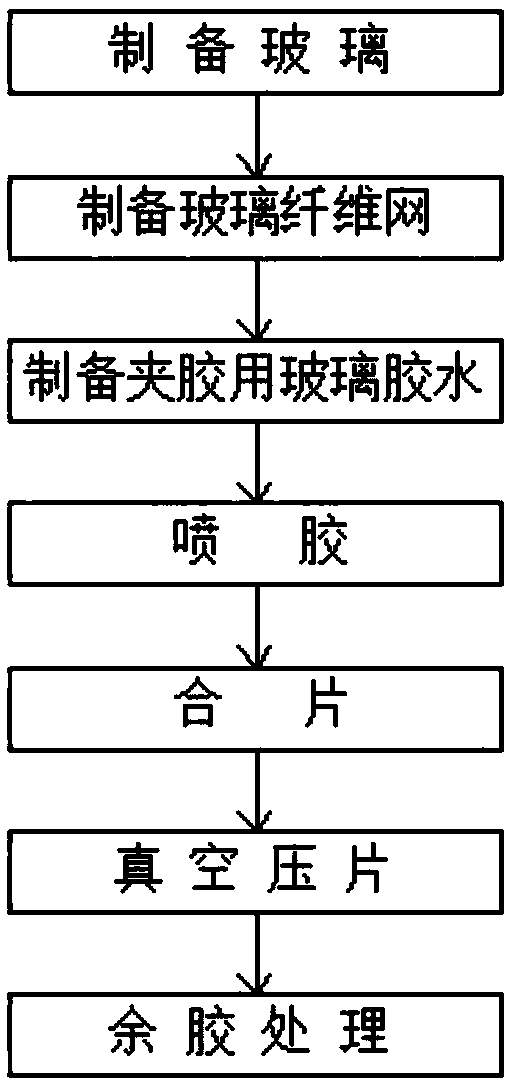

[0058] according to figure 2 A kind of manufacture ...

Embodiment 3

[0075] according to figure 1 A kind of bulletproof glass shown, comprises glass layer 1, hollow layer 2 and glass fiber mesh layer 3, and described glass layer 1 comprises first glass layer 11, second glass layer 12 and third glass layer 13, and described glass layer The fiber mesh layer 3 comprises a first glass fiber mesh layer 31 and a second glass fiber mesh layer 32, the first glass layer 11, the second glass layer 12, the third glass layer 13, the first glass fiber mesh layer 31 and the second glass fiber mesh layer. Two glass fiber mesh layers 32 are arranged alternately, a hollow layer 2 is arranged between the glass layer 1 and the glass fiber mesh layer 3, and the inside of the hollow layer 2 is filled with glue. The batch materials of the glass layer 1 include the following by mass Percent composition: 75.0% SiO 2 , 13.2% CaO, 6.8% BaO, 2.8% Li 2 O, 2.4% K 2 O, 2.0% PbO, 1.8% NaNo 3 and 1.0% H 2 O.

[0076] according to figure 2 A kind of manufacture method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com