3D super-swirling siphon closestool

A toilet and toilet technology, applied in flushing toilets, water supply devices, buildings, etc., can solve the problems of poor sewage discharge effect and water saving effect, and needs to be further improved, so as to improve the water saving effect, reduce residual waste water, and reduce losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

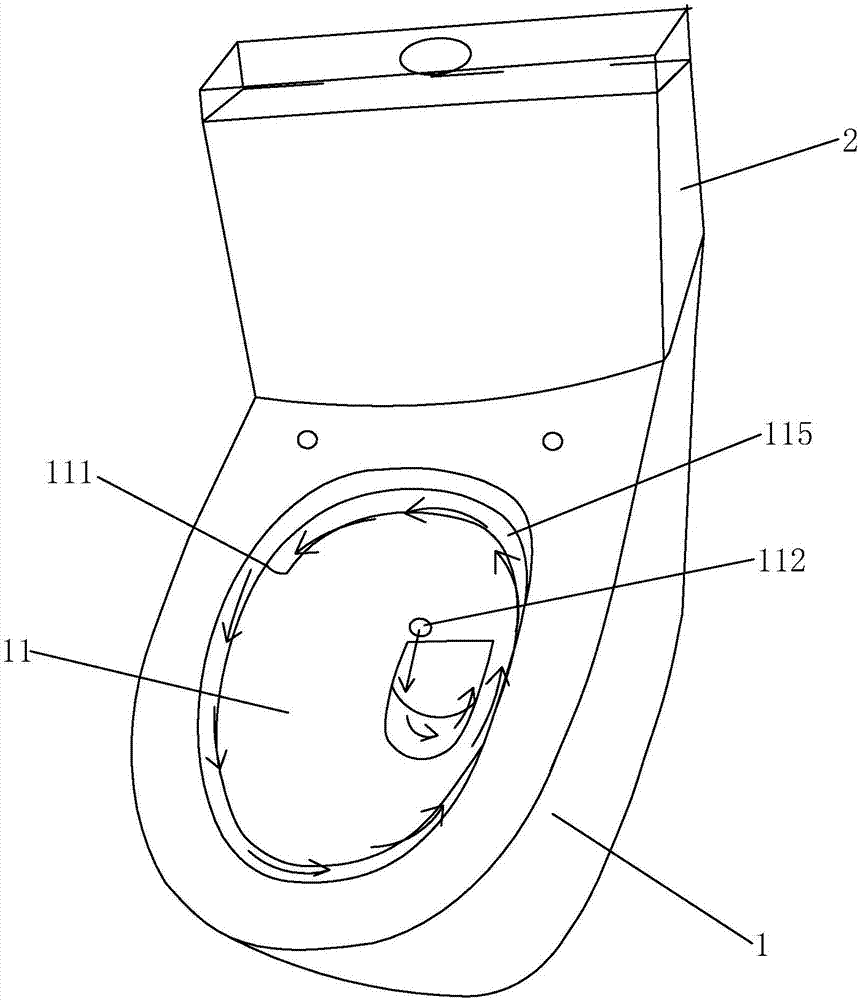

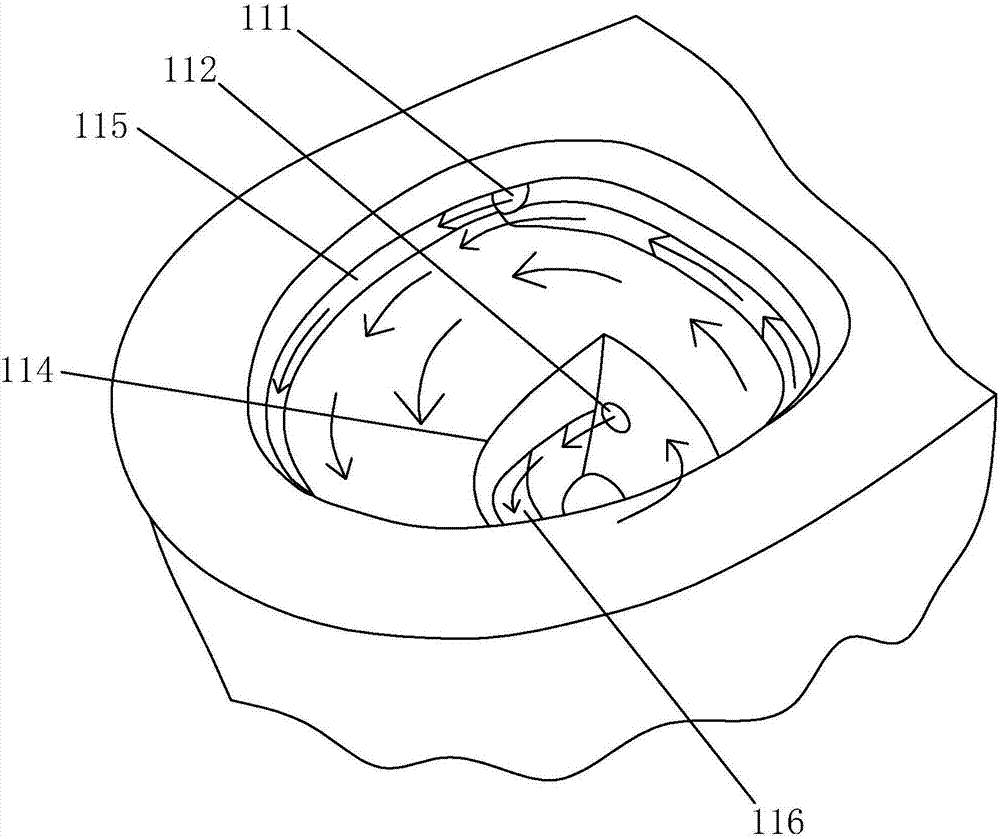

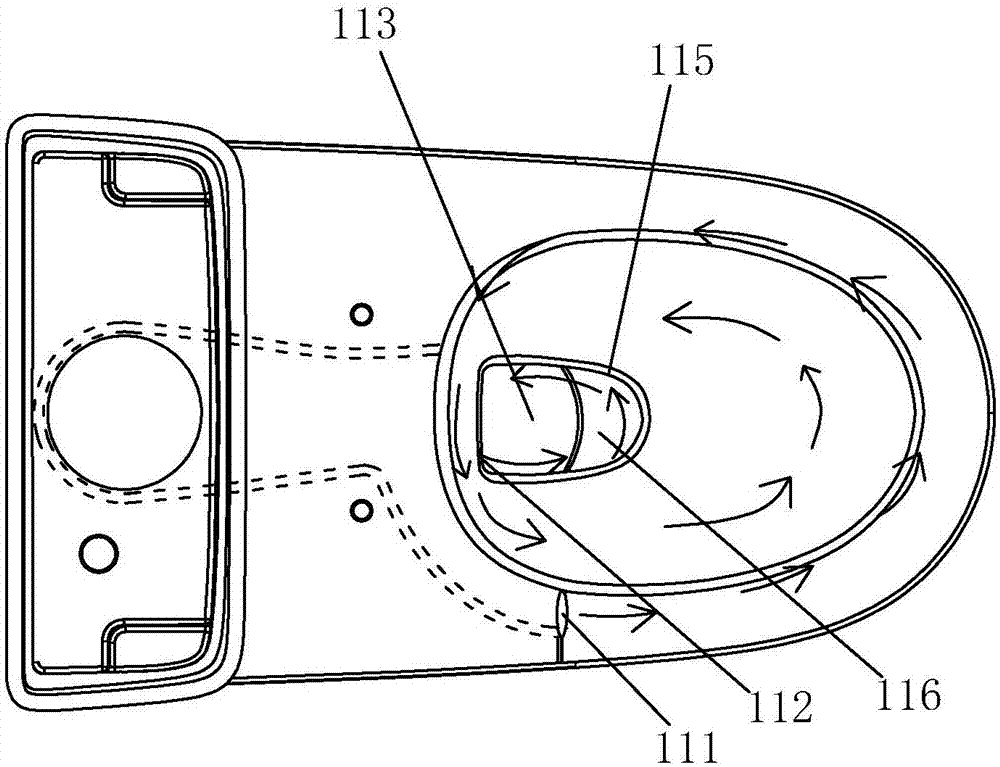

[0026] example, see Figure 1-Figure 4 As shown, a 3D super swirl siphon toilet of the present invention includes a toilet main body 1, and a water tank 2 is integrally formed at the top and rear of the toilet main body 1 . The toilet main body 1 is provided with a urinal 11, a siphon pipe 14, a flushing water channel 12, and a jetting water channel 13. The top of the urinal 11 is provided with a scrub hole 111, and the bottom of the urinal 11 is provided with a jet port 112, a sewage outlet 113, and a scrub hole. 111 is connected to the flushing water channel 12 , the spray port 112 is connected to the spray water channel 13 , and the sewage outlet 113 is connected to the siphon pipe 14 . The jetting water channel 13 is connected to the flushing water channel 12, and the flushing water channel 12 is connected to the drain port at the bottom of the water tank. The hole surface of the washing hole 111 is turned at an angle relative to the side of the toilet 11, so that the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com