Assembly type chemical spraying tube of plantation protection chemical spraying machine

A unit and assembly technology, which is applied in the direction of capturing or killing insects, applications, animal husbandry, etc., can solve the problems of time-consuming and troublesome, and achieve the effect of easy installation, consistent diameter and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

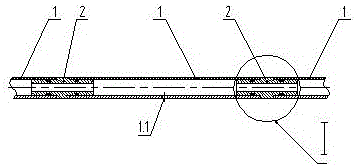

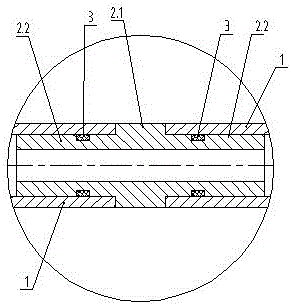

[0017] The assembled spraying pipe of the plant protection spraying machine shown in the accompanying drawing includes several spraying pipes 1 and several spraying pipe joints 2; the spraying pipe 1 is provided with spray holes 1.1; There is a shaft sleeve-shaped member with a shaft shoulder 2.1, and the end pipes 2.2 at both ends of the shaft shoulder 2.1 respectively extend into the inner holes at the ends of the spraying pipe 1 at both ends; the connection between the spraying pipe joint 2 and the spraying pipe 1 is provided with a sealed connection structure, The sealing connection structure includes the annular sealing groove on the outer wall of the spraying pipe joint 2 at the junction of the spraying pipe joint 2 and the spraying pipe 1, and the sealing ring 3 in the annular sealing groove. In this embodiment, the sealing ring 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com