A high-pressure cut-off/drainage spherical core valve

A ball core, high-pressure technology, applied in the direction of valve details, valve device, valve housing structure, etc., can solve the problems of excessive torque, etc., to achieve the effect of prolonging service life, high reliability, and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

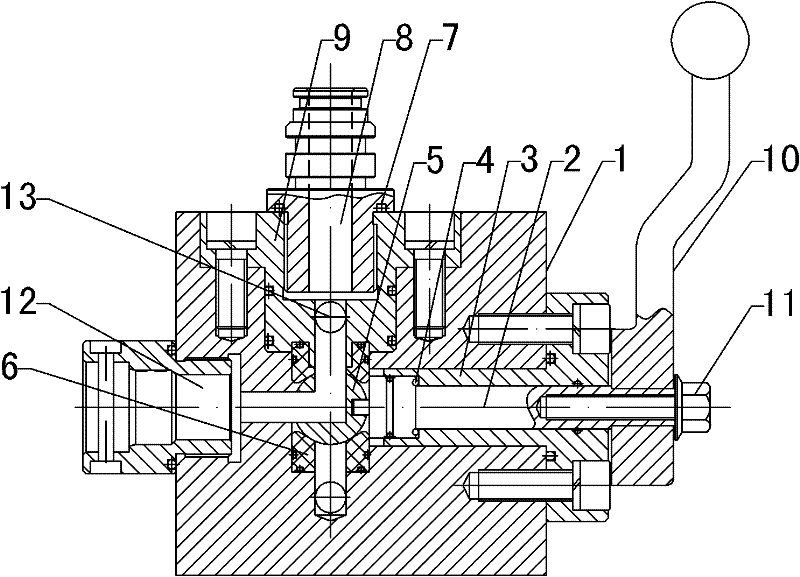

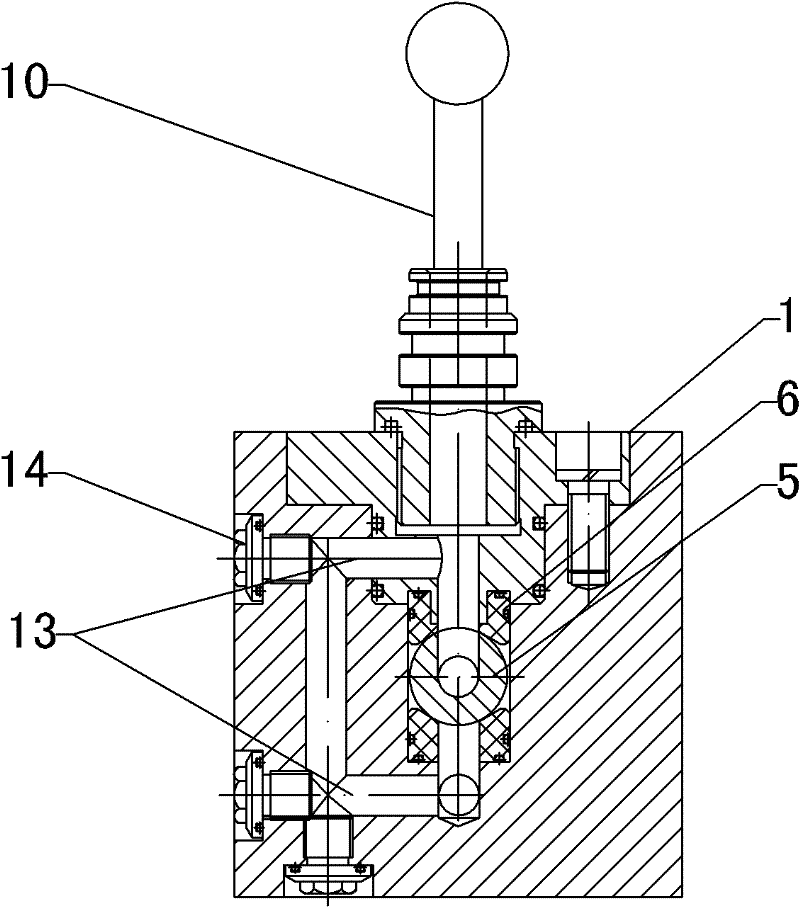

[0020] Refer to attached Figure 1~2 : Used as blowdown valve

[0021] The high-pressure cut-off / drainage spherical core valve includes a valve body 1, a valve core 5 and a valve seat 6. The valve core 5 is installed in the valve body 1 through the valve seat 6. The valve core 5 is spherical and has a keyway. The valve body 1 has two The side is provided with a liquid inlet 8 and a liquid outlet 12, the liquid inlet 8 is set on the upper surface of the valve body 1 and is threaded to connect the quick plug, the liquid outlet 12 is set on one side of the valve body 1 and is threaded to the quick socket, the liquid inlet 8 and the liquid outlet 12 communicate with the through hole in the spool 5, and two pressure balance passages 13 of equal aperture are added symmetrically on the upper and lower sides of the center of the spool 5 in the valve body 1, and the two pressures are balanced. One end of the channel 13 communicates with the main channel in the valve body 1 respectivel...

Embodiment 2

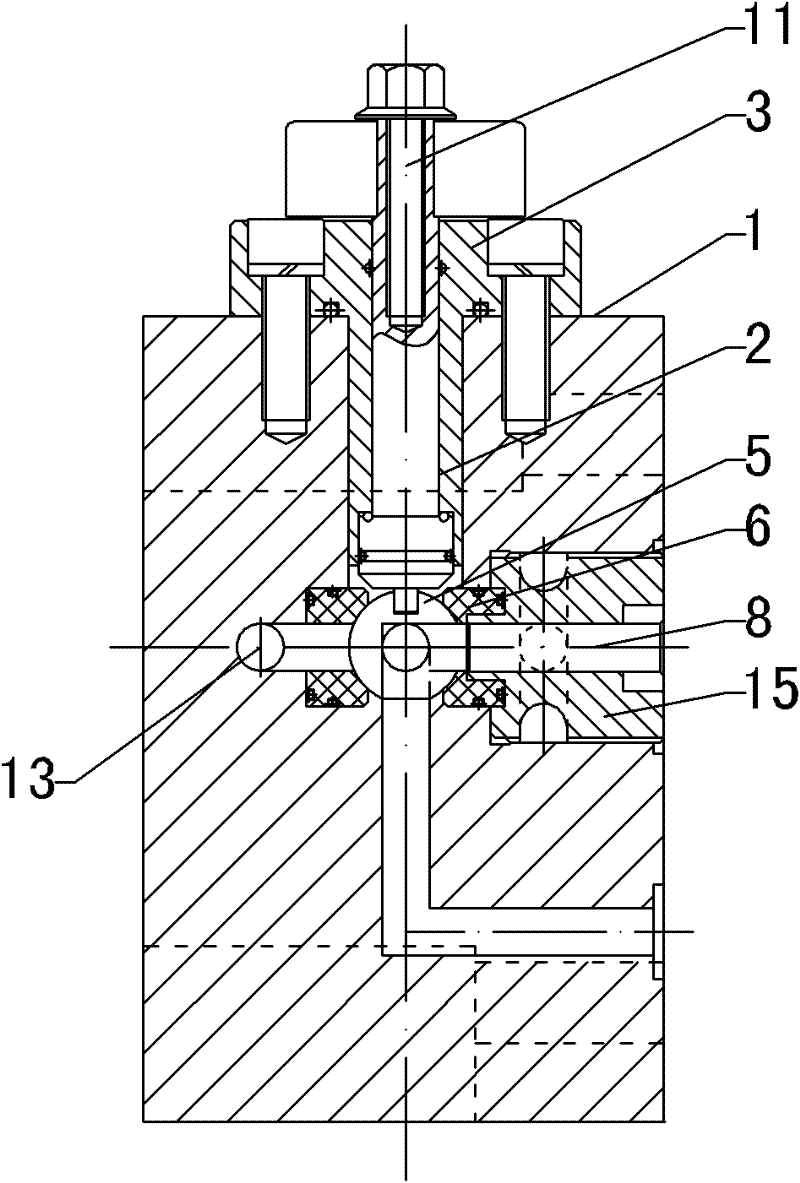

[0026] Refer to attached Figure 3-5 : Used as a stop valve

[0027] The utility model can also be used in the automatic backwashing system of the filter, and can be used as a cut-off valve, that is, the backwashing valve in the backwashing system; the liquid inlet 8 is arranged on the front surface of the valve body 1, and the liquid outlet 12 is arranged on the liquid inlet 8, on the same plane as the liquid inlet 8, the liquid inlet 8 is connected to the integrated valve seat system of the filter, the liquid outlet 12 is connected to the recoil pipe of the filter, and the valve body 1 at the liquid inlet 8 is equipped with a threaded sleeve 15 , Two pressure balance passages 13 are set in the valve body 1, on the left and right sides of the center of the valve core 5.

[0028] The working principle and working process are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com