Speed-controlling spraying device for sealant for construction engineering

A technology of construction engineering and spraying equipment, which is applied in the direction of construction, building components, building structures, etc., can solve the problems of inconvenient use, waste, too fast spraying flow rate, etc., and achieve the effect of increasing the spraying force and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

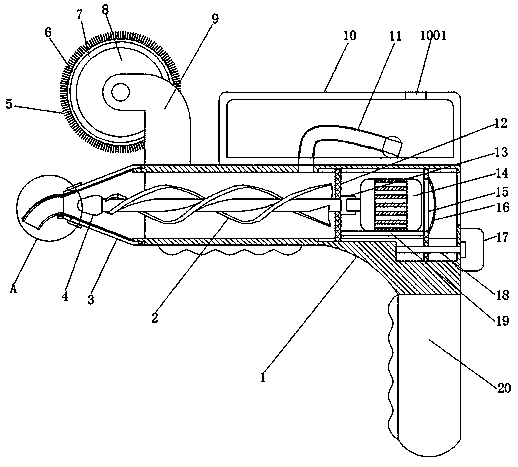

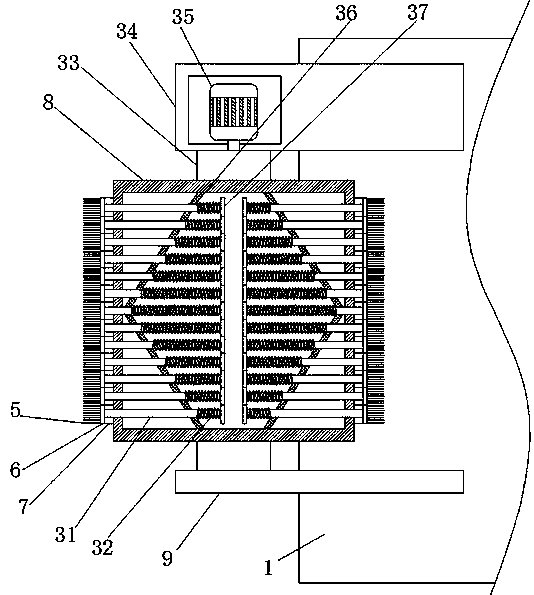

[0030] refer to Figure 1-3, a speed-controlled spraying device for sealant used in construction, comprising a main body 1, the top of the main body 1 is provided with a material storage box 10, the middle part of the main body 1 is provided with a first through hole, and the main body 1 is provided with a screw at the first through hole. Rod 2, one end of the screw rod 2 is welded with a moving body 4, the other end of the screw rod 2 is welded with a fixed sleeve 13, the main body 1 is provided with a fixed plate 19 at the bottom inner wall of the first through hole, and the top of the fixed plate 19 passes through Bolts are fixedly connected with a first motor 14, the output shaft of the first motor 14 is connected with the fixed sleeve 13 by a key, one side of the fixed plate 19 is welded with a moving plate 15, and one side of the moving plate 15 is provided with a threaded through hole, and the moving plate 15. A threaded rod 18 is provided at the threaded through hole. ...

Embodiment 2

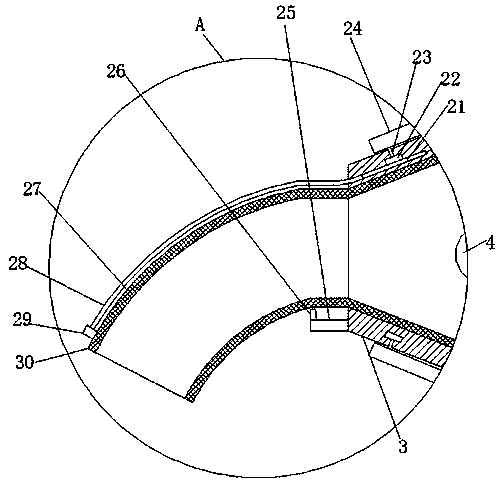

[0042] refer to Figure 4-5 , a speed-controlling spraying device for sealant used in construction projects. Compared with Embodiment 1, this embodiment, in order to increase the practicability of the device, facilitate the bending of the leather tube 30, and avoid wrinkles when the leather tube 30 is bent, the fixing body 26 A third elastic piece 38 is welded on one side, and the top of the third elastic piece 38 is bonded to the leather tube 30. When the leather tube 30 bends, the leather tube 30 will bend along the third elastic piece 38 without wrinkling, which can effectively avoid Bending and wrinkling of the hose affect the ejection of the sealant.

[0043] When in use, the threaded sleeve 22 is rotated by rotating the rotating ring 24, and the threaded sleeve 22 drives the moving piece 21 to move inside the first chute through the thread, and the moving piece 21 pushes the second elastic piece 28 to move, and the other end of the second elastic piece 28 Push the fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com