Cleaning device for electric blanket

A cleaning device and a technology for electric blankets, which are applied to the configuration of equipment for processing textile materials, removing liquid/gas/vapor by suction, and treating textile materials by spraying/jetting, etc. , troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further detailed explanation through specific implementation mode below:

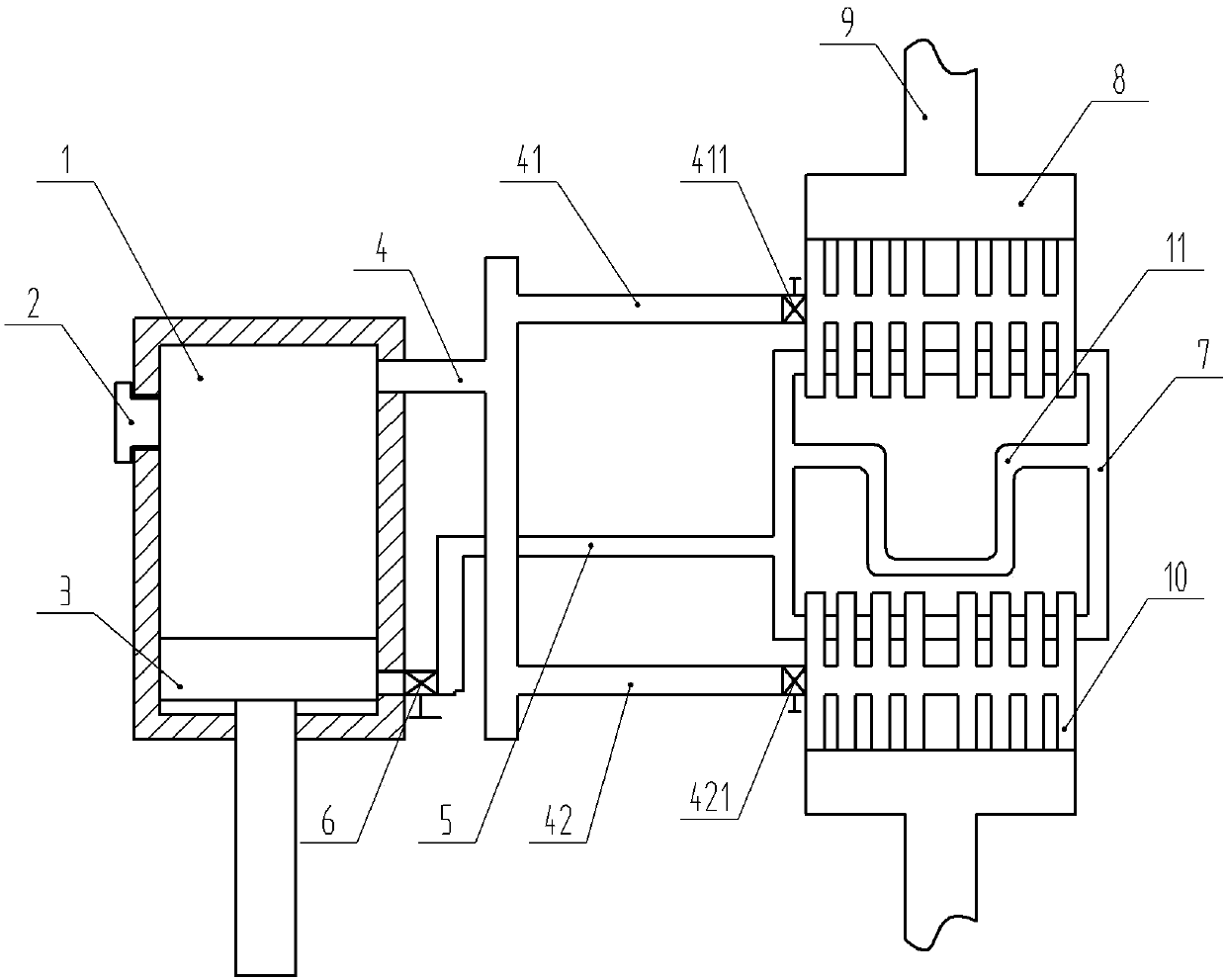

[0023] The reference signs in the accompanying drawings of the description include: inflatable box 1, cork 2, piston rod 3, first air delivery pipe 4, first branch pipe 41, second branch pipe 42, first valve 411, second valve 421, The second air pipe 5, the third valve 6, the pressure pipe 7, the storage chamber 8, the water pipe 9, the injection pipe 10, and the U-shaped pipe 11.

[0024] The embodiment is basically as attached figure 1 Shown: a cleaning device for electric blankets, including pressure tube 7 and U-shaped tube 11, pressure tube 7 is a rectangular frame, the upper part of pressure tube 7 and U-shaped tube 11 is made of steel material, pressure tube 7 and U-shaped tube 11 The lower part is made of plastic material, the U-shaped tube 11 is arranged in the pressure tube 7, and the two ends of the U-shaped tube 11 communicate with the pressure tube 7, and the left side of the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com