Air splitting type spouting head

A shotcrete and air-type technology, applied in wellbore lining, tunnel lining, underground chamber, etc., can solve the problems of uneven spraying of the shotcrete head, reverse wind, slurry leakage, etc., save raw materials, improve spraying strength, The effect of increasing the spray distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

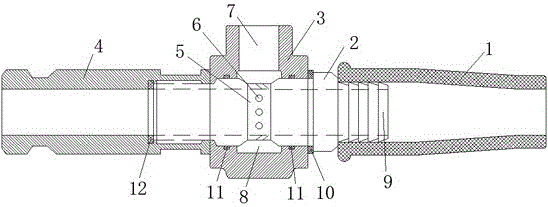

[0018] Attached below figure 1 To elaborate on the present invention, an air-distributing spray head includes a connecting pipe 4 and a nozzle 1, and is characterized in that: the connecting pipe 4 is connected to the nozzle 1 through the air mixing pipe 2, and is opened around the outer wall of the air mixing pipe 2. There is an annular groove 5, and the bottom of the annular groove 5 is uniformly provided with amplifying holes 6, and each amplifying hole 6 is oblique to the direction of the nozzle 1 from the outside to the inside, and the inclination angle of each amplifying hole 6 is consistent, and the annular groove 5 is covered with There is a gas mixing tube cover 3, and a side port 7 communicating with the outside world is provided on the gas mixing tube cover 3, and the bottom of the side port 7 communicates with the annular groove 5.

[0019] The above is the basic implementation mode of the present invention, further improvement, optimization and limitation can be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com