Preparation method of rubber lining screw rod

A screw and rubber lining technology, applied in the coating and other directions, can solve the problems of difficult to increase the pressure of the mold channel, different colloid adhesion ability, uneven rubber lining, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

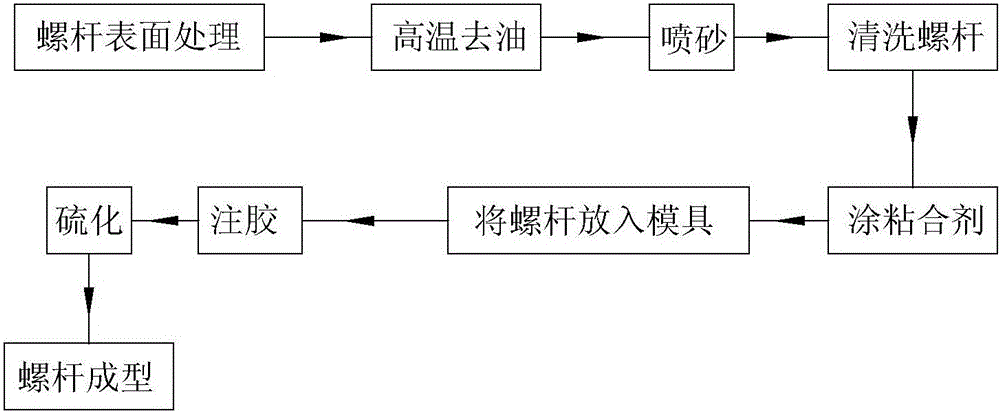

[0022] Such as figure 1 As shown, the preparation method of the rubber-lined screw of the present embodiment comprises the following steps:

[0023] (1) Degrease and sandblast the outer surface of the screw, then clean and dry; specifically, use an oven to degrease the screw at high temperature, and the temperature is controlled at 200°C to 250°C, and then spray the parts that need to be lined with rubber Sand, then clean the screw with a volatile solvent and dry it. The volatile solvent can be acetone or xylene;

[0024] (2) Apply an adhesive layer on the outer surface of the dried screw; the adhesive can be selected according to the rubber material used when lining the rubber;

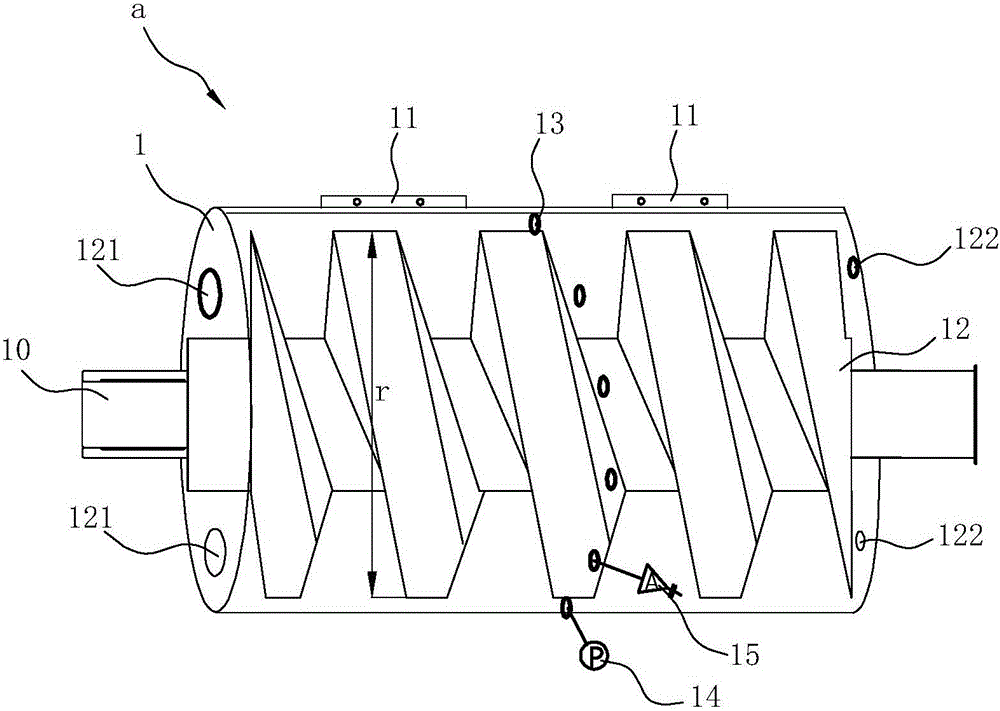

[0025] (3) Put the screw into the screw mold a for injection: as figure 2 As shown, the screw mold a is an open and close cylindrical structure, and the purpose ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com