Pipe horizontal moving device of automatic pipe packaging machine

A technology of automatic packaging machine and translation device, applied in packaging and other directions, can solve the problems of high labor intensity, untimely transportation, and low labor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

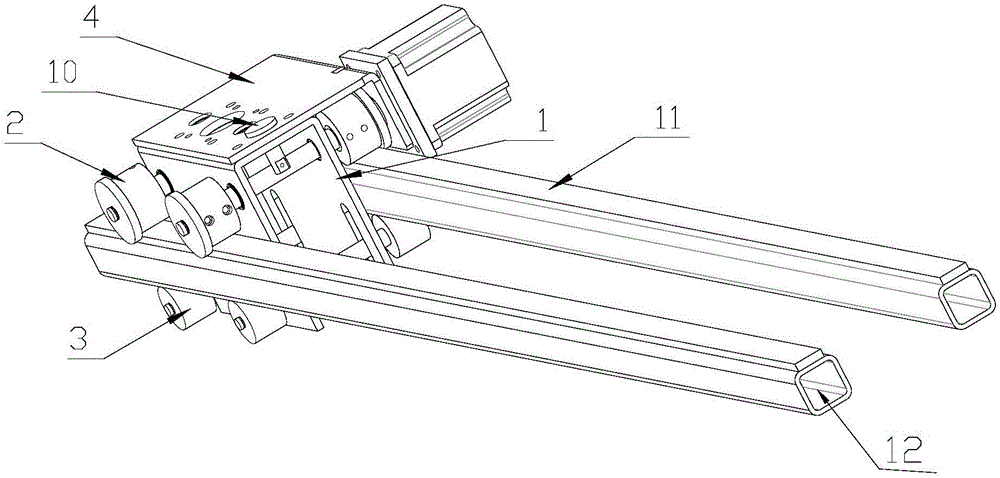

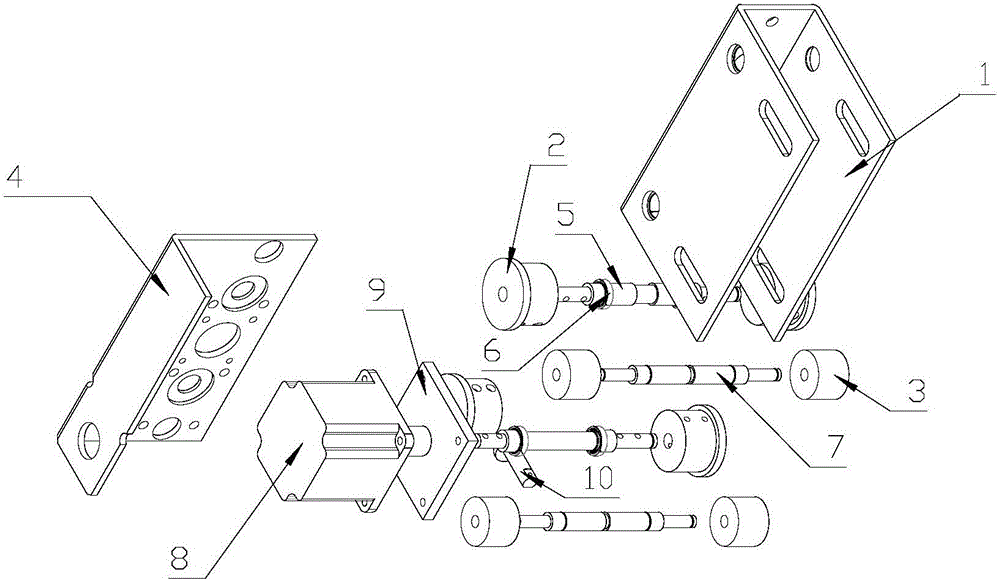

[0011] Such as figure 1 , 2 As shown, in the preferred embodiment of the pipe translation device of the automatic pipe packaging machine of the invention, it includes a bracket 12, a guide rail 11 arranged on the bracket, and a translation mechanism, and the translation mechanism includes an upper guide rail arranged on the guide rail Wheel 2, lower rail wheel 3, connecting shaft 5 connecting the upper rail wheel, connecting shaft 7 connecting the lower rail wheel, bearing 6 supporting the connecting shaft, shaft support frame 1, driver 8, installing the driver Support 4, drag hook 10.

[0012] In the pipe end cap grabbing device of the pipe automatic packaging machine of the present invention, the speed of the driver 8 is controllable, the working time is controllable, the forward and reverse rotation can be realized, and the speed and delivery time of the pipe can be controlled.

[0013] In the pipe end cap grabbing device of the pipe automatic packaging machine of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com