Fast installing picture fixing rod

A technology for fixing rods and frames, which is applied to display devices, signs, instruments, etc., can solve the problems of rigid frame fixing methods, insufficient fixed frames, and numerous disassembly and assembly procedures, etc., and achieves high reliability and convenient operation and use , the effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

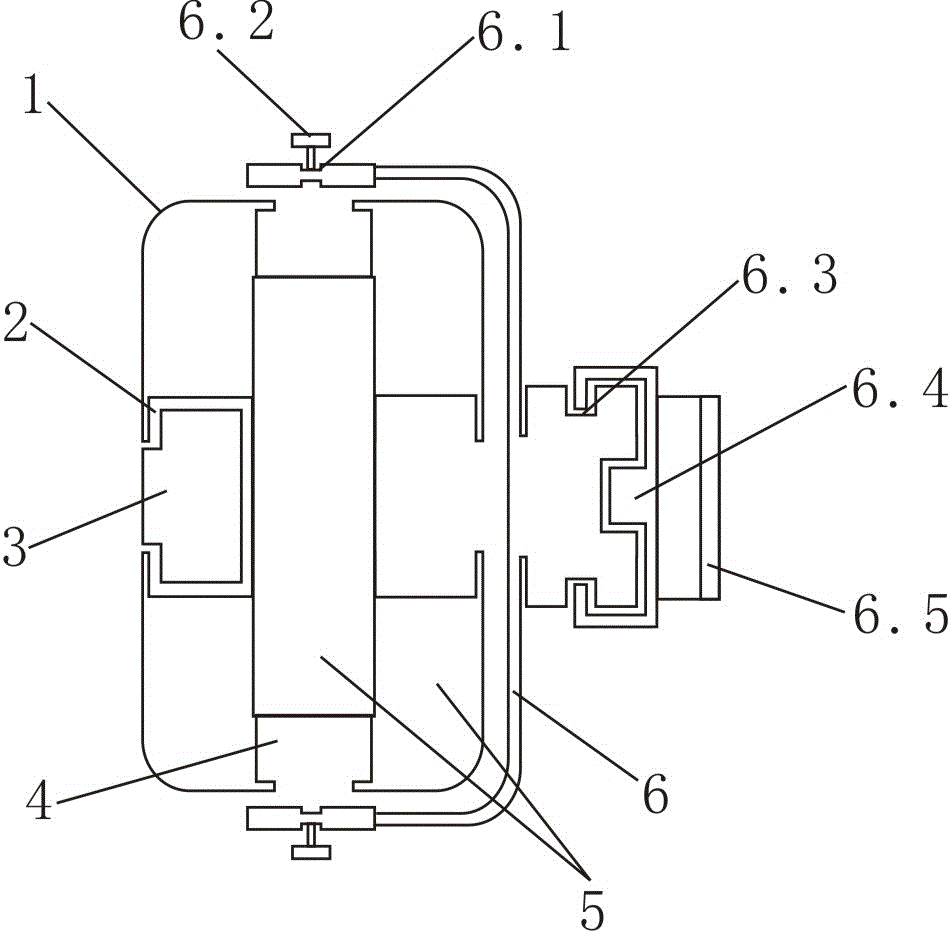

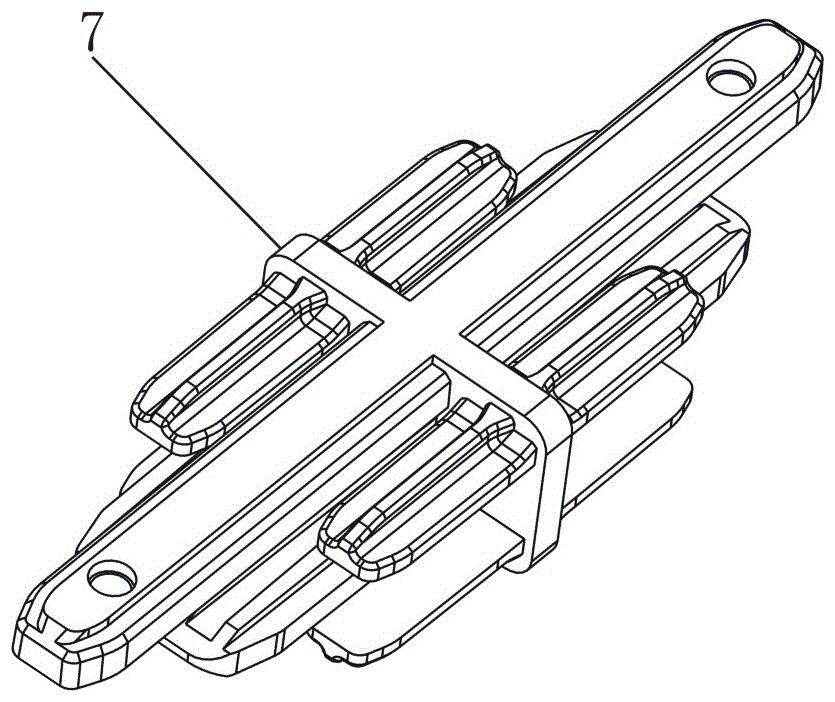

[0025] Now refer to the attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 , combined with the embodiment description as follows: the quick installation frame fixing rod according to the present invention includes a bar body 1, which is characterized in that at least one side of the two wide surfaces of the bar body 1 is provided with a card slot 2, and the card slot 2 is provided with a Binding strip 3 is arranged, and described binding strip 3 can be used for binding frame.

[0026] Further, at least one of the upper and lower narrow surfaces of the strip body 1 is provided with a fixing groove 4 .

[0027] Further, at least one of the two ends of the bar body 1 is provided with a mounting hole 5 .

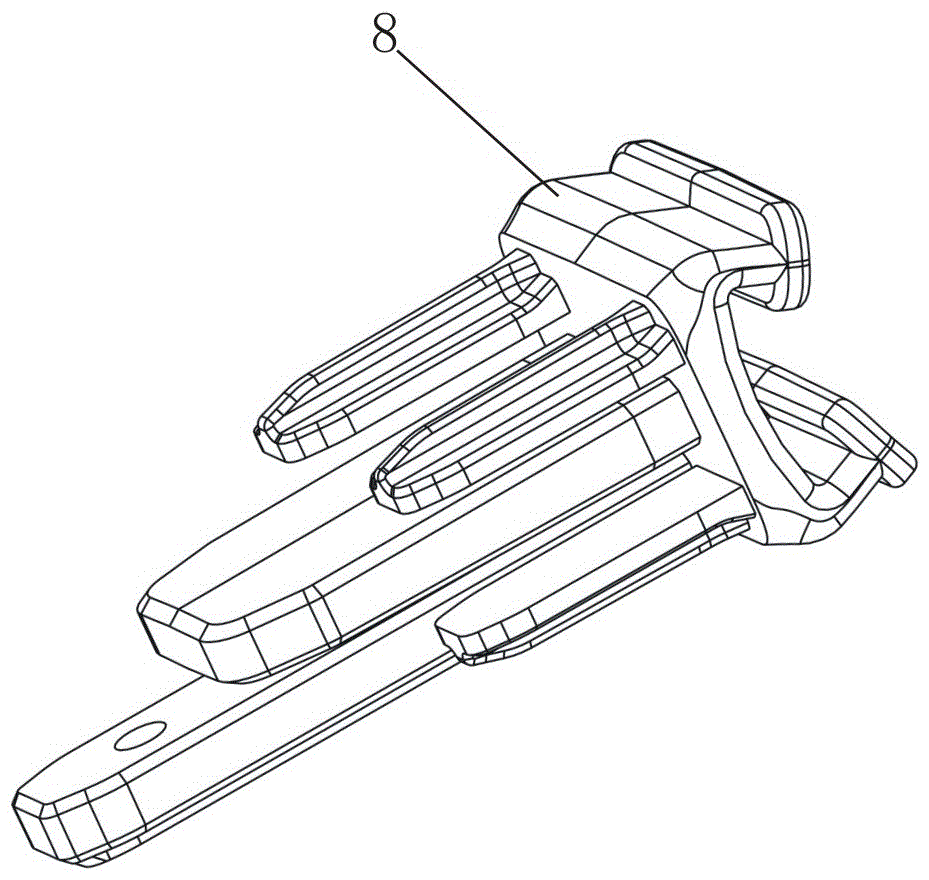

[0028] Further, the bar body 1 is clamped with a clamp piece 6, and the clamp piece 6 is provided with a fixing screw hole 6.1, and the fixing screw hole 6.1 is provided with a fixing screw 6.2, and the clamp piece 6 passes through the fixing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com