A variable speed cutter device for absorbent articles

An absorbent and article-based technology, applied in the field of variable-speed cutter devices, can solve the problems of long recoding time and high manufacturing cost, and achieve the effects of low manufacturing cost, equipment cost saving, and convenient recoding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

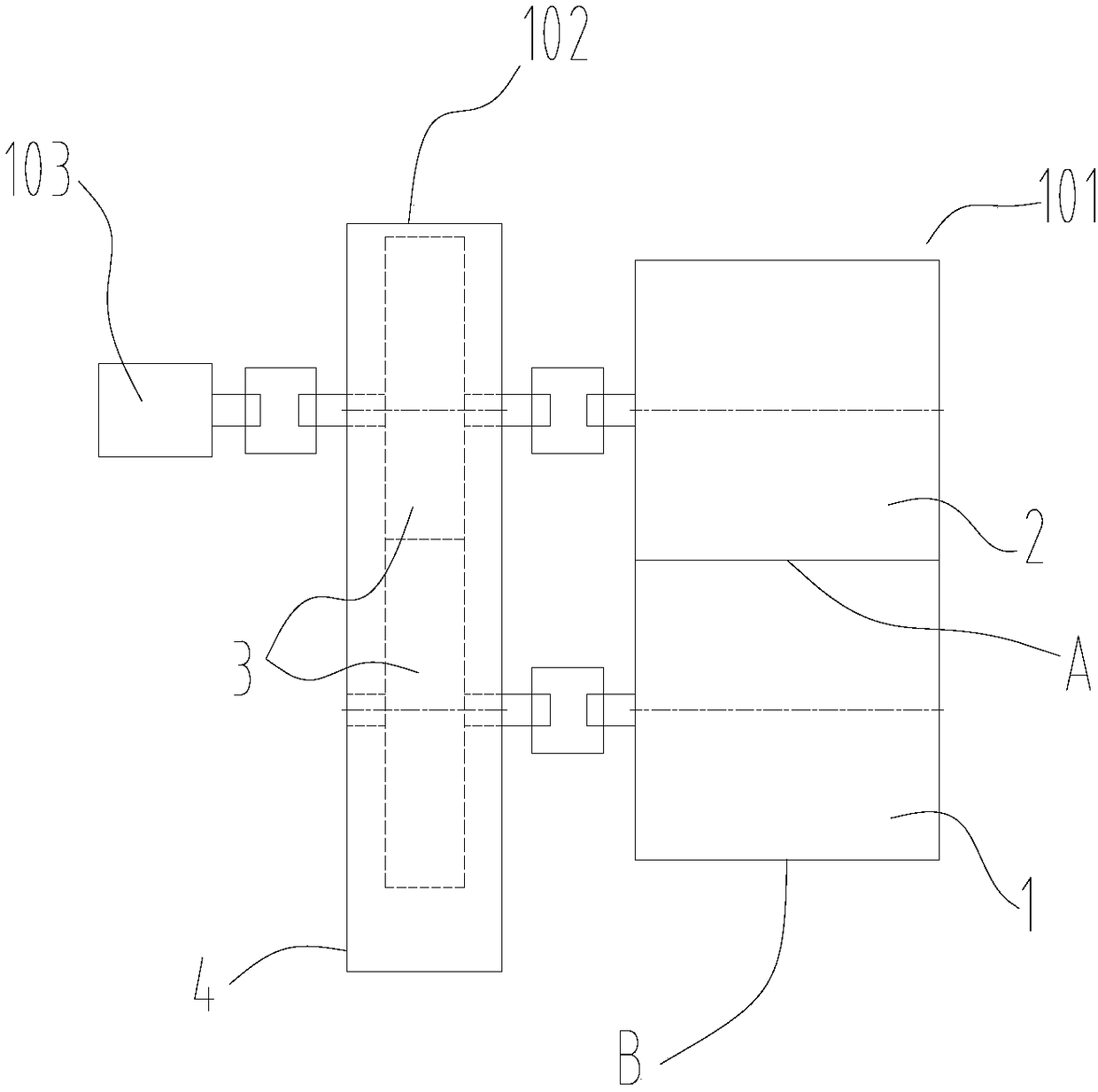

[0014] Please also refer to Figures 1 to 2 , a variable speed cutter device for absorbent articles, including a rotary cutter assembly 101 , a variable speed assembly 102 and a drive motor 103 .

[0015] Wherein, the rotary cutter assembly 101 includes a lower anvil roll 1 and an upper knife roll 2 .

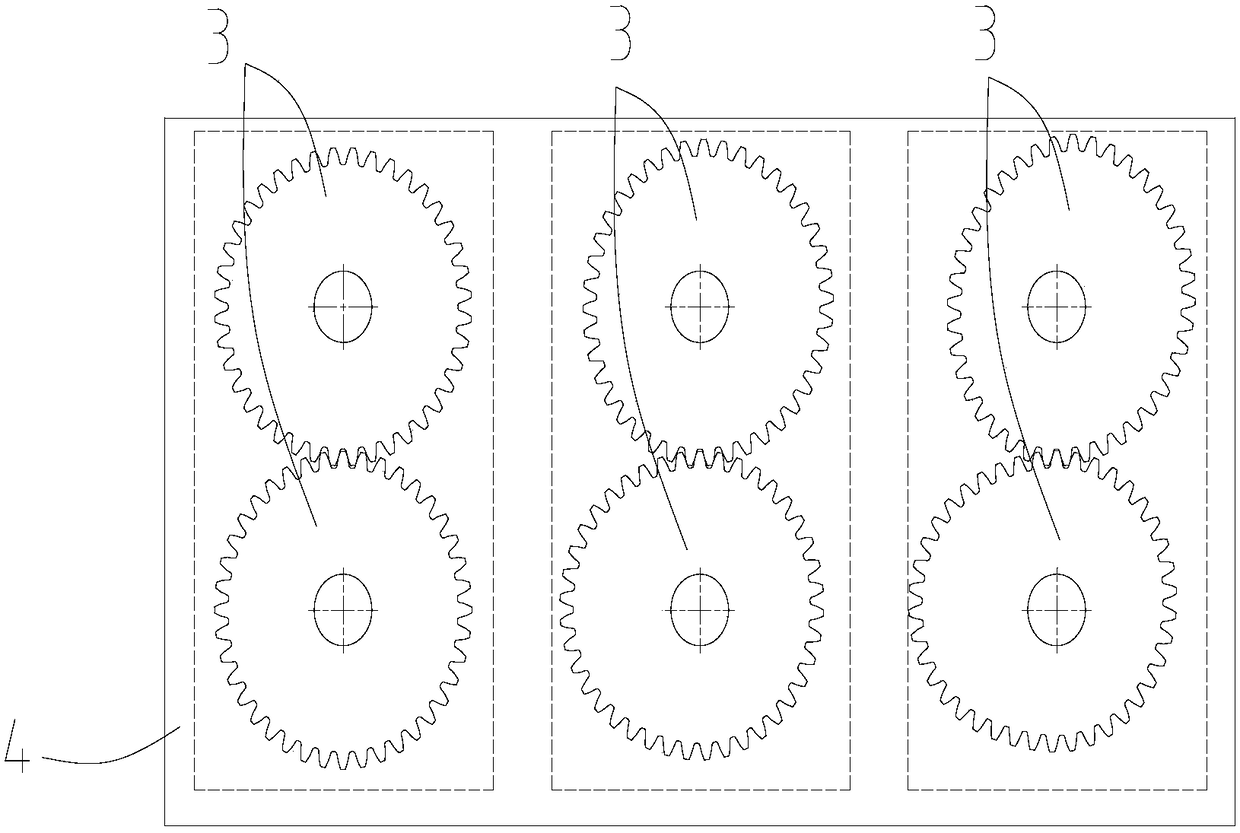

[0016] The transmission assembly 102 is composed of three non-circular gear pairs 3 . Any pair of non-circular gear pairs 3 in the transmission assembly 102 is detachably connected to the anvil roller 1 and the knife roller 2 through a coupling and a pivot. The speed change assembly 102 is installed in the gear box 4, and the non-circular gears in the upper row in the speed change assembly are connected with the drive motor 103 through a coupling. The position of the speed change assembly 102 relative to the rotary cutter assembly 101 is movable.

[0017] The first angular velocity of the anvil roller 1 in the material cutting zone A near the cutter roller 2 is less than or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com