Full high titanium heavy slag concrete mixed with micropowder and its preparation method

A high-titanium heavy slag and concrete technology, applied in the field of concrete, can solve the problems of high utilization cost, pollute the environment, occupy land, etc., and achieve the effect of reducing production costs and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

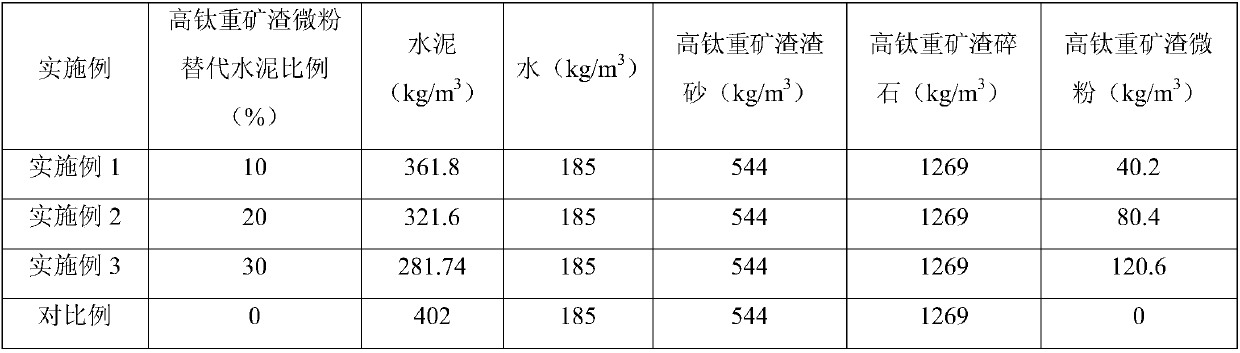

[0022] The raw material ratio described in Table 1 is adopted to obtain the full high titanium heavy slag concrete mixed with micropowder, and the preparation of the full high titanium heavy slag concrete mixed with micropowder obtained in Examples 1-3 is all prepared according to the following methods:

[0023] Weigh out the required cement, water, high-titanium heavy slag sand, high-titanium heavy slag gravel and high-titanium heavy slag micropowder according to the corresponding ratio of raw materials. In the mixer, stir for 60s, add the uniformly mixed cement and high-titanium heavy slag micropowder mixture into the mixer, and stir for 120s to make the cement, high-titanium heavy slag sand, high-titanium heavy slag gravel and high-titanium heavy slag micropowder four Mix evenly, then add water while stirring, and continue stirring for 120s after adding water until the workability of the concrete is good. Pouring, vibrating and curing according to standard requirements.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com