High-pressure jet grouting waterproof curtain support impervious curing material as well as preparation method and application thereof

A water-stop curtain and high-pressure rotary spraying technology, which is applied in the field of road engineering materials, can solve the problems of limiting the application of high-pressure rotary spraying water-stop curtains, poor anti-seepage ability of water-stop curtains, and low reliability of material design, and achieves a simple preparation method Easy to operate, solve the problem of reduction and utilization, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Take out an appropriate amount of sintered red mud, perform preliminary crushing, dry at 105°C for 48 hours, cool the dried sintered red mud to room temperature, grind it with a planetary ball mill, and take out the ground red mud Pass through a 1mm square hole sieve and set aside.

[0036] (2) Take an appropriate amount of fly ash, use a planetary ball mill to grind the fly ash (destroying the vitreous body of the fly ash to make it react better), and pass it through a 0.075 square hole sieve for later use.

[0037] (3) Weigh 800g of ordinary Portland cement to obtain component A, weigh 160g of prepared sintering red mud and 40g of fly ash, mix them evenly to obtain component B, and weigh 145g of GM activator to obtain component A Score C.

[0038] (4) Add water and stir the mixed components A, B and C according to the water-cement ratio of 0.45.

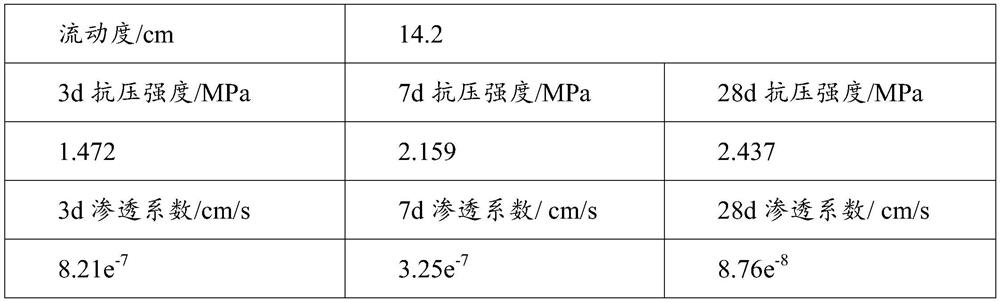

[0039] The high-pressure rotary spraying water-stop curtain slurry prepared in Example 1 was used to obtain a high-p...

Embodiment 2

[0043] (1) Take out an appropriate amount of sintered red mud, perform preliminary crushing, dry at 105°C for 48 hours, cool the dried sintered red mud to room temperature, grind it with a planetary ball mill, and take out the ground red mud Pass through a 1mm square hole sieve and set aside.

[0044] (2) Take an appropriate amount of nickel slag, use a planetary ball mill to grind the nickel slag, and pass it through a 0.075 square hole sieve for later use.

[0045](3) Weigh 700g of ordinary Portland cement to obtain component A, weigh 250g of prepared sintering red mud and 50g of nickel slag, mix well to obtain component B, and weigh 72.5g of quicklime to obtain component c.

[0046] (4) Add water and stir the mixed components A, B and C according to the water-cement ratio of 0.45.

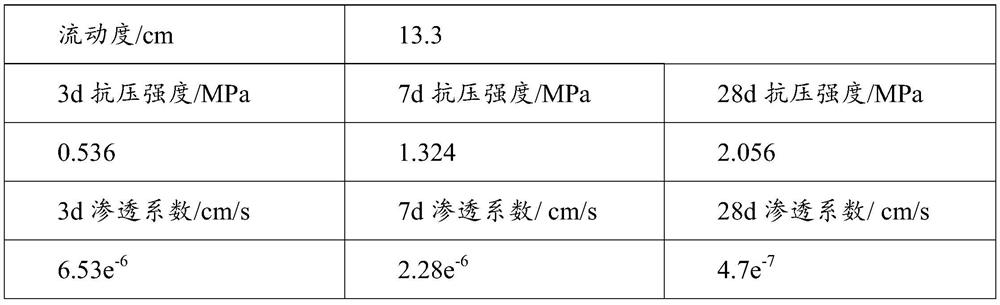

[0047] The high-pressure rotary spraying water-stop curtain slurry prepared in Example 2 was used to obtain a high-pressure rotary spray water-stop curtain through high-pressure jet technology...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com