A kind of super early strength concrete admixture and preparation method thereof

A concrete admixture, ultra-early-strength technology, applied in the field of concrete admixtures, can solve the problems of early-strength effect, etc., and achieve the effect of rapid increase in early-strength strength, stable increase in later-stage strength, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

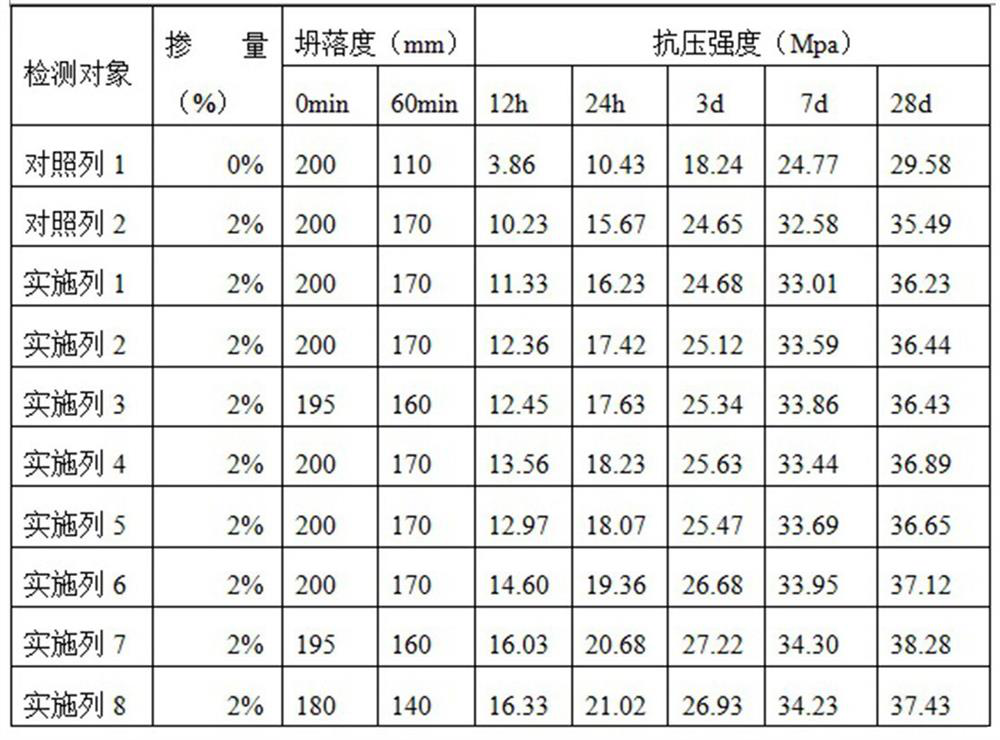

Examples

Embodiment 1

[0031] Take 14 parts of polycarboxylate water reducer, 6 parts of viscosity-reducing polycarboxylate water reducer and 1 part of retarder by weight, add 72 parts of water, and mix well; add 2 parts of modified alcohol amine and 5 parts of sodium thiocyanate 1. Add 0.1 part of air-entraining agent and 0.05 part of defoamer into the mixed solution and mix evenly; according to the pH value of the solution, add an appropriate amount of pH regulator to adjust the pH value of the solution to 7-9.

[0032] Implementation column 2:

[0033] Take 14 parts of polycarboxylate water reducer, 6 parts of viscosity-reducing polycarboxylate water reducer and 1 part of retarder by weight, add 70 parts of water, and mix well; add 4 parts of modified alcoholamine and 5 parts of sodium thiocyanate , 0.1 part of air-entraining agent and 0.05 part of defoamer are added to the mixed solution, and mixed evenly; an appropriate amount of pH regulator is added to adjust the pH value of the solution to 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com