Anti-friction nut

A nut and nut body technology, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problem of large friction between the nut and the tray, and achieve the effect of improving the effective preload, reducing fracturing and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

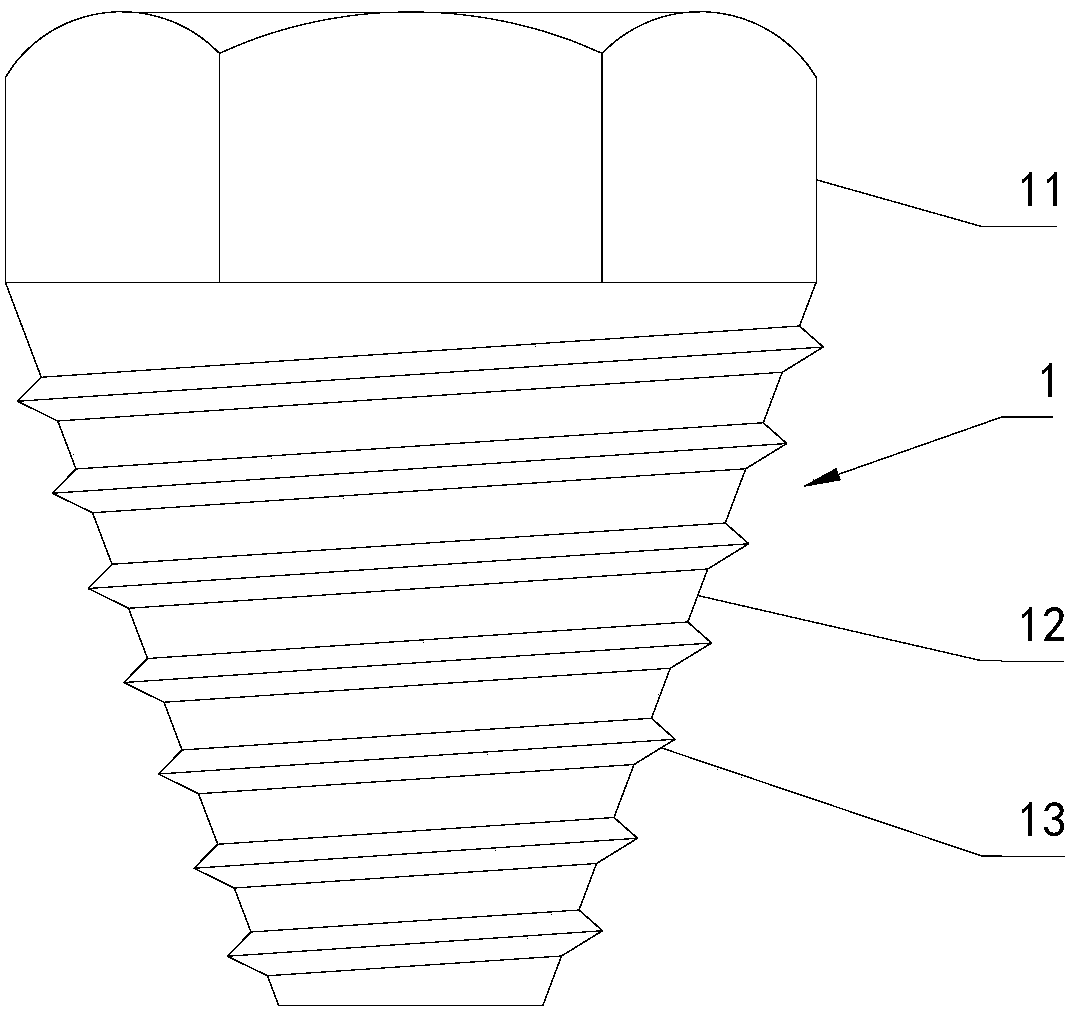

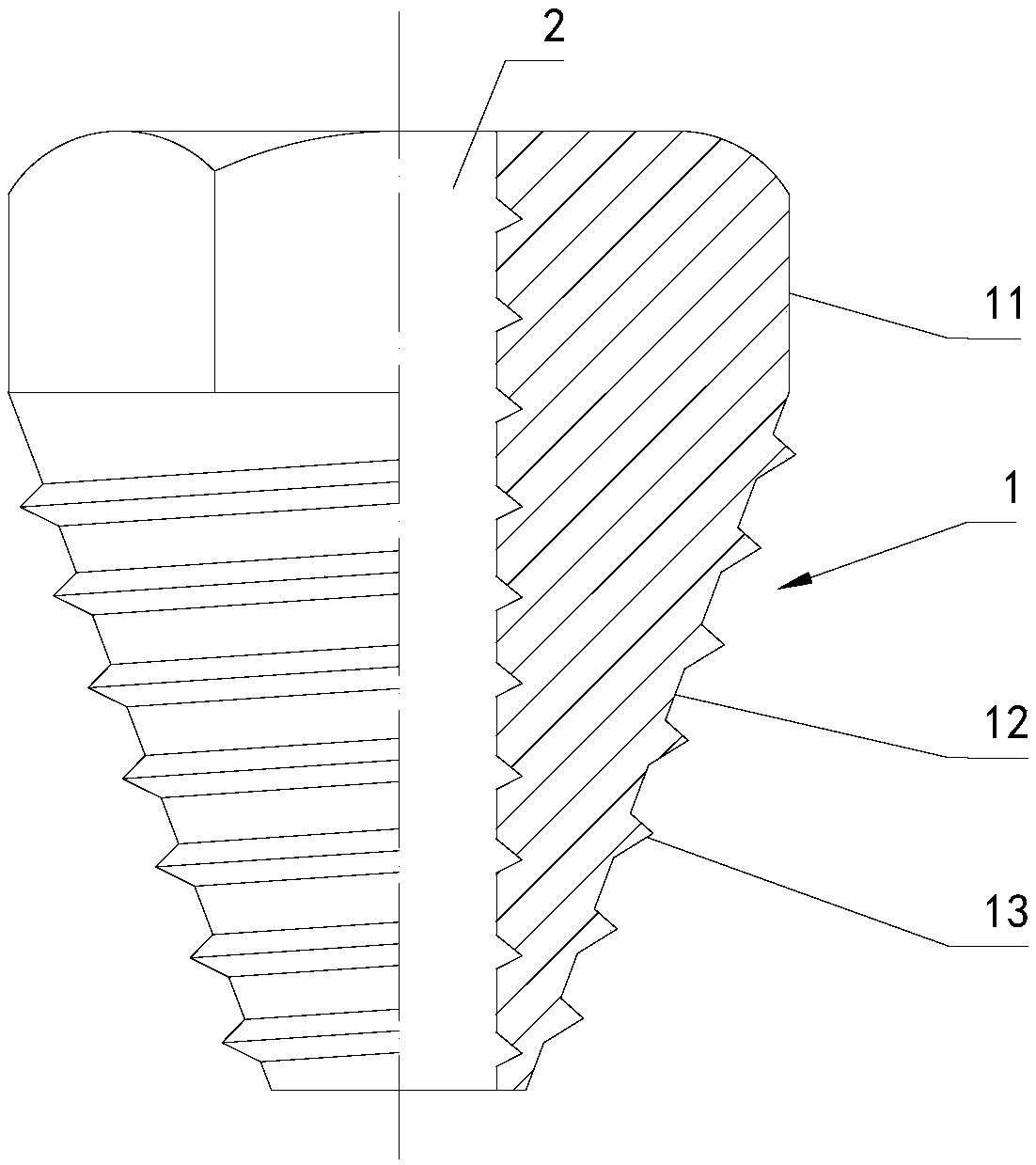

[0034] see figure 1 , figure 2 As shown, the present embodiment provides an anti-friction nut; figure 1 The front view of the anti-friction nut provided for this embodiment; in order to show the structure more clearly, figure 2 for figure 1 Half cutaway view of the antifriction nut shown.

[0035] see figure 1 , figure 2 As shown, the anti-friction nut provided in this embodiment is applied to anchor rods, especially to fiberglass anchor rods, and includes a nut body 1 and a threaded through hole 2 fixed on the nut body 1. The nut body 1 includes a threaded through hole The first part 11 and the second part 12 are fixedly connected in sequence in the axial direction of 2, and the threaded through hole 2 runs through the first part 11 and the second part 12. Wherein, the anti-friction nut is threadedly connected with the rod body of the anchor rod through the threaded through hole 2 .

[0036] Along the axial direction of the threaded through hole 2 , the cross-sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com